Credit: Michele Wood UF/IFAS Communications

Contents

- Stonefruits in Florida—Introduction

- Stonefruit Quality—Evaluation and Measurement

- Stonefruit Cultivars for Florida

- Postharvest Physiology of Stonefruits

- Stonefruit Harvest Operations

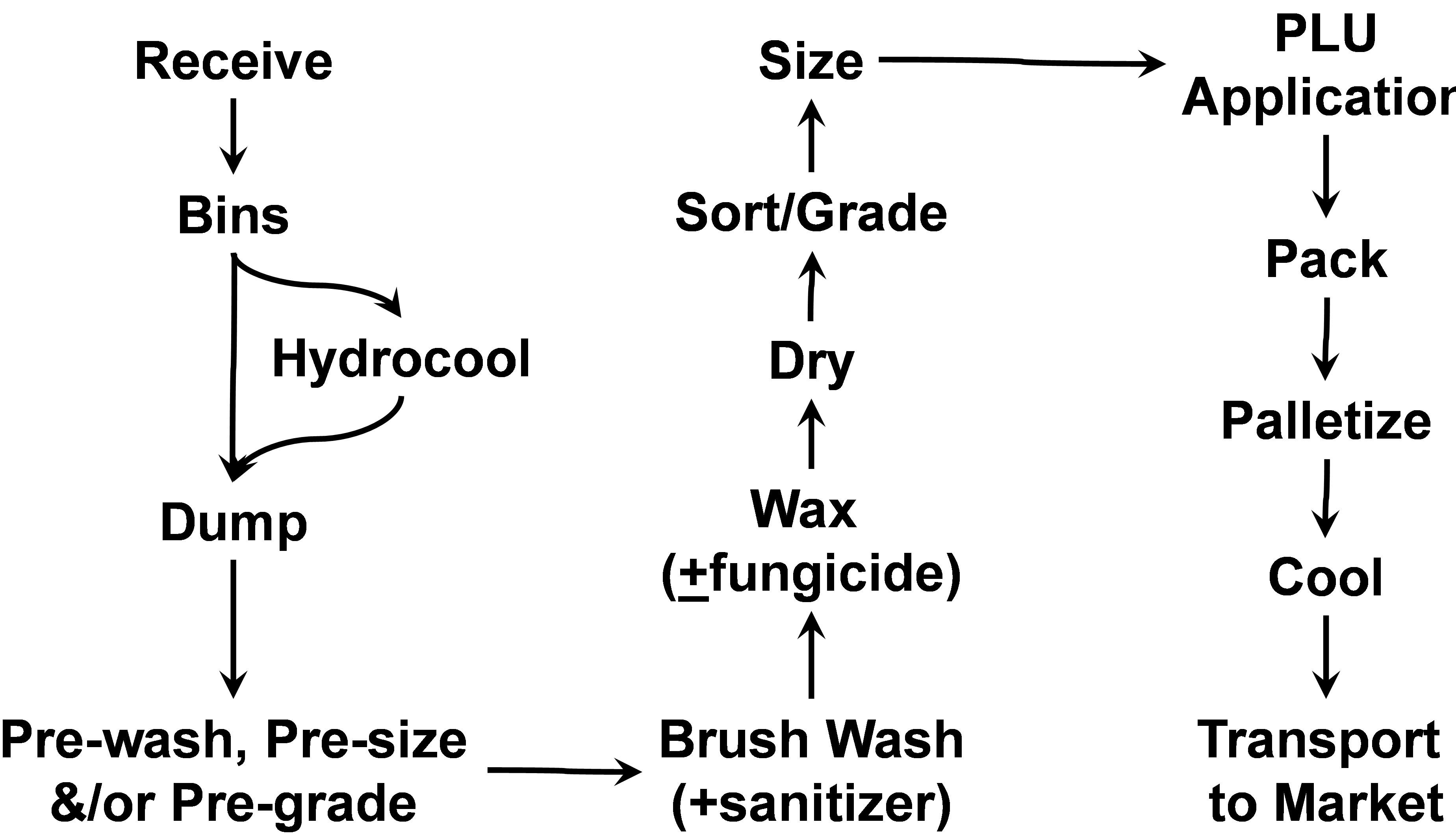

