Introduction

Managing the release of non-native species can be accomplished by placing barriers at various points on an aquaculture facility. These barriers can include screens, covers, control structures, and ponds (Figure 1). Using these structures, the goal of aquaculture producers should be to prevent release of non-native species in compliance with Florida Aquaculture Best Management Practices (BMPs; FDACS 2015). Further, many of the structures discussed below are also effective in addressing and maintaining compliance with the discharge requirements of the BMPs.

Credit: Reprinted from Hill et al. (2016)

This document is the third in a four-part series devoted to educating industry and other stakeholders on the importance of preventing escape of non-native species from aquaculture facilities as well as strategies for non-native species containment and regulatory compliance (Tuckett et al. 2016a; Hill et al. 2016; Tuckett et al. 2016b). Producers can use a combination of structural barriers discussed in this publication and facility management strategies discussed in Part 4 to achieve compliance with BMPs (Part 1).

Series Contents

- Part 1: General Considerations and Regulations—introduces series, explains why non-native species containment is important, provides information on regulations, including the Florida Aquaculture Best Management Practices (BMPs) rule, describes the BMP inspection process, and provides advice on achieving compliance

- Part 2: Facility Evaluation Strategies—describes farm layouts, how fish escape, and a process that aquaculturists can complete to identify potential escape points on their farms

- Part 3: Structural Strategies—provides information on structures and barriers that can prevent escape

- Part 4: Operational Strategies—describes operational and management strategies to prevent escape

Strategies

As noted in Part 2 of this series (Hill et al. 2016), non-native species can escape from aquaculture facilities through a variety of pathways, including through aquaculture effluents, carry-off by birds, and vandalism and theft. To minimize the escape of non-native species from aquaculture facilities, producers should be aware of the benefits and drawbacks of each structure and their associated costs and effectiveness in limiting escape (Table 1). Producers must also be aware of additional regulations for rearing species that are classified by the Florida Fish and Wildlife Conservation Commission as conditional i.e., restricted by FDACS). In these cases, additional escape barriers and operational strategies must be in place. Producers should be sure to reference the current FDACS rules (FDACS 2015) and also Part 1 in this series. Structural strategies for preventing the release of organisms can include a combination of the following barriers:

- Screens on aquaria and vats

- Filters and screens on pumps and discharge pipes

- Covers on aquaria, vats, and ponds

- Riser-board and trickle-flow control structures

- Vegetated swales

- Created wetlands

- Recapture ponds

- Detention ponds (ponds with effluent leading off-site)

- Retention ponds (ponds with no effluent leading off-site)

- Recirculating systems

- Zero discharge

- Fencing and lighting

Screens

The use of mesh screens is one of the easiest and most cost-efficient strategies to prevent the escape of non-native species while also maintaining compliance with Aquaculture BMPs (Figure 2). When fitting screens on holding systems, pumps, and ditches, consider the following criteria:

- able to capture the smallest stage of the organism (egg to adult)

- specific to the species being produced and the type of discharge

- placed at multiple points along the effluent (redundant barriers)

Credit: UF/IFAS Extension

Screen Mesh Size

Mesh size can vary widely, from a small fraction of an inch up to and exceeding one inch. However, fine mesh material is more prone to fouling, and producers should consider the tradeoff between preventing the release of small life stages, eggs and larvae, and the potential for nuisance algal growth on the screen. If fine mesh becomes clogged, this presents additional challenges including the spill-over of holding systems and the ultimate release of non-native species. Few cultured fish species lay very small eggs, those less than 1/32 inch. Thus, screens smaller than this size should be generally avoided. Ultimately, mesh size of less than ¼ inch may be impractical for most production aquaculture uses. Fine and coarse screens can be found through a variety of sources (Appendix).

