This work was supported by the USDA National Institute of Food and Agriculture, Specialty Crops Research Initiative, project award no. 2019-70016-29096, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture, and the Multi-State Hatch FL-SWF-005724, “Economic Valuation and Management of Natural Resources on Public and Private Lands (W5133).” Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.

This publication provides per-tree and per-acre costs of adopting oxytetracycline (OTC) trunk injections for large-scale orange production in southwest Florida. The values represent the costs observed by early adopters (i.e., the 2023–24 season). Note that this is a new practice in citrus production, so we expect costs to decrease over time as the technology improves, others enter the market, crews become more efficient at application, and adoption becomes more widespread. This information will be helpful to citrus growers, Extension agents, and other citrus industry stakeholders interested in understanding the costs of trunk injection and OTC applications in tree crop production. The values shared are estimates; costs will vary depending on the operation’s application methods, products used, tree density, and other grove characteristics.

Introduction

Citrus is one of the most important agricultural products in Florida. The citrus industry supported over 32,000 jobs and had a total economic impact of over $6.9 billion in 2020–21 (Cruz et al. 2023). Florida produced over 73% of the total oranges in the United States in 2005–06 (USDA NASS 2023b). However, acreage, yield, and the total value of production have consistently fallen since 2005, when Huanglongbing (HLB, a.k.a. citrus greening) was first detected in the state. The total on-tree value of orange production in 2021–22 was $422.65 million, 32% of the total production value in 2006–07 (USDA NASS 2024; USDA NASS 2023b). Hurricane Ian affected most major citrus production regions in 2022, further decimating the industry. As a result, the on-tree value of the total citrus crop for the 2022–23 season dropped by 61% from the 2021–22 season. Production is down to 18 million boxes compared with more than 45 million boxes in the 2021–22 season (USDA NASS 2023).

HLB is associated with the Candidatus Liberibacter asiaticus (CLas) bacterium, which colonizes the phloem of affected citrus trees. The bacterium is vectored by the Asian citrus psyllid (ACP), first detected in Florida in 1998 (Diepenbrock et al. 2023; Halbert 1998). Insecticide applications do not adequately control the ACP vector or prevent CLas infection. One attempted method for controlling the spread of the bacteria was applying antibiotics through foliar sprays. Three antibiotics, streptomycin, oxytetracycline (OTC), and kasugamycin, are currently registered for use in plant agriculture (Albrecht et al. 2023; Batuman et al. 2024).

A special-use emergency exemption (section 18) was approved by the EPA in 2016, which allowed the foliar use of streptomycin sulfate, oxytetracycline hydrochloride, and oxytetracycline calcium in Florida to suppress CLas. However, these sprays were not effective, most likely because of the phloem-limited, systemic nature of the bacteria.

Trunk injection is an alternative way to deliver pesticides systemically in woody crops (Archer et al. 2021; Archer et al. 2022). In addition to more precise delivery, injecting pesticides is generally safer and more environmentally friendly than applying them by foliar sprays (Wise 2014). Growers expect that OTC injections would increase yield and pound solids (Brix) per box which could increase their revenue by up to 30% (Anonymous grower, interview, May 3, 2023). Trunk injection of OTC is now widely practiced by the Florida citrus industry to control HLB (Giles 2024).

OTC Trunk Injection in Citrus

Trunk injection application involves drilling a small hole in the trunk of a tree to inject pesticides or other materials. This can be done with different types of injection devices (Archer et al. 2021; Berger and Laurent 2019). Research in Florida showed that OTC injections can suppress the HLB-associated bacterium and increase yield and fruit quality (Archer et al. 2022; Archer et al. 2023; Li et al. 2019). Hu et al. (2017) found that OTC and streptomycin injections increased orange tree yields by 19% and Brix by 16%. More recent studies found that OTC injection increased yield in mature Valencia orange trees by 30% to more than 60% (Archer et al. 2023; Albrecht 2023). These studies also found that orange juice Brix consistently increased by 10% to 20% (Albrecht 2023). A 24(c) special local need (SLN) label was approved in October 2022 because of the desperate state of the Florida citrus industry from HLB and the documented positive effects of OTC injections. This allowed citrus growers in Florida to use OTC injections as an additional tool to fight HLB.