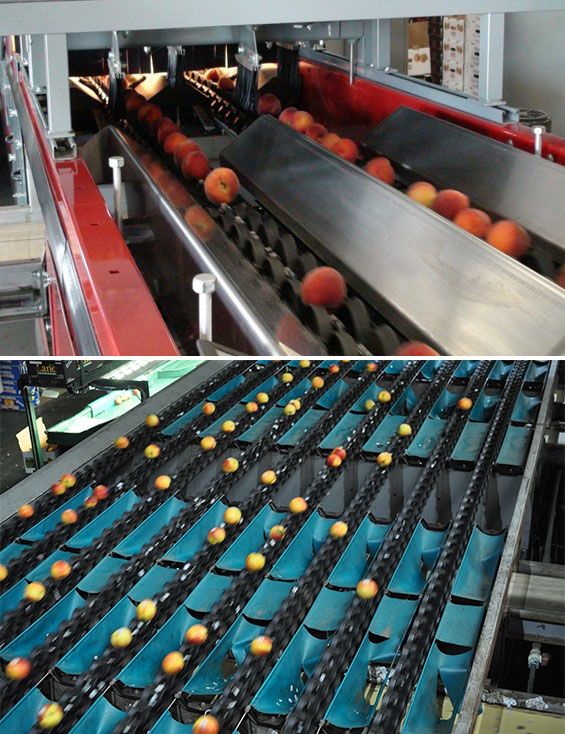

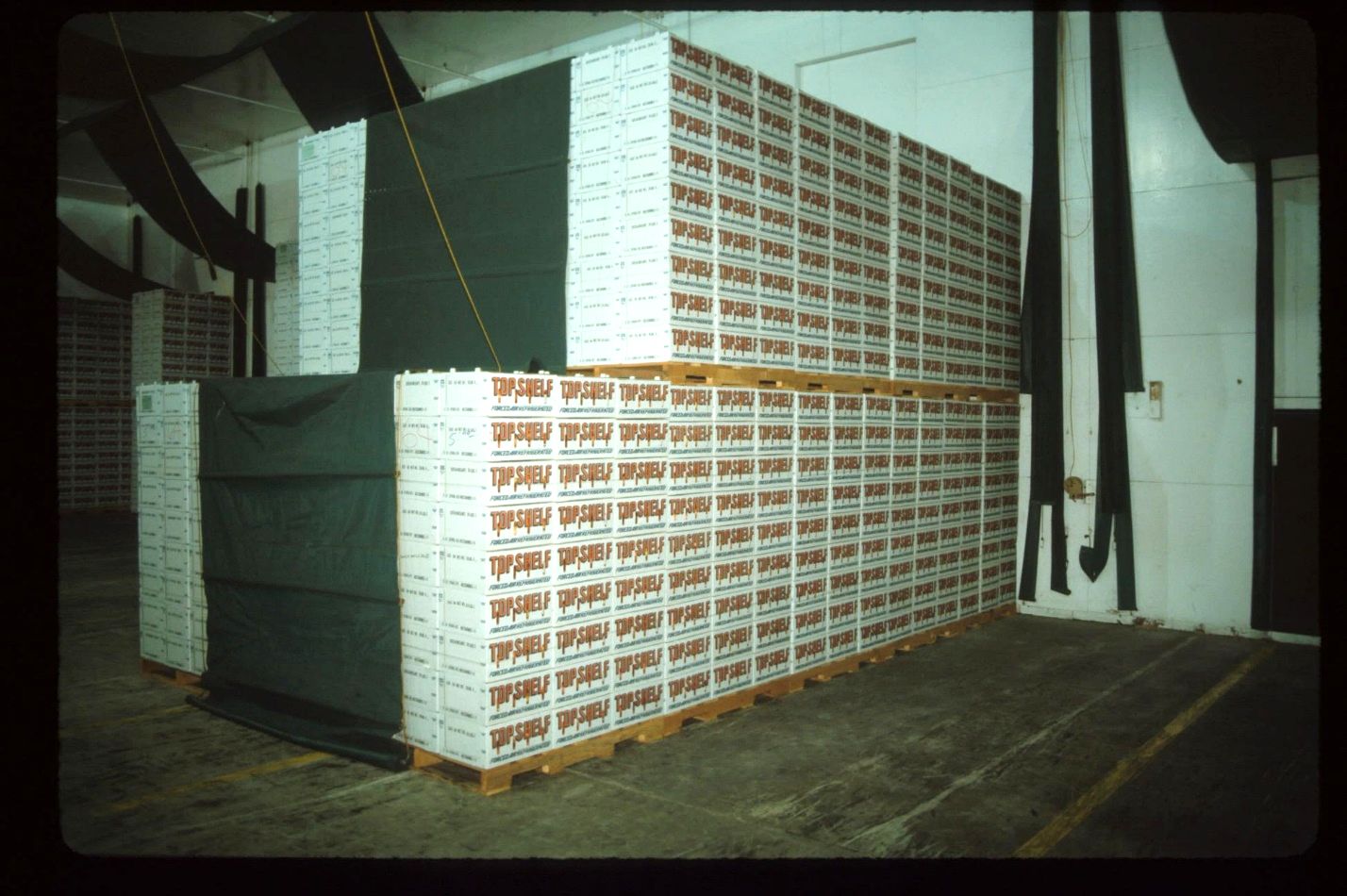

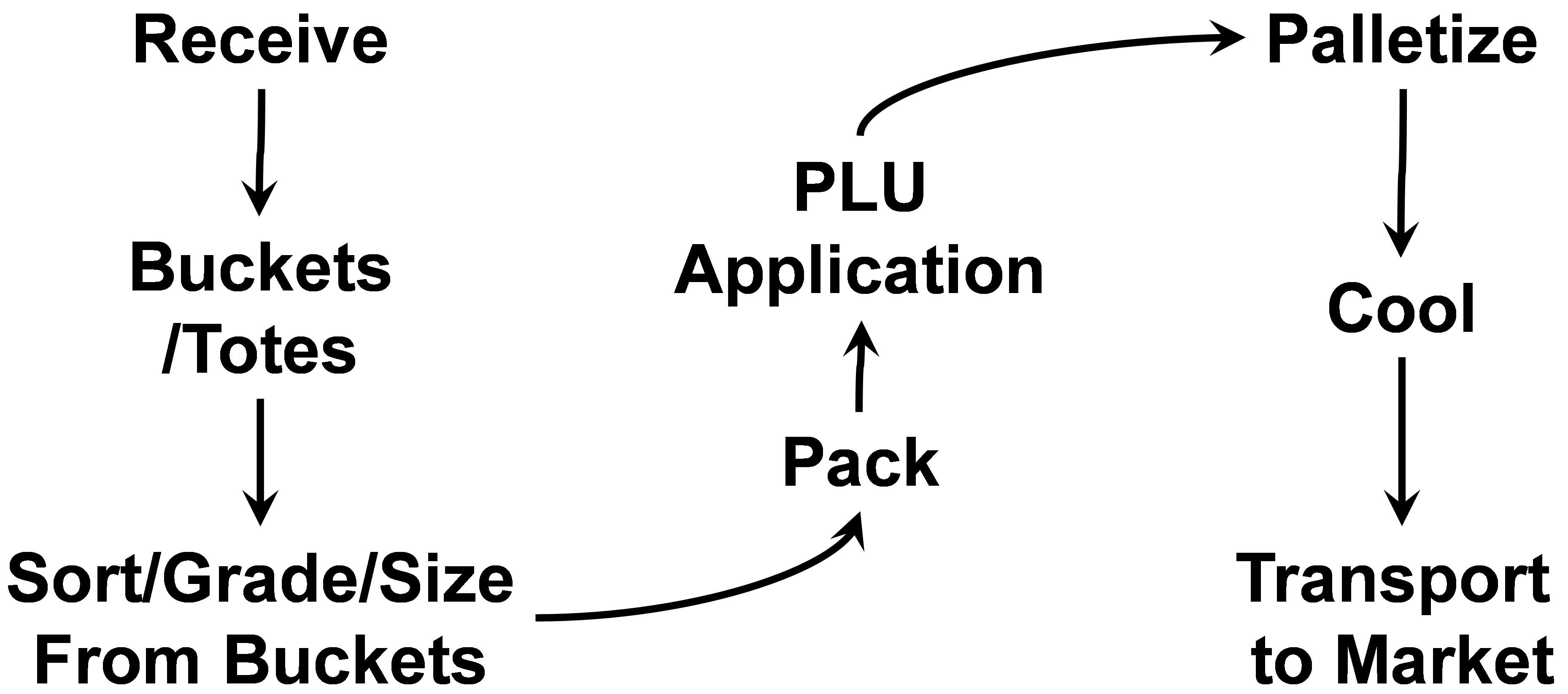

- Stonefruit Packing Operations

- Controlling Postharvest Decays of Stonefruits Grown in Florida

- Managing the Postharvest Environment – Best Practices for Stonefruit Precooling, Storage, and Shipping

