Introduction

When strategies to prevent the escape of non-native species from aquaculture facilities are considered, it is usually structural strategies, discussed in Part 3 of this series, that receive the most attention. The emphasis on structures makes sense because many of these structures (e.g., detention ponds and swales) have numerous environmental benefits (Shireman and Cichra 1994). Further, research at the UF/IFAS Tropical Aquaculture Laboratory has shown that structural strategies also reduce non-compliance with Florida Department of Agriculture and Consumer Services (FDACS) Best Management Practices (BMPs) (FDACS 2015; Tuckett et al. 2014). On the other hand, the operational strategies discussed in this article, the management of water, facilities, and employees, must not be overlooked. Operational strategies are easy, inexpensive, and, when used alongside structural strategies, highly effective, offering an impressive return on a minimal investment in the overall effort to minimize the escape of non-native species.

This document is the fourth in a four-part series devoted to educating industry and other stakeholders on the importance of preventing escape of non-native species from aquaculture facilities as well as strategies for non-native species containment and regulatory compliance (Tuckett et al. 2016a; Hill et al. 2016; Tuckett et al. 2016b).

Series Contents

- Part 1: General Considerations and Regulations—introduces series, explains why non-native species containment is important, provides information on regulations, including the Florida Aquaculture Best Management Practices (BMPs) rule, describes the BMP inspection process, and provides advice on achieving compliance

- Part 2: Facility Evaluation Strategies—describes farm layouts, how fish escape, and a process that aquaculturists can complete to identify potential escape points on their farms

- Part 3: Structural Strategies—provides information on structures and barriers that can prevent escape

- Part 4: Operational Strategies—describes operational and management strategies to prevent escape

Operational Strategies

Operational strategies aimed at controlling the escape of non-native species and associated aquaculture wastes involve the management of water, facilities, and employees. Compared to structural strategies, operational strategies may be easier and more cost-effective to implement; however, they are not without their own challenges. Aquaculture facilities, like any other business, can experience employee and facility management issues. For aquaculture activities, this can result in the escape of non-native species. Some of these problems might include:

- failure to manage water flowing into/out of the facility during inevitable natural variation in precipitation, especially flood events

- failure to maintain control structures

- operator error

- employee behavior problems such as unreliability or inconsistency in following BMPs

- lack of flexibility in responding to changes

Operational strategies to minimize escape and overcome water management, facility, and employee issues include:

- Water use reduction

- Maintenance of appropriate water levels in ditches and ponds

- Discharge management and reduction

- Aquaculture effluent treatment

- Facility inspection and maintenance

- Employee management/training

Water Usage

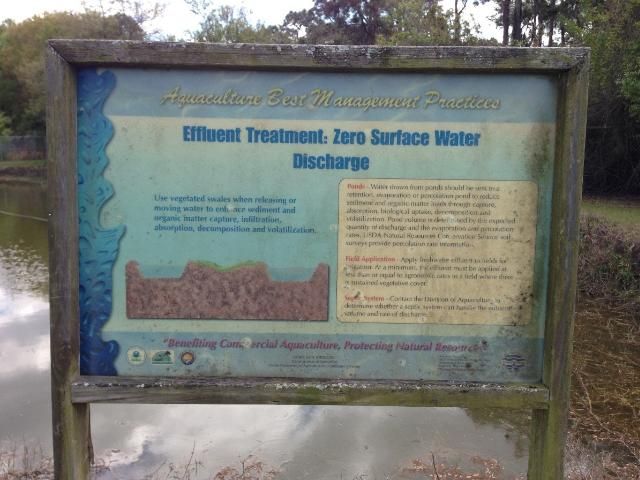

Many of the environmental concerns about commercial aquaculture are related to water resources. Avoiding excessive discharge is one of the most effective ways to reduce the environmental impacts of aquaculture production. Zero-discharge facilities virtually eliminate the escape of non-native species and also the export of aquaculture wastes.

FDACS exempts zero-discharge facilities, also called minimal-impact facilities, from following BMP rules for effluent treatment. Minimal-impact facilities are exempt because they do not discharge outside the facility and therefore do not affect waters of the state (FDACS 2015). For zero-discharge facilities, few pathways remain for the escape of non-native species. For most aquaculture facilities in Florida, however, zero discharge is impossible due to a variety of factors related to economics, geography, and hydrology.