Objective

There is increased interest among citrus growers in adopting OTC trunk injections because of its efficacy in controlling HLB. A 2023 survey conducted by Citrus Industry Magazine indicated that more than 84% of respondents from a sample of 89 growers have adopted this technology since the SLN was issued (Giles 2024). However, labor and other costs associated with trunk injections may restrict its use.

Our publication presents the costs of OTC trunk injections in southwest Florida. More specifically, we present two partial budgets for large groves with tree densities of 150 trees/acre and 200 trees/acre. The partial budgets include detailed cost items for an OTC trunk injection operation for citrus trees for orange juice production. We discuss the per-tree and per-acre costs of the operation. We also summarize detailed information on OTC application rates, device use and costs, costs of machinery and equipment, and labor costs. Our cost estimates are most relevant for large citrus growers who plan to inject citrus trees with OTC on their own. We believe that the results from our study will help citrus growers who are new to OTC trunk injections and are planning to implement them in orange production.

Methods and Assumptions

This study presents partial budgets for OTC trunk injection operations in southwest Florida orange production. A partial budget for an agricultural producer estimates the changes in costs and incomes that accrue from adopting a new or additional production practice (Cho et al. 2012), leaving other aspects of production unchanged (Tigner 2018). Therefore, our partial budgets only present the additional costs of adopting OTC trunk injections in orange production. They do not consider benefits such as increased yield and fruit quality that will positively impact revenue. Note that benefits vary depending on factors such as citrus variety, tree age and health, location, and grove management. Benefits also require time to accrue.

We interviewed three large growers (over 1,000 acres) in southwest Florida who applied OTC through trunk injection. These interviews captured their trunk injection practices and approximate costs to implement the technology on a large scale. We collected information about grove operations, cost of production without OTC application, OTC formulation, application rates, and materials, labor, equipment, and fuel costs. OTC injection application methods varied as grove logistics and management strategies varied by operation. Each grower applied OTC at different rates, and their groves differed in tree density. We took the average costs of the three growers, weighted by their tree density, to provide the approximate costs of using trunk injections for OTC application.

Participating growers primarily injected Valencia and some Hamlin orange trees in their groves. OTC was injected in HLB-affected trees at least 180 days before harvesting, as the label instructs. Groves were irrigated the night before the injections. Trees of fruit-bearing age were injected once a year, while those of non-bearing age were injected twice a year. We developed two partial budgets with this information for mature trees that were injected once annually for groves with densities of 150 trees/acre and 200 trees/acre. The primary cost categories in our partial budgets are chemical, injection devices, machinery, equipment, fuel, and labor. Key assumptions, application rates, and costs are summarized below.

- Chemical costs:

i. All three growers used an OTC formulation of 95% OTC hydrochloride. The cost for the formulation was obtained from local distributors and was priced at $291.50 for a 2.75 lb bag. We use a price of $106/lb for our calculations.

ii. The label recommends using the chemical at a concentration of 11,000 ppm for bearing citrus trees with good health (>75% leaf canopy) or 5,500 ppm for bearing citrus trees with poor health (≤75% leaf canopy). Participating growers mentioned that groves are not homogeneous in terms of tree health, thus the applied OTC concentration will vary by grove. We base our OTC concentration calculations on 8,250 ppm or 8.25 mg/mL solution, the average of 11,000 ppm and 5,500 ppm.

iii. The per-tree application rates and the costs by tree trunk diameter are shown in Table 1. We average the costs per tree across two tree trunk diameter ranges: between 4.25”–6” and >6”. These are the trees most likely chosen for injections. The average cost of the OTC formulation is $0.241/tree.