Screen Specificity

Screening should be specific to the species being reared and the type of discharge the screen will receive. Smaller mesh sizes are needed for livebearers and tilapia, which will readily reproduce in most systems. The type of discharge will also affect the type of mesh; smaller sizes for packing house effluents and larger sizes for pipes that handle pond effluents. In addition to considerations for mesh size, mesh material and the specific task should also be considered. For example, screens can be used on pump intake lines during the pond drawdown process; this practice is best accomplished with metal or hard plastic baskets, which can be quickly attached and removed (see Tuckett et al. 2016b for an example). Mesh material should also be considered when screens are placed in ditches because these screens will be exposed to more abrasion and sunlight. UV degradation due to daily sunlight exposure can damage screens and lead to failure. Ultimately, screens with small mesh will foul quickly and will lead to additional problems such as flooding.

Screen Use and Locations

Screens are most effective when they are consistently and redundantly used on aquaria, vats, dewatering pumps, and control structures. Redundancy in the use of barriers is one of the best strategies to minimize escape. When considering the placement of screens, consider the flow of water from the holding system (pond, vat, aquaria, etc.) to the property boundary (Hill et al. 2016). As an example, during the packing process non-native species can fall into the trench drain. Therefore, in the packing house and other greenhouses, screens can be present on trench drains leaving the building and further down the line at settling basins and detention ponds. Screens can also be placed on the pump intake, because some fish can survive passage through the pump and later escape the property. A facility with screens on all holding systems, pipes, and pumps, in the absence of other issues, is one that often meets BMP standards.

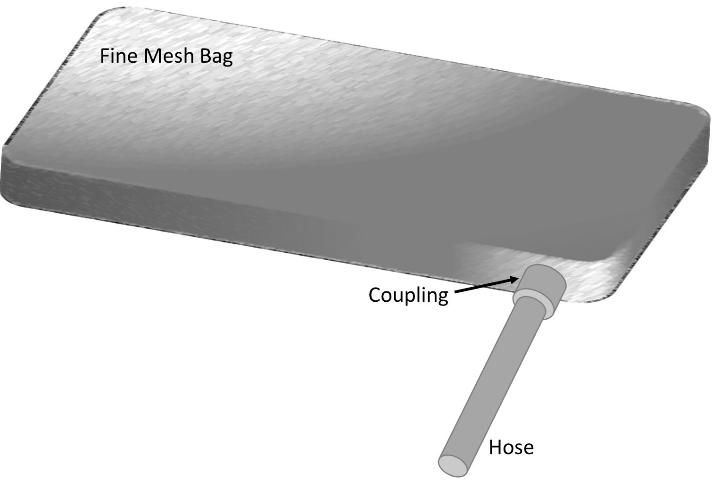

Dead-End Filters

A variety of sock-shaped filters can be used to remove organisms and are also highly effective for the removal of sediments and particulate wastes. Mesh filter socks are typically placed on the end of pipes. They are inexpensive and highly effective. Geotextile filter bags are another solution that can be used to handle direct discharge from hoses (Figure 3). These structures are large, fine-mesh, bagged filters that trap organisms and even fine sediment. Because they are dead-end structures, the bags can also be prone to rupture under high pressure. Filters, mesh socks, and bags make up for in improved escape prevention, but they are also difficult to maintain and clean. These types of filters may be appropriate when used with species of elevated concern (conditional species; for more information, see https://myfwc.com/wildlifehabitats/nonnatives/regulations/).

Credit: UF/IFAS Extension

Covers

Covers, whether composed of netting or plastic film, have two purposes. First, plastic covers and netting can be used on ponds to prevent birds from carrying off non-native species (Figure 4). Pond covers also have an added benefit in reducing losses to birds, which can lead to greater production in outdoor ponds. While infrequent, bird carry-off may be most important for preventing the loss of valuable brood stock. Covers can also be used to prevent fish from leaping out of vats and aquaria (Figure 5) and escaping through trench drains in packing houses and greenhouses. Not all species will require covers, but some species will readily jump. For example, many livebearers will attempt to swim up or jump into water inflows. Pond and tank covers also are required for small sturgeon (< 4lb.; FDACS 2015, pp. 43–44).

Credit: UF/IFAS Extension

Credit: UF/IFAS Extension

Riser-Board Control Structure

A riser-board control structure, also called a flash-board riser, is a common feature on many aquaculture facilities in Florida (Figure 6). Typically used to capture sediment and aquaculture wastes, these structures are essential at some facilities in maintaining compliance with effluent provisions of the Florida Aquaculture BMPs. The design is quite simple. These structures are typically composed of a section of galvanized steel pipe or a more expensive concrete structure with wooden or metal slats stacked vertically to control effluent release. These structures can be placed within ditches at discharge locations where they capture sand and sediment, which can then be used to build up pond banks.