Producers can reduce water use and resulting effluent by eliminating water flow to empty vats or aquaria, consolidating stock into a smaller number of vats or aquaria (if feasible), and increasing the use of recirculating systems (if feasible). Although recirculating systems have a number of benefits in water use and discharge, they can be capital- and labor-intensive and may not be suitable for production of some species. Reductions in water usage in winter, especially for packing houses and greenhouses that discharge warm water year-round, may reduce the ability of cold-sensitive non-native species to persist in effluents on- or off-site.

Water-Level Management

Effective water-level management can reduce effluent volume, which is related to the water budget of an aquaculture facility, and, ultimately, to the inflow and outflow of water to and from the facility. Inflows include water usage (discussed above), retention of water from aquaculture activities, and precipitation. Outflows include seepage through ponds and ditches, evaporation, overflow from ponds (flooding), and discharge of effluents.

A goal in managing water levels on aquaculture facilities is to reduce the deliberate and accidental discharge of effluents because effluents are the dominant pathway for the escape of non-native species.

Extra water-storage capacity in ponds is useful to prevent pond overflow and accidental discharge resulting from heavy rains. Overflow may release cultured fishes from the ponds, especially top-water species (e.g., livebearers), and may also lead to contamination of production ponds by pest species such as walking catfish. Storage capacity is maintained by avoiding excessive filling of ponds, especially during the wet season. When filling ponds, operators should not fill them completely. If needed, facility operators can apply active management such as pond drawdowns. FDACS recommends a minimum of one foot freeboard, but more should be given if operators expect large amounts of rainfall.

In addition to the water-level management of ponds, the water level of interior ditches should also be managed. Ditches that lack scour holes and have a gentle slope are best for periodic drying, which is important because ditches that dry periodically improve non-native species containment. Ditches that do not hold water permanently will prevent the establishment of non-native fishes on-site, especially the livebearers, which readily reproduce in ditch environments. Overflow of ponds and ditches should be avoided by actively pumping ponds to maintain freeboard and managing the pumping rate so as not to exceed the capacity of the ditch. This will be especially important for those ponds and ditches near the property boundary.

Effluent Treatment

Before effluents leave an aquaculture facility, they can be chemically treated to eliminate non-native species. However, this is seldom if ever done in commercial aquaculture settings. In general, the use of chemical treatments is cost-prohibitive due to the large effluent volume that is discharged from many commercial aquaculture facilities in Florida and the potential need to clean up chemical residues before discharge. Chemical treatments do have their uses, including Antimycin-A (fish toxicant), Bayluscide® (molluscicide), chlorine bleach (sterilant; fish toxicant; molluscicide), and rotenone (fish toxicant). Bayluscide and chlorine bleach are effective on invertebrate non-native species such as snails. Chlorine, in particular, is an effective and inexpensive molluscicide typically on-hand at many aquaculture facilities. Some chlorine bleach products may be used as a fish toxicant, especially in ponds, where chlorine bleach also serves to sterilize the remaining water and sediments for later restocking. Rotenone, a broad-based fish toxicant, can also be used if water does not leave the property. For rotenone, an applicator's license and training is required, and this training is routinely available at the University of Florida, Tropical Aquaculture Laboratory (Ruskin, FL). Cichra (2015) provides guidance on the application of emulsified or powdered rotenone to non-flowing surface waters. Finlayson et al. (2010) provide a recent, detailed discussion of the use of rotenone as a fish toxicant in the United States.

Most chemicals would be used as a batch treatment, wherein effluents are held, treated, then detoxified using specific chemicals (e.g., potassium permanganate for rotenone) before effluent waters are released. From a practical standpoint, chemical treatments are generally least expensive and most effective at killing target organisms when they are used in culture systems, such as tanks or ponds, rather than in the effluent stream. Batch treating ponds and tanks rather than the effluent stream will ensure that no living non-native that might escape to the effluent or become a pest/contaminant in subsequent production cycles remains in the systems.