2. Injection device:

i. There are multiple injection devices on the market at different price points — the highest was $17 per device. Growers reported using lower-cost alternatives that averaged $4 per device. We use the grower-reported cost of $4 per device in our budgets.

ii. Growers reported that each injection device has approximately 50 uses, including cleaning and repairing. This translates to 0.02 devices per tree since each tree is injected once a year. It costs $1.98 to repair a device, which includes the cost of replacing the valve and the rubber tubing.

3. Machinery, equipment, and fuel:

i. A mixing station consists of mixing tanks, pumps, water tanks, generators, and guns for filling injection devices, among other components. We do not consider machinery depreciation and salvage value and assume the mixing station will last for 500,000 tree injections. Based on grower communications, we assume that a mixing station that can support injecting 500,000 trees costs $7,500 ($0.015/tree).

ii. Ten drills are required to inject 500,000 trees. We assume that a drill lasts 5 years. The price of an average handheld power drill with battery and charger, obtained from Home Depot, is $70. We assume that a rechargeable battery for a drill lasts as long as the drill lasts and that the cost of charging the drill batteries is negligible. For the size of trees used in this calculation, 17/64” drill bits are required. We assume that each drill bit is changed every 12,000 trees, costing $5 per replacement. Thus, in total, it costs $0.0044/tree for drills and drill bits.

iii. Fuel is required by ATVs and trucks for carrying workers and equipment. We assume that fuel costs are $4/acre.

4. Labor:

i. We assume that workers cover 25 acres every day. The cost of contract labor is $21/hour. This includes the H2A wage rate of $14.33/hour and the costs of accommodation, paperwork, supervision, and transportation. It takes 10 workers working 10 hours a day to cover 25 acres of grove with a density of 200 trees/acre. Thus, each man-hour can cover 50 trees per day. It will take 3 man-hours to cover a 1-acre grove with a density of 150 trees/acre, and 4 man-hours to cover a 1-acre grove with 200 trees/acre.

5. Cost of citrus production without OTC:

i. The per-acre costs of producing oranges are based on our discussions with growers who indicated that it costs, on average, $1,800 per acre per year for a 150-tree/acre grove and $2,200 per acre per year for a 200-tree/acre grove.

Analysis and Discussion

The trunk injection budgets for 150 trees/acre and 200 trees/acre groves based on the assumptions above are in Tables 2 and 3, respectively. Our analysis found that the total cost, on average, of an OTC trunk injection operation is $0.82/tree. While per-acre costs increase with tree density, the per-tree cost of the operations decreases with tree density. For a 150-tree/acre grove, the cost is $124.01/acre ($0.827/tree), which increases to $164.01/acre ($0.820/tree) when the tree density is 200 trees/acre (Table 4). Trunk injection increases the total cost of orange production by 6.9% for 150 trees injected per acre and by 7.5% for 200 trees injected per acre (Table 4).