- Postharvest Stonefruit Defects and Disorders

- Distribution, Marketing, and Consumer Handling of Florida Stonefruits

1. Stonefruits in Florida – Introduction

Ali Sarkhosh and Mercy A. Olmstead

Growers of many high-value horticultural commodities have taken advantage of the subtropical climate in Florida to become the earliest domestic source of several fruits and vegetables during the winter and spring months, leading to profitable endeavors. Currently, Florida produces some of the earliest commercial-quality stonefruit (peach, nectarine, and plum) in North America. The low-chill cultivars of stonefruit developed by the Stonefruit Breeding Program operated by the University of Florida Institute of Food and Agricultural Sciences (UF/IFAS) do not require as much winter chilling to produce fruit as traditional cultivars that are grown farther north in the United States. These peach, nectarine, and plum cultivars, whose names all begin with “UF,” allow growers to produce an early-ripening, high-quality fruit with excellent flavor. For example, ‘UFSun’ (Figure 1-1) and ‘UFBest’ peaches, which are adapted to central- and south-central Florida, have a fruit development period (FDP) from bloom to harvest of approximately 80 days. When grown in south-central Florida, they ripen in early April and are among the first commercial peaches to harvest in North America. ‘UFSun’ and ‘UFBest’ are followed closely in ripening sequence by several other peach and nectarine cultivars adapted for south-central to northern Florida. In 2017, the Florida peach industry produced over 3,000 tons of fruit from an estimated 2,000 acres (Harders et al. 2017).

Credit: Ali Sarkhosh, UF/IFAS

From North to South: Breeding Program History

Although there were about 4,000 acres of stonefruit in Florida in the late 1970s and early 1980s, predominantly located in northern Florida, a combination of market factors and severe weather events led to the overall decline of the peach industry in the southeastern United States. A major contributor to the decline of peach acreage was the lack of frost-protection systems during the 1980–89 freezes, which led to the removal of several thousand acres of peaches. However, UF/IFAS continued the Stonefruit Breeding Program and released several new cultivars, many of which are grown worldwide.

Dr. Ralph Sharpe began the UF/IFAS's Stonefruit Breeding Program in 1952 with the goal of taking advantage of Florida's climate, land, and market window to produce some of the earliest fruit in the United States (Sherman et al. 1996). Florida's environment is unique in the continental United States. Our climate is subtropical and monsoonal, which means that it affords stonefruit trees a relatively long period of growth postharvest. Producers have capitalized on the unique benefits of the Florida climate to deliver the earliest domestic production of high-value commodities such as vegetables, tomatoes and peppers, and fruit, like strawberries and blueberries.

Peaches and nectarines (Prunus persica L. Batsch.) are related to species of Prunus native to China (Bassi and Monet 2008). Peaches, nectarines, and other stonefruit originate from temperate climates that require exposure to cold temperatures for flowering and resumption of vegetative growth in the spring. The amount of cold required for growth is measured in chill units. A chill unit is a period of time between 32 °F and 45 °F (0 °C –7 °C) that accumulates through the winter months (Richardson et al. 1974). A temperate fruit crop requires a certain number of chill units to bloom and bear fruit. However, in Florida, which is considered a subtropical environment, chill units do not accumulate to the extent that they do in temperate climates. Thus, the germplasm used in the UF/IFAS breeding program had to include low-chill sources of material, including some from southern China. Of these importations of germplasm, the most important was that from Okinawa, Japan. This plant material provides the backbone low-chill cultivars in the UF/IFAS breeding program.

Dr. Wayne Sherman succeeded Dr. Sharpe as the UF/IFAS stonefruit breeder in January of 1966. Dr. Sherman was responsible for several improvements that increased the efficiency of the breeding program and reduced the time from making a cross to the release of a new cultivar. He developed the fruiting nursery, correlated early ripening with the appearance of red leaves, and began the use of the non-melting-flesh type for fresh fruit production.

Peaches are typically available in two different flesh types, melting and non-melting. Melting-flesh peaches undergo a rapid softening of the flesh as the fruit ripen. Historically this type of fruit has been used for fresh fruit production. Non-melting-flesh peaches are characterized by a firm flesh phenotype that softens slowly, resulting from a natural mutation that was identified hundreds of years ago. Non-melting-flesh peaches are primarily used for processing. Melting-flesh cultivars typically do not ship as well as they approach physiological ripeness because of their tendency to bruise easily, and thus are harvested much earlier to withstand transport within the marketing chain. With an early harvest, sugar levels (often measured as °Brix), flavor, and color may not be as well developed. Fruit quality is an important consideration for consumers that make return purchases (Crisosto 2002); however, it can be difficult to achieve in early-ripening cultivars (Sharpe et al. 1954).

In order to develop peach cultivars that could be harvested when “physiologically mature” so as to achieve higher fruit quality, non-melting-flesh genes in plant material from Mexico, North Carolina, and Brazil were brought into the UF/IFAS breeding program. These genes were used to breed non-melting-flesh peach cultivars that can be harvested at a more mature (ripe) stage with a firm texture, greater flavor, increased color development, and higher sugar content. Recent research has shown that non-melting fruit must be harvested later than melting-flesh cultivars, to develop optimum flavor profiles associated with high-quality fruit, allowing fruit to stay on the tree until physiologically mature (Kao et al. 2008). Growers and fruit marketers have taken advantage of this fruit quality trait to promote a true “tree-ripe” product.