Discharge Management

Pond draining contributes disproportionately to the annual discharge from aquaculture facilities, can result in the escape of non-native species, and can be reduced or avoided as circumstances allow. Effluent discharge can be managed using a comprehensive approach, one that eliminates unnecessary release and reuses water when possible. Reducing pumping or draining of ponds also can save producers time and money. Strategies to manage discharge to prevent the escape of non-native species can include:

- Reducing water use (discussed above)

- Preparing for periods of high precipitation

- Pumping effluents to rip-rap

- Pumping pond water to adjacent ponds

- Reducing pond pumping and washing

When water must be discharged, as during the pumping of ponds to concentrate fish for harvest, and to maintain freeboard in preparation for high precipitation, FDACS mandates that the location of the discharge point for pumped effluent must be oriented at least 100 feet upstream from a control structure (FDACS 2015) (Figure 1). Pumping pond effluents over rip-rap such as gravels and cinderblocks can prevent scour hole formation and may trap non-native species that have survived passage through the pump. Keep plunge heights of discharge hoses as low as possible to prevent pools from forming in ditches. These pools, called scour pools, can create permanent or semi-permanent habitat for non-native species. If more than one pond is to be pumped in a single day, operators can pump water into previously drained ponds during the initial drawdown process, taking care not to erode pond banks. This practice is highly effective at minimizing the escape of non-native species. Effluent may be used to irrigate terrestrial crops, provided the effluent does not contain chemicals and is applied away from surface drainage. Facility operators can also increase the interval between pond drawdowns or reduce the frequency of pond washing after harvests as allowed by production schedules.

Credit: UF/IFAS Extension

Many BMP discharge management provisions are designed to increase the residence time of sediment-laden water. Retaining the water longer allows particulates to settle and remain on the facility. While effective at settling sediments and particulate organic matter, residence time and greater settling may not be sufficient to prevent the escape of non-native species. Facility operators should also use screens on the pump intake hose and at other locations on the facility (Figure 2) as discussed in Tuckett et al. (2016b).

Credit: UF/IFAS Extension

Facility Maintenance

Water-control structure failure is a commonly seen BMP non-compliance issue (Tuckett et al. 2016c), and the maintenance of water-control barriers (see Part 3 in this series) is one of the most effective ways to maintain BMP compliance for sediment discharge while also ensuring non-native species are retained on-site. FDACS inspectors will most often note the state of maintenance on ditches, control structures, pond berms near the property boundary, and detention ponds. Maintenance of these structures should be one part in a larger program devoted to managing the escape of non-native species.

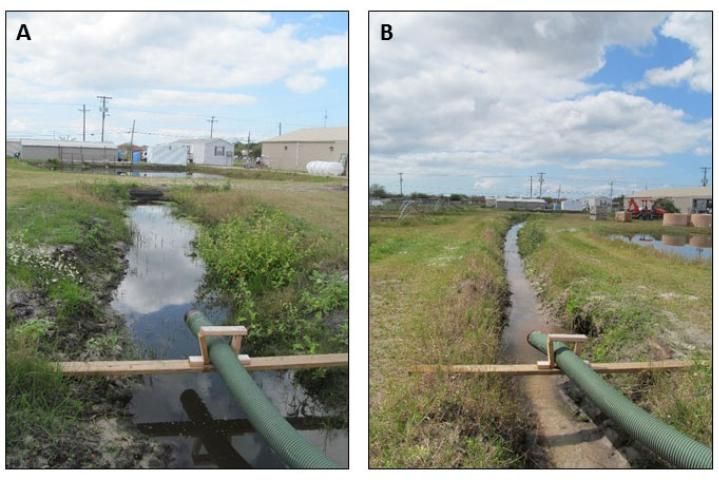

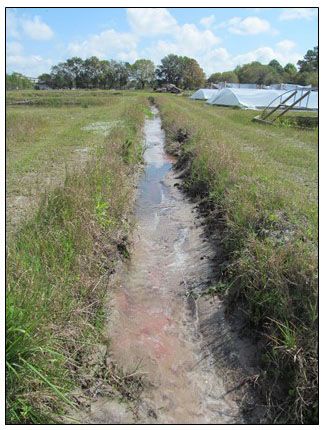

Ditches

FDACS inspects and routinely revisits aquaculture facilities if ditches are not properly maintained (Tuckett et al. 2016c). Problems in ditches are most often caused by the accumulation of sediment, which reduces the residence time of the water and effluent in the ditch and the deposition and ultimate capture of particulates (Figure 3). With respect to non-native species, the maintenance of ditch berms along the property boundary is important for providing separation between the facility and the broader environment. Eliminating scour holes and uneven ditch slopes is key, since, as discussed previously, scour holes and uneven slopes will allow water to pool and provide habitat for non-native species. Vegetation removal allows FDACS inspectors to view water control structures and the amount of sediments within ditches. Ultimately, operators need to weigh the benefits of increased residence time versus periodic drying, which will prevent the establishment of non-native species.