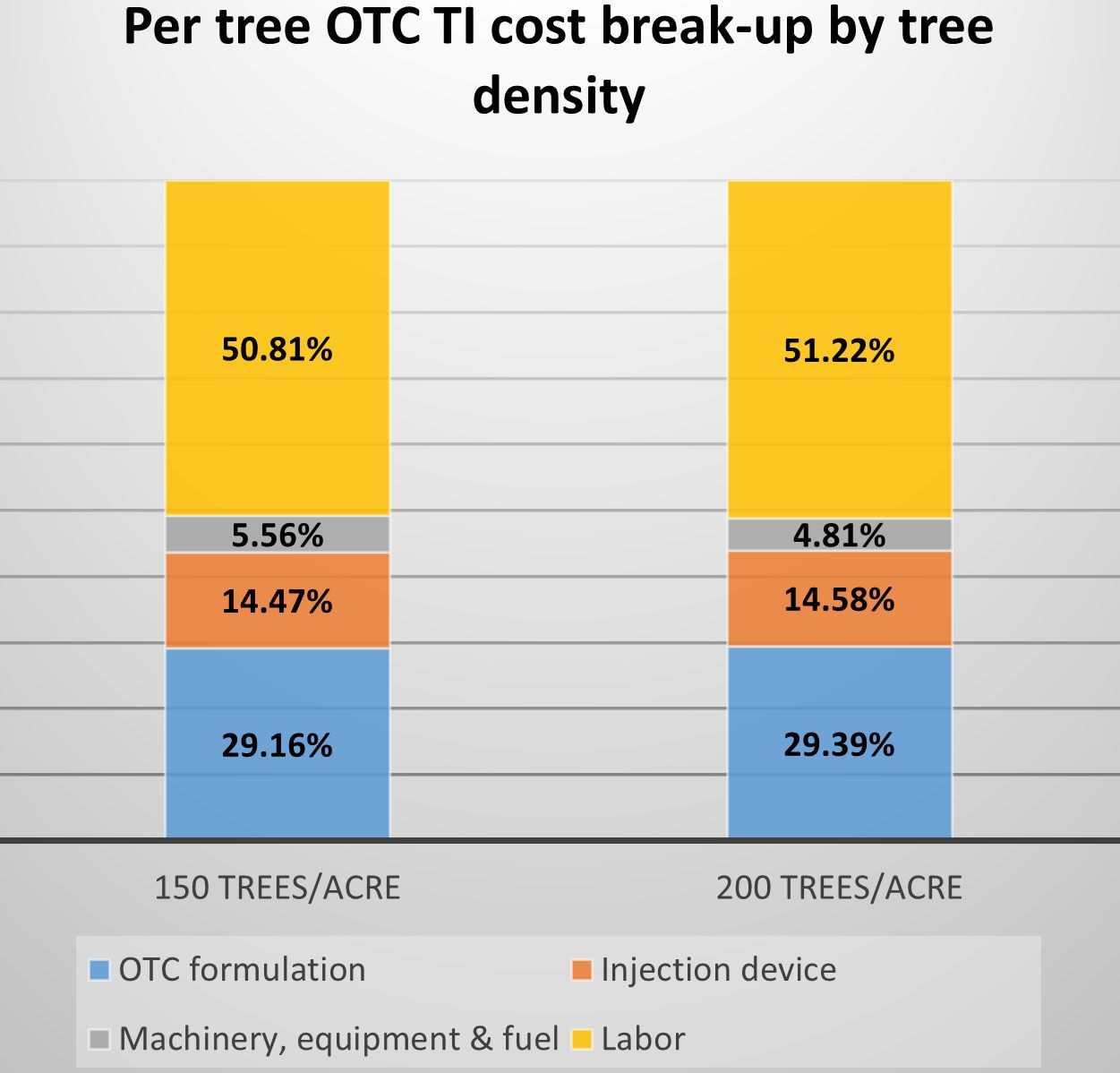

The differences in costs by grove density show the effects of economies of scale. Sunk costs like machinery, equipment, and fuel are expected to decrease with increased grove density, while variable costs like labor and chemicals remain constant per tree. This effect is highlighted in Figure 1, which illustrates the per-tree break-up costs of OTC trunk injection by grove density. As expected, the share for variable per-tree costs does not vary widely by grove density, with labor, OTC chemical cost, and injection devices constituting about 51%, 29%, and 14.5% of the total per-tree costs, respectively. Although the mixing station is a significant investment ($7,500), the total per-acre cost, including drills and fuel, is the lowest among the primary cost items and is affected by the scale of the operation: 5.6% of per-tree costs for groves with 150 trees/acre and 4.8% for groves with 200 trees/acre. There are savings in machinery, equipment, and fuel costs for groves with higher tree densities.