Chilling Requirement

Stonefruits are temperate-zone tree fruits that require a minimum amount of accumulated cold temperature exposure (between 32°F [0°C] and 45°F [7°C]) to resume normal growth the following spring. This is referred to as the cultivar’s chilling requirement (Richardson et al. 1974; Sherman and Rodriguez-Alcazar 1987; Sharpe et al. 1990). The chilling requirement is usually expressed in chill units (cu). It counts any hour between 32°F–45°F (0°C–7°C), temperatures which, in Florida, occur predominantly from October to the first week of January. Each cultivar has its own characteristic chilling requirement, which partially determines its adaptability to a certain region of the state (Table 1-1, Figure 1-2). The importance of proper site and cultivar selection must be emphasized. For example, ‘Gulfcrest’ (525 cu) is adapted to north Florida (Panhandle region) but would not receive sufficient chilling most winters to grow well in Gainesville. Conversely, if the cultivar’s chilling requirement is too low for the area where it is planted, there is a greater chance of late-winter frosts killing blossoms and young fruit. More peaches and nectarines are lost to frost damage in the southeastern United States than to any other single cause.

Table 1-1. Chilling requirement characteristic of UF/IFAS peach and nectarine cultivars (Sarkhosh et al. 2018a).

![Figure 1-2 Chill units accumulated (between 32°F [0°C] and 45°F [7°C]) through February 10 in 75% of winters.](/image/HS1459/Dgc11qlc51/Iywz3abel8/Iywz3abel8-2048.webp)

Credit: UF/IFAS

Plums could be a potential crop for growers and homeowners in Florida and other mild winter areas throughout the Gulf coast, but many plum cultivars from the western United States will not consistently perform well enough in Florida to produce fruit. However, the UF/IFAS Stonefruit Breeding Program has developed cultivars that improve the potential for growing plums in Florida and other mild winter areas with high disease pressure. These cultivars are recommended for trial in Florida. The names of all the UF/IFAS plum cultivars begin with the prefix ‘Gulf’. These cultivars are Japanese type plums (Prunus salicina Lindl.) and have resistance to plum leaf scald (Xylella fastidiosa) and bacterial spot (Xanthomonas campestris). Fruit size is satisfactory (about 1½ to 2 inches in diameter) with good fruit quality. They ripen in early to late May, approximately 2 weeks before plums from other areas arrive in the marketplace (Sarkhosh et al. 2018b).

Marketing Situation

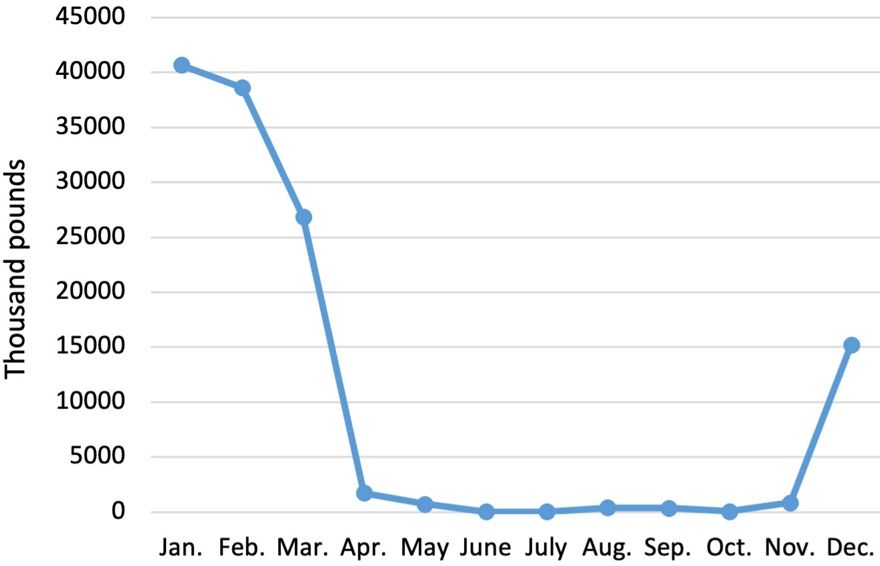

The incentives for growing peaches and nectarines in Florida are 1) production and marketing of fresh Florida peaches and nectarines before central Georgia, South Carolina, and California enter the market, and 2) production of quality fruit when there is almost no other quality fresh fruit of any kind available (Figure 1-3). Peaches and nectarines can be produced continuously from late March until late May or early June in Florida, depending on the weather. As precipitation increases during the summer months, disease and pest problems on peaches and nectarines also increase. Later-maturing cultivars have little or no potential in Florida because of increased pest and disease pressure and increased market competition.

Credit: Economic Research Service, USDA-ARS

To market high-quality peaches, it is necessary to harvest each cultivar three to four times at 2-day intervals in order to obtain fruit that are tree ripe. When harvested at this stage, fruit have the highest potential for flavor. For long-distance shipment, fruit must be carefully handled, graded, sized, cooled, and packed. This requires a sizable investment in a packinghouse, which is not likely to prove economically feasible with much less than 100–150 acres. However, marketing alternatives for smaller growers include joining a grower cooperative; making direct sales to grocery stores or produce markets; and opting for U-pick, farmers’ markets, or roadside stand operations. It is important to grow at least two to three cultivars that ripen in succession to ensure a steady flow of ripe fruit. This longer harvest period helps with the marketing and efficient use of harvest labor and packing facilities.

Commercial peach and nectarine operations in the southeastern United States can have pre-harvest production costs of about $4,000 per acre (Morgan et al. 2010; M. Olmstead personal communication). For more information about production cost and profitability of peach orchards, please refer to the publication Establishment and Production Costs for Peach Orchards in Florida: Enterprise Budget and Profitability Analysis (Singerman et al. 2017). Establishment costs vary depending on the grower’s situation. Costs will be lower, for instance if the land is already purchased and irrigation is available from a previous crop. Because marketing costs for commercial orchards are relatively high, U-pick operations have the potential to greatly reduce total costs. Estimated returns (gross) to peach growers in Florida are approximately three times greater than those of growers in surrounding southeastern states (United States Agricultural Statistics Board 2011).