Credit: UF/IFAS Extension

Control Structures

Another among BMP noncompliance issues often-cited by FDACS inspectors is the non-functioning control structure. Like poorly maintained ditches, control structures that fail will typically result in a revisit from the inspector. One of the most common problems is the flow of water around or underneath the structure, which readily permits the escape of both non-native species and aquaculture wastes. Routine inspection is the key, especially at times of high discharge. When problems are discovered, fill (e.g., earth or sandbags) can be used to reroute water over the control structure.

Boundary Berms and Pond Banks

Boundary berms and pond banks can sometimes fail during floods and lead to the rapid discharge of non-native species and aquaculture wastes into the environment; this is especially true of berms and banks that are located near the property boundary. When conditional (restricted) species are held, the maintenance of boundary berms is especially important. Pond berms should be maintained to prevent gullying and sloughing, which leads to failure. Water level in ponds should also be maintained throughout the year, even if the production pond is empty, because empty ponds can be prone to sloughing. However, ponds can be left empty for short periods of time if operators intend to capture pumped effluents.

During construction and maintenance projects where bare ground is exposed, operators can employ a site reclamation and revegetation plan to quickly minimize erosion and damage to ponds, berms, and ditches. Mulching (e.g., straw or wood chips) can be utilized on reseeded areas to reduce splash erosion, accumulate sediment, slow runoff, minimize gullying of ponds/berms, and also assist in the germination and development of vegetation. Well-vegetated banks are less prone to failure because grass and other vegetation provides protection against erosion. However, trees and large bushes growing on pond berms can compromise berm integrity. Excessive use of herbicides on pond banks and berms promotes erosion. If ponds are in need of renovation, these ponds should be dug deeper to increase their water storage capacity and also reduce the risk of flooding and ultimately failure. The removed earth can then be used to repair interior ponds with degraded banks and to build up pond edges and levees to provide separation between the aquaculture facility and the surrounding environment.

Building up pond berms and ditches near the property boundary will provide additional benefits, including the prevention of on-farm establishment of non-native species from outside the farm. Species that will readily establish on aquaculture facilities from surrounding waters can include the brown hoplo Hoplosternum littorale, Asian swamp eel Monopterus albus, and walking catfish Clarias batrachus.

Detention/Retention Ponds

Detention ponds are one of the most effective structures that are used on aquaculture facilities to limit the escape of non-native species in aquaculture effluent (Tuckett et al. 2014) (discussed in Part 3). True retention ponds prevent discharge of effluent and are highly effective at non-native species containment. Stocking native predatory fishes such as largemouth bass Micropterus salmoides and eastern mosquitofish Gambusia holbrooki can increase the effectiveness of detention ponds by eliminating non-natives before they have a chance to escape via the effluent.

Detention ponds must be maintained adequately, however, to do their job effectively. For example, pumping production ponds can fill detention ponds with sediment, especially if control structures are not in place. Sediment accumulation will reduce detention pond depth and increase establishment of vegetation, which will provide harborages for non-native species that settle there, in some cases allowing them to survive and multiply. Shallow detention ponds will also limit access of large-bodied predators such as largemouth bass to any non-native fish that accesses the pond. Further, detention ponds can also harbor non-native species such as tilapia, Asian swamp eel, brown hoplo, and walking catfish that may invade production ponds; in cases where the problem is severe, pond treatment with rotenone might be necessary. A routine maintenance program will help ensure that issues do not arise.

Employee Management

Employees are authorized representatives of the facility operator, making it the employers' responsibility to prevent environmental issues caused by their employees. This responsibility stems from common law doctrine where negligent actions by employees that lead to environmental problems or the failure of employees to implement and follow BMP rules will lead to non-compliance issues. In such cases, FDACS cites the employer, not the employee.