Credit: UF/IFAS Extension

While effective at preventing sediment release, riser-board control structures may not be very effective at preventing the escape of certain kinds of fish, especially small fish or fish that remain near the surface such as many livebearers. Therefore, additional screening upstream or downstream may be necessary. Another problem with these structures is the inevitable pooling of water at the outfall of the structure, which can then serve as a refuge for non-native species. Additional guidance in the design and construction of riser-board control structures is provided by Wilson et al. (2012).

Trickle-Flow Control Structure

Trickle-flow structures are designed to control the flow of water and are superficially similar to riser board structures, having many of the same advantages and disadvantages. They differ in that trickle-flow structures are used in outdoor ponds to control the water level and freeboard and riser board structures are used in drainage ditches (Hill and Ohs 2015). These structures use a standpipe in a pond, which serves as a spillway. They are most useful in maintaining freeboard.

They are particularly effective at handling excessive rain and preventing pond flooding and eventual fish escape. These structures are best paired with detention, retention, and recapture ponds discussed below. The key point in considering this kind of structure is that moderating, slowing, and reducing the discharge of water will improve non-native species containment. Because the design of these structures can be complex, Hill and Ohs (2015) offer relevant guidance.

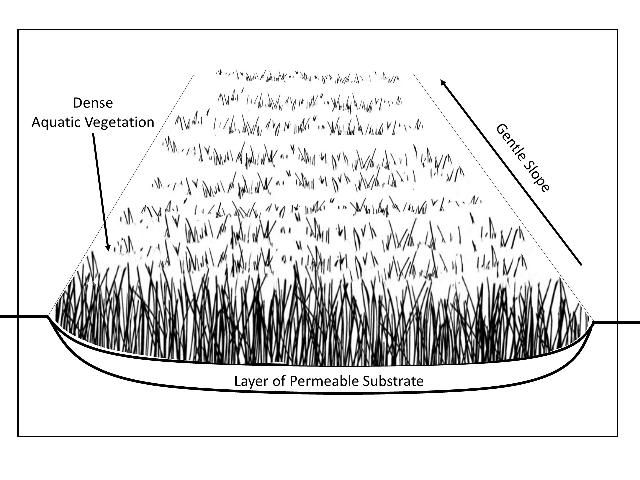

Vegetated Swale

Vegetated swales are wide, gently sloping, densely vegetated channels that slow the flow of water, trap sediments, and process aquaculture effluents, especially nitrogenous wastes (Figure 7). These structures are used when gentle slopes are present along with the typical sandy soils found in Florida. When proper space is available, vegetated swales can be particularly effective in the replacement of ditches before they discharge effluent off-site. Benefits include ease of design and maintenance, greater sediment capture and nutrient processing, and reduced discharge.

Credit: UF/IFAS Extension

Vegetated swales require more space than typical drainage ditches and are impractical at sites with steep surface slopes, impermeable soil, or high discharge. While highly effective at slowing discharge and associated sediment and nutrients, it is not currently documented whether vegetated swales also serve as a barrier to fish escape. However, if swales are heavily vegetated, which presents obstacles to fish movement, and are temporary in nature (i.e., dry up), these structures might also be effective in reducing escape. Guidance in design and construction of vegetated swales can be obtained through the United States Environmental Protection Agency (EPA 1999).