Labor

Peach and nectarine production requires high levels of seasonal hand labor. Commercial growers hire labor for dormant and summer pruning, fruit thinning, and harvesting. Family operations often supply their own labor. Timing of labor operations is especially critical; often a delay of a few days in harvesting can result in profit loss. Currently, the greatest cost of peach production in Florida is hand thinning and manual pruning. These practices together require around 150 hours per acre depending on tree size and fruit set, resulting in an estimated cost of approximately $2,000/ acre per year.

Planting Guidelines

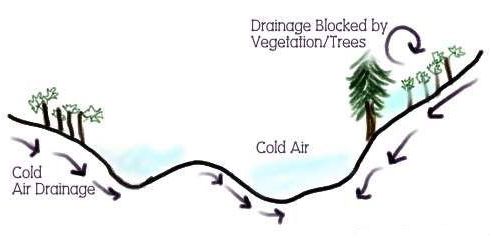

Peaches and nectarines should only be planted on sites with excellent air drainage to reduce the risk of frost damage to flowers. Cold air is denser and sinks to the lowest spot in the orchard, especially on nights with radiation freezes. Radiation freezes occur on clear nights with calm wind conditions, when warm air rises as the cold air sinks (Figure 1-4). An advective freeze is dominated by windy conditions and often results in severe damage to the flowers and potential fruit. On a good site, select cultivars with chilling requirements slightly less than the average chilling received in that location. This helps ensure adequate chilling during unusually warm winters; if the site has excellent air drainage, the risks of flower damage from spring freezes will be minimal during normal and high-chill years.

Credit: M. Olmstead, UF/IFAS

Site selection and cultivar choice rank as the two most important factors in successful peach and nectarine growing. When selecting a site, avoid low areas characterized by late spring frosts. Even in central Florida, freezes can occur throughout February and early March in cold locations; thus, sites with good air drainage are essential for reliable production. Planting an orchard with the proper site and cultivar will allow growers to maximize their establishment efficiency with the minimum number of replanted trees.

Peaches and nectarines can be grown on a wide variety of soils, provided the upper 4–6 feet of soil is well-drained. Avoid “hardpan” soils unless an excellent system of subsoil drainage tiles or a bedded system is installed. Irrigation is required throughout the trees’ growth and fruit development periods to obtain acceptable fruit size and yields. A properly designed overhead sprinkler irrigation system has the added advantage of protecting flowers and young fruit from late winter and spring freezes. For low-volume irrigation systems, micro-sprinklers are preferred to drip emitters. To avoid spraying seedlings/trees, a truck with water micro-sprinklers with 240 to 300 degrees spraying pattern is recommended.

June-budded trees that are 2 ½–4 feet high are a good size to plant during the fall season, while larger sizes are more difficult to handle and expensive. Normal tree spacing is 15 x 20 feet, or 145 trees per acre. On lighter soils, higher density plantings have been satisfactory (Table 1-2). All Florida peach and nectarine cultivars are self-fruitful and should be planted in solid blocks for easier spraying and harvesting.

Table 1-2. Various tree and row spacing for orchard establishment.

Cultural Program

Growing peaches and nectarines requires a high level of skilled management, which includes pruning, fruit thinning, harvesting, and scouting for pests and diseases (Figure 1-5). Peach and nectarine trees are susceptible to a number of health challenges, including diseases, insects, and nematodes. Root-knot nematodes (Meloidogyne incognita and M. javanica) are common in Florida soils and can weaken peach and nectarine trees. In addition, peach root-knot nematode, M. floridensis (Handoo et al. 2004), can infect common peach rootstocks such as ‘Nemaguard’ and ‘Okinawa’. Therefore, only M. floridensis root-knot nematode-resistant rootstocks such as ‘Flordaguard’ or ‘MP-29’ should be used in Florida (Sherman et al. 1991; Sarkhosh et al. 2018c). An integrated pest management program must be followed to ensure good fruit quality. Although some diseases and insects can be severe, they can usually be controlled with a proper pest management program. A disease and pest management guide is available online at the UF/IFAS stonefruit website (https://hos.ifas.ufl.edu/stonefruit/).

Credit: Ali Sarkhosh, UF/IFAS

Additional Reading

Bassi, D., and R. Monet. 2008. “Botany and Taxonomy.” In The Peach: Botany, Production and Uses, edited by Layne and Bassi, 1–36. Wallingford, U.K.: CAB International Press. https://doi.org/10.1079/9781845933869.0001

Handoo, Z. A., A. P. Nyczepir, D. Esmenjaud, J. G. van der Beek, P. Castagnone-Sereno, L. K. Carta, A. M. Skantar, and J. A. Higgins. 2004. “Morphological, Molecular, and Differential-Host Characterization of Meloidogyne floridensis n. Sp. (Nematoda: Meloidogynidae), a Root-Knot Nematode Parasitizing Peach in Florida.” Journal of Nematology 36 (1): 20–35.

Harders, K., J. Rumble, T. Bradley, L. House, and A. Sandra. 2016. Consumer Peach Purchasing Survey. PIE2016/17-02. Gainesville, FL: University of Florida/IFAS Center for Public Issues Education. https://www.piecenter.com/wp-content/uploads/2015/09/Peach-Report_FINAL.pdf

Kao, M-W., J. G. Williamson, and J. K. Brecht. 2008. “Optimum Harvest Maturity for Extended Postharvest Quality of Melting and Non-Melting Flesh Subtropical Peach Varieties. HortScience 43:1149–1150.

Morgan, K., J. Braswell, F. Matta, D. Ingram, and B. Layton. 2010. Peach - Fruit and Nut Planning Budgets. Starkeville: Mississippi State University.