To address these issues, facility operators should properly train all employees in the requirements and guidelines for non-native species containment found in the aquaculture BMPs. These guidelines, especially those pertaining to the pumping of ponds (100 feet upstream from a control structure), maintenance of freeboard (1 foot), and escape of fish (none), could be posted at the facility, removing any reasonable deniability on the part of the employees (Figure 4). Employers should make willingness to follow aquaculture BMPs a condition of employment and dismiss any employee who is unwilling to comply with the BMPs. With proper training and periodic employee review, it becomes the responsibility of both the employer and employee to ensure BMPs are followed and the escape of non-native species is minimized. Staff at the UF/IFAS Tropical Aquaculture Laboratory can assist with farm owner/staff training in non-native species BMP compliance.

Credit: UF/IFAS Extension

Routine Inspections

While FDACS conducts mandatory inspections of certified aquaculture facilities, and most facilities are visited twice yearly (Tuckett et al. 2016c), facility operators can also conduct their own routine inspections. These routine inspections and reevaluations should scout for problems that might arise due to water management, facility, and employee issues discussed above, as well as potential problems with the structural barriers discussed in Part 3 (Tuckett et al. 2016b). Inspection of effluents on-site and also adjacent off-site ditches and streams for non-native species will reveal the actual effectiveness of both the operational and structural strategies. The establishment and posting of accurate maintenance and inspection logs will allow operators to efficiently manage their operations.

Other Strategies

Additional strategies beyond those listed here can also be used to manage employees, maintain structures, and treat effluents. It is ultimately up to the facility operator to determine the most appropriate strategies to implement. Operators should always be looking for better strategies so that non-native species can be retained on-site and environmental concerns can be minimized.

Acknowledgements

First and foremost, we thank our aquaculture facility cooperators and the Florida Tropical Fish Farms Association. This research would not have been possible without their generous support. We are indebted to staff at the Florida Department of Agriculture and Consumer Services Division of Aquaculture, including Joe Clayton, Kal Knickerbocker, Serina Rocco, Portia Sapp and Paul Zajicek. Funding was provided by the UF/IFAS School of Forest Resources and Conservation, the UF/IFAS Tropical Aquaculture Laboratory (Craig Watson, director) and a grant from the Florida Department of Agriculture and Consumer Services' Division of Aquaculture.

References

Cichra, C. E. 2015. Managing Florida ponds for fishing. CIR-802. University of Florida IFAS Extension, Circular 802.

FDACS. 2015. Aquaculture Best Management Practices Rule. Florida Department of Agriculture and Consumer Services, Division of Aquaculture, Tallahassee, FL.

Finlayson, B. J., R. Schnick, D. Skaar, J. Anderson, L. Demong, D. Duffield, W. Horton, and J. Steinkjer. 2010. Planning and Standard Operating Procedures for the Use of Rotenone in Fish Management; Rotenone SOP Manual. American Fisheries Society, Bethesda, Maryland.

Hill, J. E., Q. M. Tuckett, C. V. Martinez, J. L. Ritch, and K. M. Lawson. 2016. Preventing escape of non-native species from aquaculture facilities in Florida, part 2: facility evaluation strategies. FA196. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa196.

Shireman, J. V., and C. E. Cichra. 1994. "Evaluation of aquaculture effluents." Aquaculture 123:55–68.

Tuckett, Q. M., C. V. Martinez, J. L. Ritch, K. M. Lawson, and J. E. Hill. 2016a. Preventing escape of non-native species from aquaculture facilities in Florida, part 1: general considerations and regulations. FA195. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa195.

Tuckett, Q. M., C. V. Martinez, J. L. Ritch, K. M. Lawson, and J. E. Hill. 2016b. Preventing escape of non-native species from aquaculture facilities in Florida, part 3: structural strategies. FA197. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/fa197.

Tuckett, Q. M., J. L. Ritch, K. M. Lawson, and J. E. Hill. 2014. Best management practices and escapement of non-native fish from aquaculture facilities in Florida. Final Report. Florida Department of Agriculture and Consumer Services. Tallahassee, Florida.

Tuckett, Q. M., J. L. Ritch, K. M. Lawson, and J. E. Hill. 2016c. "Implementation and Enforcement of Best Management Practices for Florida Ornamental Aquaculture with an Emphasis on Nonnative Species." North American Journal of Aquaculture 78:113–124.