Credit: UF/IFAS

OTC chemical use is the second most expensive cost category and the one that may vary most widely across groves given the heterogenous nature of tree age, health, and size. Recall that we use 8,250 ppm of OTC, an average of the range of OTC concentrations from 5,500 ppm to 11,000 ppm. Using the formulations at the higher end of this range could affect costs. A grower who used 11,000 ppm, recommended for healthy bearing trees, would pay $0.386/tree for chemical costs and the total costs of trunk injection operation would increase to $0.972/tree for a 150-tree/acre grove and $0.965/tree for a 200-tree/acre grove.

We estimate the total cost of production, including trunk injection, to be $1,924.01/acre for a 150-tree/acre grove and $2,364.01/acre for a 200-tree/acre grove. With an on-tree price of $9.05/box for Valencia oranges in 2022–23 (USDA NASS 2024), a simple back-of-the-envelope calculation shows that a Valencia orange grove should yield about 213 boxes/acre for groves with 150 trees/acre and 261 boxes/acre for groves with 200 trees/acre to break even with an OTC trunk injection operation.

The practice appears economically feasible, as recent research shows that OTC injections can increase yields in mature Valencia orange trees by 30% to over 60% (Archer et al. 2023; Albrecht 2023). Moreover, the two growers we interviewed anticipate up to a 30% increase in revenues, driven by higher yields and enhanced fruit quality from OTC applications. Adoption success depends on the exact characteristics of a grove, including baseline yields and fruit quality, growers’ long-term objectives, severity of HLB, prices of orange soluble solids, and other factors.

Summary

HLB has devastated the citrus industry in Florida, and OTC trunk injection could be a viable option for controlling the CLas bacterium. We interviewed three large-scale southwest Florida growers who are early adopters of OTC trunk injections and created detailed partial budgets for OTC trunk injection for 150-tree/acre and 200-tree/acre groves. We found that the average cost of OTC trunk injection for large-scale growers is $0.82/tree or $124.01/acre for groves with 150 trees/acre and $164.01/acre for groves with 200 trees/acre. Labor is the largest per-tree cost component (51%), followed by OTC chemical costs (29%). OTC concentrations will vary depending on tree density and other grove characteristics and can substantially increase the per-tree cost of OTC operations. On average, OTC trunk injection is expected to increase the cost of production by 7%.

The budgets estimate the cost of OTC adoption if growers do the practices themselves. Growers can expect a 10% increase in overhead costs if they use contractors for their operations. Smaller growers can also expect higher costs since they are less likely to take advantage of the benefits from economies of scale observed with the larger growers interviewed.

References

Albrecht, U. 2023. “Research Update on Oxytetracycline Injection for HLB Management.” Citrus Industry Magazine. https://citrusindustry.net/2023/10/16/research-update-on-oxytetracycline-injection-for-hlb-management/

Albrecht, U., L. Archer, and P. Roberts. 2023. “Antibiotics in Crop Production.” HS1366. EDIS. https://edis.ifas.ufl.edu/publication/HS1366

Archer, L., and U. Albrecht. 2023. “Evaluation of Trunk Injection Techniques for Systemic Delivery of Huanglongbing Therapies in Citrus.” HortScience 58(7): 768–778. https://doi.org/10.21273/HORTSCI17172-23

Archer, L., U. Albrecht, and J. Crane. 2021. “Trunk Injection to Deliver Crop Protection Materials: An Overview of Basic Principles and Practical Considerations: HS1426, 11/2021.” EDIS 2021(6). https://doi.org/10.32473/edis-hs1426-2021

Archer, L., J. H. Crane, and U. Albrecht. 2022. “Trunk Injection as a Tool to Deliver Plant Protection Materials — An Overview of Basic Principles and Practical Considerations.” Horticulturae 8(6): 552. https://doi.org/10.3390/horticulturae8060552

Archer, L., S. Kunwar, F. Alferez, O. Batuman, and U. Albrecht. 2023. “Trunk Injection of Oxytetracycline for Huanglongbing Management in Mature Grapefruit and Sweet Orange Trees.” Phytopathology 113(6): 1010–1021. https://doi.org/10.1094/PHYTO-09-22-0330-R