Richardson, E. A., S. D. Seeley, and D. R. Walker. 1974. “A Model for Estimating the Completion of Rest for 'Redhaven' and 'Elberta' Peach Trees.” HortScience 9:331–332. https://doi.org/10.21273/HORTSCI.9.4.331

Sarkhosh, A., M. Olmstead, J. Chaparro, P. Andersen, and J. Williamson. 2018a. “Florida Peach and Nectarine Varieties: Cir1159/MG374, Rev. 10/2018.” EDIS 2018:17. https://doi.org/10.32473/edis-mg374-2018

Sarkhosh, A., M. Olmstead, P. C. Miller, P. Andersen, and J. Williamson. 2018b. “Growing Plums in Florida: HS895/HS250, Rev. 9/2018.” EDIS 2018:13. https://doi.org/10.32473/edis-hs250-2018

Sarkhosh, A., M. Olmstead, J. Chaparro, and T. Beckman. 2018c. “Rootstocks for Florida Stone Fruit: HS1110/HS366, Rev. 10/2018.” EDIS 2018 (6). https://doi.org/10.32473/edis-hs366-2018

Sharpe, R. H., T. E. Webb, and H. W. Lundy. 1954. “Peach Variety Tests.” Proceedings of the Florida State Horticultural Society 67:245–246.

Sharpe, R. H., W. B. Sherman, and J. D. Martsolf. 1990. “Peach Varieties in Florida and Their Chilling Requirements.” Acta Horticulturae 279:191–197.

Sherman, W. B., and J. Rodriguez-Alcazar. 1987. “Breeding of Low-Chill Peach and Nectarines for Mild Winters.” HortScience 22:1233–1236.

Sherman, W. B., P. M. Lyrene, and R. H. Sharpe. 1991. “‘Flordaguard’ Peach Rootstock.” HortScience 26 (4): 427–428.

Sherman, W. B., P. M. Lyrene, and R. H. Sharpe. 1996. “Low-Chill Peach and Nectarine Breeding at the University of Florida.” Proceedings of the Florida State Horticultural Society 109:222–223.

Singerman, A., M. Burani-Arouca, and M. Olmstead. 2017. “Establishment and Production Costs for Peach Orchards in Florida: Enterprise Budget and Profitability Analysis: FE1016, 7/2017.” EDIS 2017 (4). https://doi.org/10.32473/edis-fe1016-2017

United States Agricultural Statistics Board. 2011. “Noncitrus Fruits and Nuts 2010 Summary.” National Agricultural Statistics Service (NASS), Agricultural Statistics Board, U.S. Dept. of Agriculture. http://usda.mannlib.cornell.edu/MannUsda/viewDocumentInfo.do?documentID=1113.

2. Stonefruit Quality – Evaluation and Measurement

Jeffrey K. Brecht and Mark A. Ritenour

Producing high-quality stonefruit requires the grower to maintain the trees in an optimum range of nitrogen and water availability; use proper pruning to optimize light penetration into the canopy, which improves fruit size, color, and sugar content; and conduct fruit thinning to achieve maximum size and sugar content in the remaining fruit.

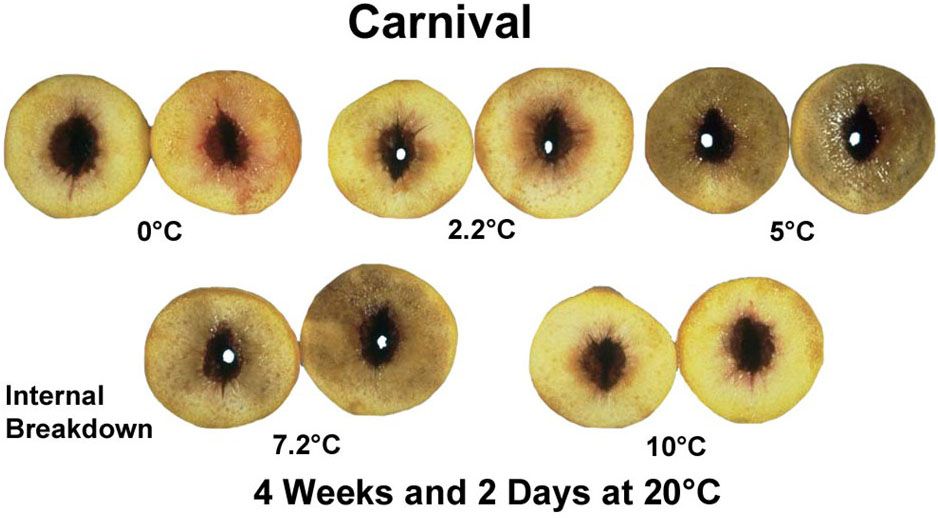

However, the most important factor influencing stonefruit quality is whether the fruit are fully mature at harvest. Short of allowing the fruit to fully ripen on the tree, at least letting the fruit initiate ripening prior to harvesting them results in the best quality fruit for the consumer. Stonefruit that have not fully developed on the tree are more prone to postharvest water loss (shriveling); chilling injury (internal breakdown); and abrasion damage. They are also of inferior quality when ripe. Fruit that are too ripe at harvest, on the other hand, are susceptible to decay and many riper fruit will never make it through packing and transport, being more prone to bruising from impacts and compression. However, most of the stonefruit cultivars from the Stonefruit Breeding Program operated by the University of Florida Institute of Food and Agricultural Sciences (UF/IFAS) have had the non-melting-flesh trait incorporated into them, which allows the fruit to maintain greater firmness as they begin to ripen. Cultivars with the non-melting-flesh trait may be allowed to begin ripening before harvest without becoming too soft to tolerate harvesting, packinghouse handling, and transportation stresses.

United States Standards for Quality of Fresh-Market Peaches. The following section lists the most basic standards that most stonefruits in the marketplace are required to meet. (The first four grades of peaches are a close paraphrase of the language on the USDA peach grades and standards webpage, here: https://www.ams.usda.gov/grades-standards/peach-grades-and-standards.) However, many retailers have more stringent standards. The US standards are primarily based on the visual appearance of the fruit with very small tolerances for soft or overripe fruit.

U.S. Fancy consists of peaches of one cultivar that are mature but not soft or overripe, well-formed, and free from decay, bacterial spot, unhealed cuts, growth cracks, hail injury, scab, scale, split pits, worms, worm holes, leaf or limb rub injury; and free from damage caused by bruises, dirt or other foreign material, other disease, insects or mechanical or other means. This grade requires that the peaches have at least 1/3 of their surface showing blushed pink or red color and that at least 90% of them meet this color standard. U.S. Fancy has a 2% allowance, or tolerance, for soft or overripe fruit at destination.

U.S. No. 1 peaches meet the same standards as U.S. Fancy except for not having a color standard; the fruit should be mature with a 2% allowance for soft or overripe peaches at destination.