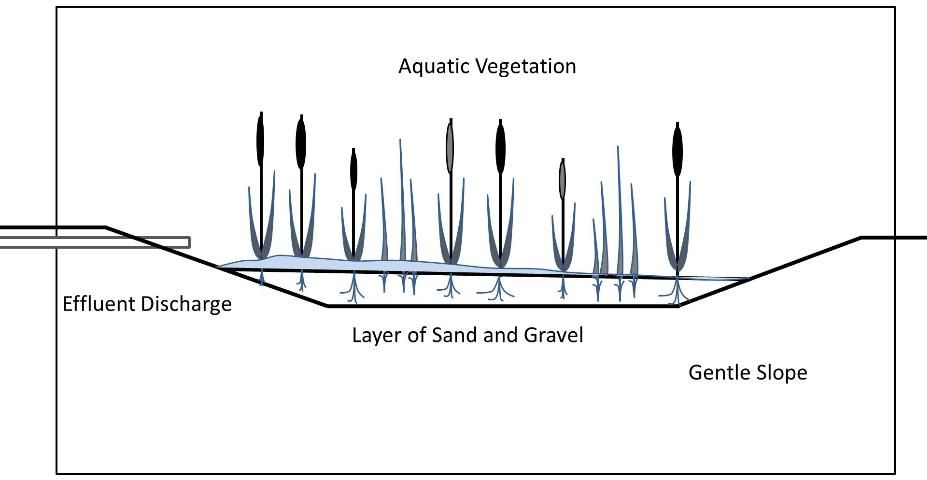

Constructed Wetland

Constructed wetlands are shallow, heavily vegetated basins most typically used in the treatment of urban and row-crop agriculture runoff (Figure 8). They have also been recommended for aquaculture, especially in large production systems such as catfish, shrimp, and tilapia. Constructed wetlands act as large biofilters that remove nitrogenous wastes and also sequester phosphorus in vegetation and sediments. Further, if they dry up periodically, these structures are effective at minimizing the escape of non-native species. However, without water-control structures (e.g., trickle-flow), water levels within the wetland will be variable, dictated by rainfall, discharge from greenhouses, and the pumping of ponds, which might limit the establishment of wetland plants.

Credit: UF/IFAS Extension

Once created, wetlands can be a low-cost way of treating effluents. However, these structures are not without their drawbacks. Constructed wetlands will require more acreage than other solutions such as vegetated swales, and the initial investment in time and expense can be prohibitive. Ultimately, designs with non-permanent water are advantageous for both the vegetated swale and the constructed wetland if preventing non-native fish escape is a primary goal. Drying will prevent the persistence of most non-native species in these structures.

Recapture Pond

A recapture pond is a small, shallow impoundment (~200 ft2) used to receive relatively particulate- and sediment-free discharge from packing houses. During the packing and sorting process, fish are sometimes mishandled and can make their way to the trench drain of the packing house or other greenhouse/building. The mishandling of fish is not uncommon and a variety of fish can be found in the trench drains of aquaculture facilities. If the recommended control structures—screens and detention pond and so on—have failed or are not in place down the line, fish escape from a packing facility can be a serious issue, especially in comparison to the rate fish may escape during other phases of harvest and distribution. For example, it is thought, but not verified, that relatively few fish survive passage through a pump during the drawdown process (depending on pump type). Despite the best efforts of operators, however, fish can sometimes escape. Thus, recapture ponds with appropriate structures in place (a trickle-flow structure with screens is best) can then be used to fill orders in the event fish stocks in holding tanks are depleted.

Detention and Retention Pond

Generally speaking, detention and retention ponds will increase the residence time of water on aquaculture facilities, allowing time for biological processing of wastes and predation of non-native fish that might otherwise escape by native fishes (Figure 9). These structures differ in that retention ponds are designed to hold water without a fixed release point; instead, water percolates through the pond bottom/embankment or evaporates. In contrast, detention ponds will eventually discharge water off-site. Detention and retention ponds have many benefits. These can include a reduction in waste material leaving the facility (Shireman and Cichra 1994), increased sediment capture on-site (sediments might then be used to build berms and pond banks), fewer BMP compliance issues (Tuckett et al. 2016c), and a reduction in non-native fish escape (Tuckett et al. 2014). When planning or using a detention or retention pond to prevent the escape of non-native species, consider the following issues:

- water-storage capacity

- stocking of native fish predators

- pond maintenance

Credit: UF/IFAS Extension

Water-Storage Capacity

For the processing of waste and removal of non-native species that slip through other containment barriers, the most important aspect is residence time, which is the amount of time it takes for water to move through the detention pond. To increase the effectiveness of detention ponds, the pond size should be based on the volume of expected facility discharge. While residence time is important, flooding can also be an issue. For all settling basins, proper water storage capacity should be maintained and trickle flow control structures described above work well in managing freeboard. Hill and Ohs provide guidance on the proper design and size of detention ponds according to specific facility characteristics (2015).