Batuman, O., K. Britt-Ugartemendia, S. Kunwar, S. Yilmaz, L. Fessler, A. Redondo, K. Chumachenko, S. Chakravarty, and T. Wade. 2024. “The Use and Impact of Antibiotics in Plant Agriculture: A Review.” Phytopathology. https://doi.org/10.1094/PHYTO-10-23-0357-IA

Berger, C., and F. Laurent. 2019. “Trunk Injection of Plant Protection Products to Protect Trees from Pests and Diseases.” Crop Protection 124: 104831. https://doi.org/10.1016/j.cropro.2019.05.025

Cho, A. H., A. W. Hodges, and C. A. Chase. 2012. “Partial Budget Analysis of Summer Fallows for Organic Nutrient and Weed Management in Florida.” HortTechnology 22(2): 258–262. https://doi.org/10.21273/HORTTECH.22.2.258

Cruz, J., C. D. Court, and J. P. Ferreira. 2023. “2020–2021 Economic Contributions of the Florida Citrus Industry: FE1155, 8/2024.” EDIS 2024(4). https://doi.org/10.32473/edis-fe1155-2024

Giles, F. 2024. “Florida citrus survey reflects industry optimism.” Citrus Industry Magazine. https://www.mirabelsmagazinecentral.com/digitaledition/index.html?id=88182a03-08fe-4761-9fe2-a28722216be4

Halbert, S. E. 1998. “Entomology Section.” Tri-ology Technical Report 37(4): 5–9.

Hu, J., J. Jiang, and N. Wang. 2018. “Control of Citrus Huanglongbing via Trunk Injection of Plant Defense Activators and Antibiotics.” Phytopathology 108(2): 186–195. https://doi.org/10.1094/PHYTO-05-17-0175-R

Li, J., Z. Pang, S. Duan, D. Lee, V. G. Kolbasov, and N. Wang. 2019. “The in Planta Effective Concentration of Oxytetracycline Against ‘Candidatus Liberibacter asiaticus’ for Suppression of Citrus Huanglongbing.” Phytopathology 109(12): 2046–2054. https://doi.org/10.1094/PHYTO-06-19-0198-R

Singerman, A. 2023. “How much yield is needed to offset the cost of injecting trees with oxytetracycline?” Citrus Industry Magazine. https://citrusindustry.net/2023/10/25/how-much-yield-is-needed-to-offset-the-cost-of-injecting-trees-with-oxytetracycline/

Tigner, R. 2018. “Partial Budgeting: A Tool to Analyze Farm Business Changes.” Iowa State University Extension and Outreach Ag Decision Maker. https://www.extension.iastate.edu/agdm/wholefarm/pdf/c1-50.pdf

USDA NASS. 2023. Florida Citrus Statistics 2021–2022. https://www.nass.usda.gov/Statistics_by_State/Florida/Publications/Citrus/Citrus_Statistics/2021-22/FCS2022.pdf

USDA NASS. 2024. Florida Citrus Statistics 2022–2023. https://www.nass.usda.gov/Statistics_by_State/Florida/Publications/Citrus/Citrus_Statistics/2022-23/FCS2023.pdf

Wise, J. C., A. H. VanWoerkom, S. G. Aćimović, G. W. Sundin, B. M. Cregg, and C. Vandervoort. 2014. “Trunk Injection: A Discriminating Delivering System for Horticulture Crop IPM.” Entomol. Ornithol. Herpetol. 3(2): 126.

Table 1. Costs of oxytetracycline (OTC) formulation and application rates based on an average application concentration of 8,250 ppm.

Table 2. Oxytetracycline (OTC) trunk injection (TI) cost details for a grove with a tree density of 150 mature trees/acre injected once per year.

Table 3. Oxytetracycline (OTC) trunk injection (TI) cost details for a grove with a tree density of 200 mature trees/acre injected once per year.

Table 4. Summary of oxytetracycline (OTC) trunk injection (TI) and production cost of oranges.