U.S. Extra No. 1 peaches meet the requirements of U.S. No. 1 grade, provided that at least 50% of the fruit have at least 1/4 of their surface showing blushed pink or red color. As with U.S. Fancy and U.S. No. 1, no more than 2% of the fruit are allowed to be soft or overripe at destination.

U.S. No. 2 consists of peaches of one cultivar that are mature, but not soft or overripe, not badly misshapen, and free from decay, unhealed cuts, worms, worm holes; and free from damage caused by bruises, dirt or other foreign material, bacterial spot, scab, scale, hail injury, leaf or limb rubs, split pits, other disease, insects or mechanical or other means. There are no color standards for this grade. As with all USDA grades, the tolerance for soft or overripe fruit at destination is only 2%.

U.S. Mature is a standard that covers all U.S. No. 1 peaches, stipulating that the fruit are mature enough to complete the ripening process without additional ethylene exposure. There is a non-severe open suture tolerance of 25%.

Credit: undefined

California Well Matured. This is another standard that is commonly seen in the marketplace. These fruit must be mature enough to complete the ripening process without additional ethylene exposure. The over-blush is usually 90% of total for a given cultivar. Ninety percent of the lot must meet the color standard. There is a non-severe open suture tolerance of 25%.

The quality of stonefruits is related to their highly appreciated and desirable appearance, texture, taste, aroma, and nutritive value. These same aspects of stonefruit quality are used to determine the ripeness and desirability of stonefruit.

Recommended Practices for Evaluating and Measuring Stonefruit Quality

Appearance: Fruit Size, Shape, Defects, and Color

Size and shape of stonefruits are important features for successful marketing. It is possible for pickers and packers to subjectively determine if peaches and other stonefruits are within certain size ranges and that the fruit shape is normal and uniform. Accurate size measurement requires the use of calipers or sizing rings. Weight is also a fairly accurate measure of fruit size if the fruit are uniformly shaped.