Native Fish Predators

The effectiveness of detention ponds in preventing the escape of non-native species can be increased if the ponds are stocked with native predators such as largemouth bass Micropterus salmoides, bluegill Lepomis macrochirus, and eastern mosquitofish Gambusia holbrooki. Research at the UF/IFAS Tropical Aquaculture Laboratory (TAL) showed that these predatory species readily consume adults and juveniles of ornamental fish, greatly reducing the ability of these non-natives to establish populations. These native species are available for purchase from aquaculture facilities in Florida. Fewer restrictions are in place for the stocking of bluegill and eastern mosquitofish; however, only the Florida subspecies of largemouth bass (Micropterus salmoides floridanus) is legal to stock in facilities south and east of the Suwannee River. However, regulations pertaining to largemouth bass stocking in Florida can change. Always check with the Florida Fish and Wildlife Conservation Commission for current regulations (https://myfwc.com).

Pond Maintenance

Detention and retention ponds are not without their drawbacks. These ponds require a high initial investment to create and are also costly to maintain. A recent reclamation (2014) of a detention pond at an aquaculture facility in Florida cost ~$20,000 to remove deposited sediments. If the pond receives sediment-laden water, its effectiveness can be compromised, especially if vegetated islands form and provide refuges for non-native species. Ultimately, these structures are not possible at every facility because of their size and also because they will reduce available acreage that could be devoted to production ponds. Like other structures, an important consideration is the cost-benefit of their installation and use.

Indoor Recirculating System

Recirculating systems filter water with the aid of an appropriate biofilter (and also non-biological filter) so that water can be reused (Figure 10). Recirculating systems drastically reduce the amount of water used and are also very effective at limiting the discharge of waste and the escape of non-native species. Once again, any practice that limits the amount of water leaving as effluent will also assist in preventing fish escape. Recirculating systems may be most important for conditional species (FDACS 2015, p. 26–28). They may also be necessary for the production of marine fish due to the expense associated with maintaining salinity and the zero discharge provisions for saltwater found in Florida Aquaculture BMPs. While these structures have many clear benefits, they are often impractical for the culture of many species in Florida because of the added production cost. Instead, these systems are often used to hold stock prior to sale.

Credit: UF/IFAS Extension

Zero Discharge

Zero discharge is an ideal means of preventing, perhaps eliminating, environmental issues that stem from intensive aquaculture production. To achieve zero discharge, facilities use a combination of indoor recirculating systems and take advantage of permeable soils. However, zero discharge is most often found at the marine production facilities because Florida Aquaculture BMPs state that "Saline water shall not be discharged to freshwater environments" (FDACS 2015, p. 10). Ultimately, for the vast majority of production facilities, zero discharge may be impossible due to location, precipitation, and expense.

Fencing

Theft and facility vandalism have occurred at aquaculture facilities in Florida. To minimize these issues, fencing and other security structures (lighting, etc.) can be used to restrict public access (Figure 11). Security provisions to prevent theft are not optional for the rearing of conditional species according to Aquaculture BMPs.

Credit: UF/IFAS Extension

One Final Note

The most effective and realistic strategy for preventing the escape of non-native species will vary among facilities. In general, however, the routing of surface water to detention or retention ponds is the most effective strategy for limiting escape and also for pollution control. Some of these structures, the detention pond, for example, will serve double duty in that they are useful in preventing sediment release and also limit fish escape. However, it cannot be assumed that structures that work for sediment will also prevent fish escape. FDACS inspectors place emphasis on effluent treatment provisions of the Aquaculture BMPs; be aware of the potential tradeoffs between prevention of wastes or sediments leaving the farm in effluents and the prevention of escape.

No single barrier will be 100% effective, and structural redundancy is the key to preventing the release of non-native organisms. Aquaculture BMPs for Florida are outcome-based (no fish off site). This outcome-based approach places the burden of selecting the most appropriate escape strategies solely in the hands of the aquaculture producer; however, a facility that uses screens on all holding systems, pumps, and pipes; control structures at discharge points; and a water-treatment structure (swale, wetland, pond) will often meet BMP standards. While producers are solely responsible for preventing the escape of non-native species, consultation with FDACS inspectors can help determine the most appropriate structural strategies for your facility. Extension faculty and staff at the UF/IFAS TAL in Ruskin can also assist producers regarding structural features and strategies designed to prevent escape.

Acknowledgements

First and foremost, we thank our aquaculture facility cooperators and the Florida Tropical Fish Farms Association. This research would not have been possible without their generous support. We are indebted to staff at the Florida Department of Agriculture and Consumer Services Division of Aquaculture, including Joe Clayton, Kal Knickerbocker, Serina Rocco, Portia Sapp and Paul Zajicek. Funding was provided by the UF/IFAS School of Forest Resources and Conservation, the UF/IFAS Tropical Aquaculture Laboratory (Craig Watson, director), and a grant from the Florida Department of Agriculture and Consumer Services' Division of Aquaculture.

References

EPA. 1999. Storm Water Technology Fact Sheet Sand Filters. U.S. Environmental Protection Agency, Office of Water, Washington D.C.

FDACS. 2015. Aquaculture Best Management Practices Rule. Florida Department of Agriculture and Consumer Services, Division of Aquaculture, Tallahassee, FL.

Hill, J. E., Q. M. Tuckett, C. V. Martinez, J. L. Ritch, and K. M. Lawson. 2016. Preventing escape of non-native species from aquaculture facilities in Florida, part 2: facility evaluation strategies. FA196. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa196

Hill, J.E., and C.L. Ohs. 2015. Stormwater Detention and Discharge from Aquaculture Ponds in Florida. Gainesville: University of Florida Institute of Food and Agricultural Sciences. BUL334. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa158.

Shireman, J. V., and C. E. Cichra. 1994. "Evaluation of aquaculture effluents." Aquaculture 123:55–68.

Wilson, C., L. Scotto, B. Boman, and T. Gaver. 2012. Flatwoods Citrus Best Management Practice?: Riser-Board Structures. SL-196. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/ss409.

Tuckett, Q. M., C. V. Martinez, J. L. Ritch, K. M. Lawson, and J. E. Hill. 2016a. Preventing escape of non-native species from aquaculture facilities in Florida, part 1: general considerations and regulations. FA195.Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa195.

Tuckett, Q. M., C. V. Martinez, J. L. Ritch, K. M. Lawson, and J. E. Hill. 2016b. Preventing escape of non-native species from aquaculture facilities in Florida, part 4: operational strategies. FA198. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa198.

Tuckett, Q. M., J. L. Ritch, K. M. Lawson, and J. E. Hill. 2014. Best management practices and escapement of non-native fish from aquaculture facilities in Florida. Final Report. Florida Department of Agriculture and Consumer Services. Tallahassee, Florida.

Tuckett, Q. M., J. L. Ritch, K. M. Lawson, and J. E. Hill. 2016c. "Implementation and Enforcement of Best Management Practices for Florida Ornamental Aquaculture with an Emphasis on Nonnative Species." North American Journal of Aquaculture 78:113–124.

Appendix

Availability of aquaculture netting and mesh. Inclusion or mention of a product or business in appendix 1 or elsewhere does not indicate endorsement by UF/IFAS or the authors.

Industrial coarse mesh (typically polyethylene) is available through the Florida Tropical Fish Farms Association Co-Op Store (https://www.ftffacoop.com/) and varies between half to one inch. Additional sizes and larger quantities can also be found through industrial mesh providers (Industrial Netting; industrialnetting.com).

The various structures used by aquaculture facilities in Florida to prevent the release of aquaculture wastes and the escape of non-native species. Structures are also qualitatively scored for their ability to control escape (X = low control; XXX = high control). Estimated costs ($ = cheapest; $$$$ = most expensive) are also included. For the estimated cost of detention and retention ponds (**), existing structures can lower the cost.