Credit: Mark A. Ritenour, UF/IFAS

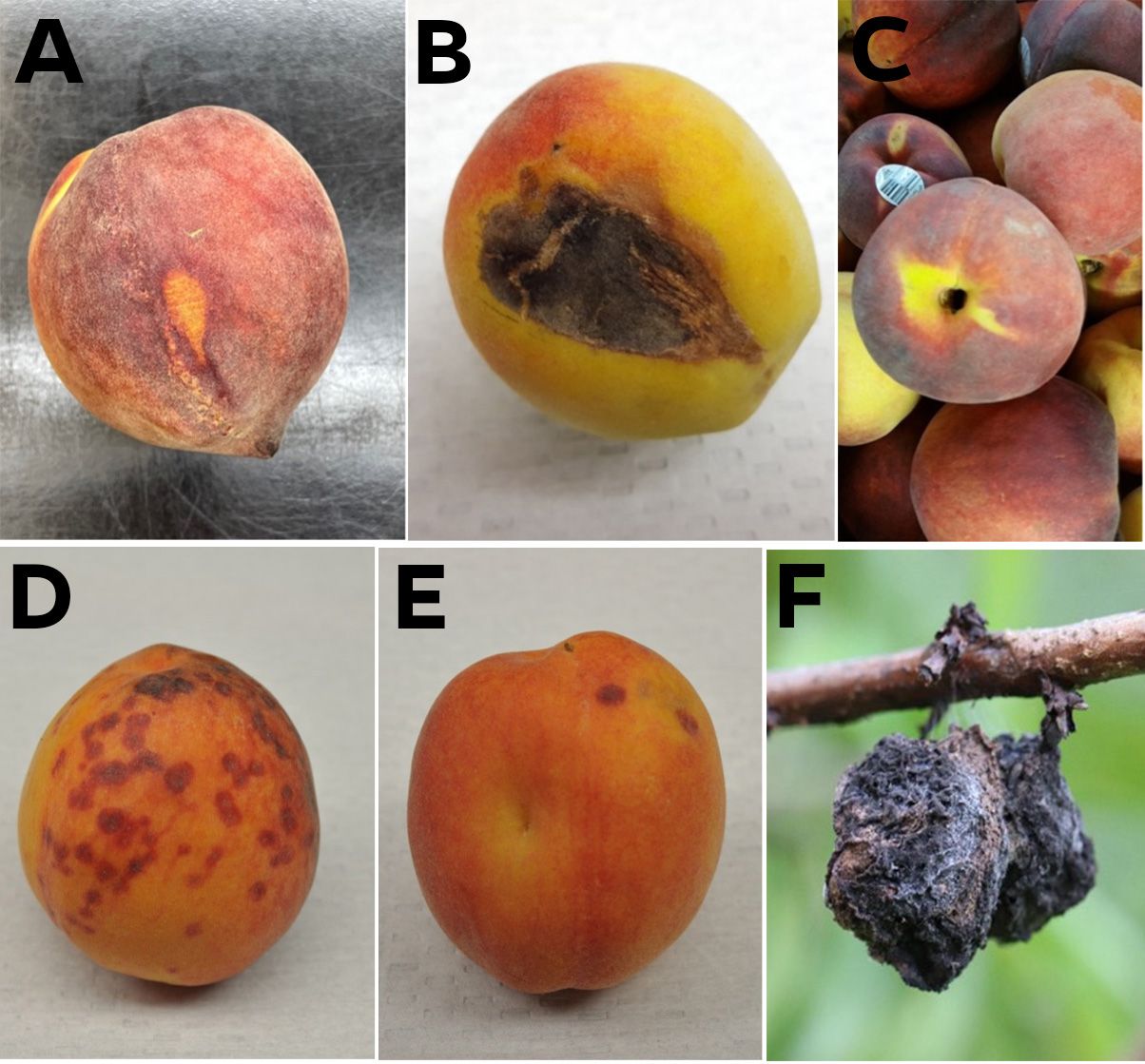

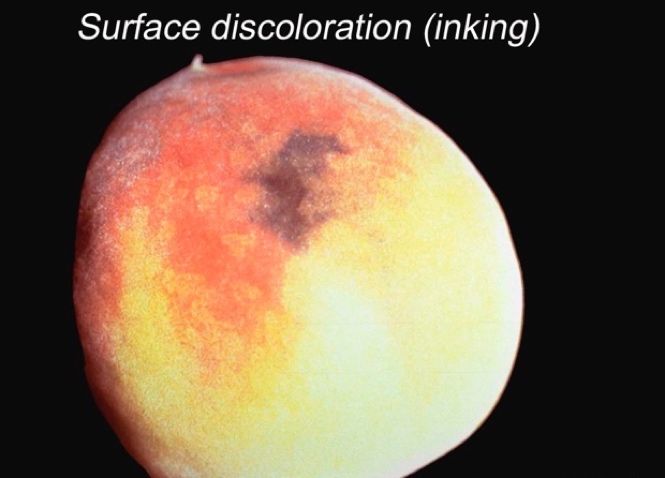

Besides misshapen fruit, defects may include such things as russeting, scarring, split pits, insect evidence, and decay that can be avoided at harvest or graded out on the packingline. Defects also include damage occurring postharvest, such as abrasions and bruising, peel “inking,” and decay that, with the help of visual aids, can be identified and subjectively scored based on incidence and severity.

Credit: A, B, C, D, and E, Mark A. Ritenour, UF/IFAS; F, Phil Harmon, UF/IFAS

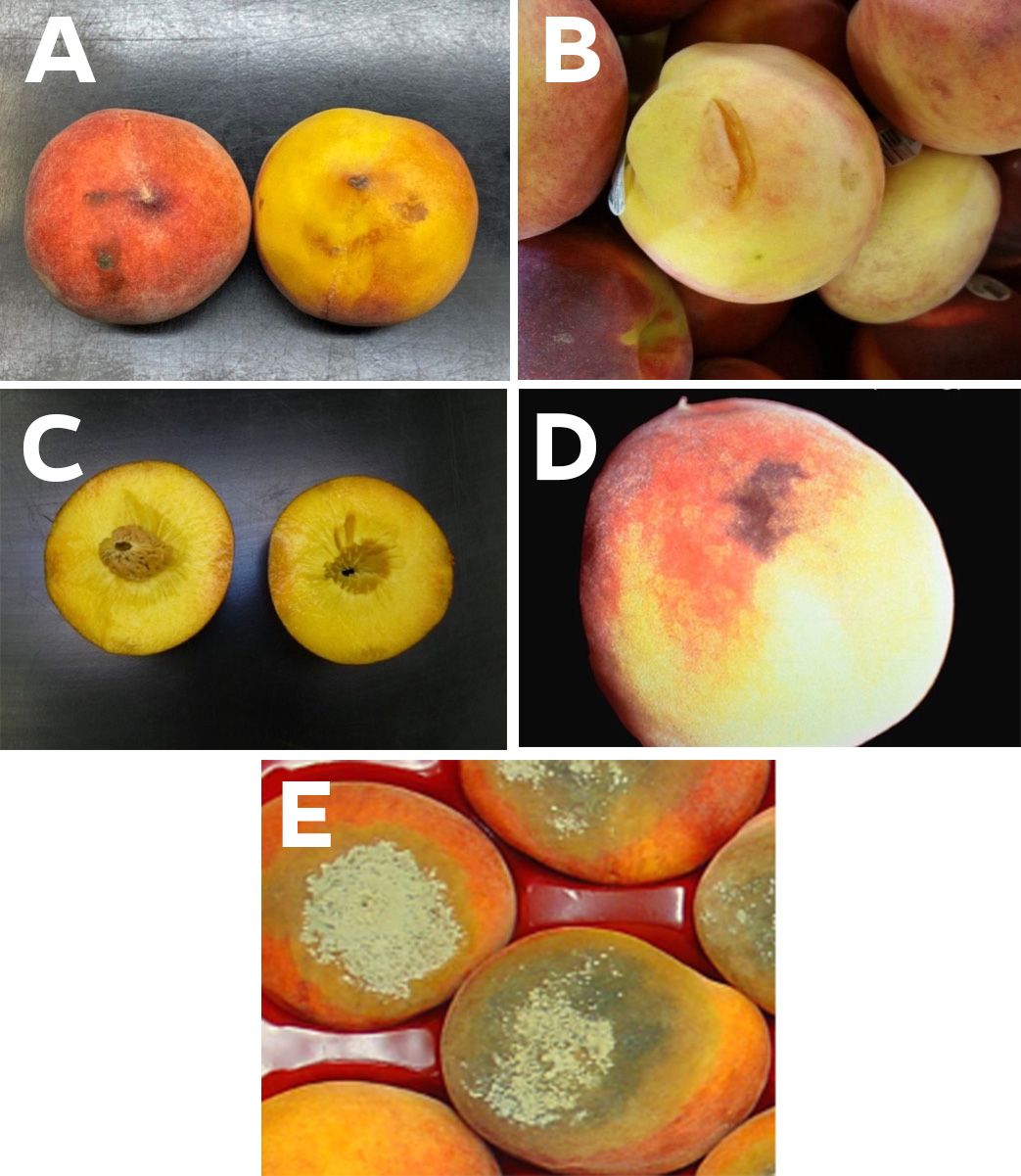

Credit: A, B, C, Mark A. Ritenour, UF/IFAS; D, Carlos Crisosto, UC Postharvest Technology Center; E, Yuru Chang, UF/IFAS

Some types of stonefruits, such as apricots, plums, and processing peaches, may have more or less uniform color on the fruit surface, or, as in fresh-market peaches, there may be a combination of colors. In the latter case, the red color or “blush” is due to exposure to sunlight. While the presence of blush may be important for marketing, it does not have any relationship to ripeness or any other quality aspect of the fruit. More important in terms of quality is the color underlying the blush that changes from green to yellow and sometime orange as peaches and nectarines ripen. This underlying color is called the “ground color” and it is the most important color to which attention should be paid when judging fruit quality and ripeness.

Credit: Jeffrey K. Brecht, UF/IFAS

Color charts and guides have been made for stonefruits in different production areas to assist in evaluating fruit maturity and ripeness. Color charts are usually photographs of fruit at different stages of ripeness. Subjectively scoring color with reference to such a chart can be quite practical and accurate. A popular style of color guide is a ring or color chip with a hole that is meant to be held over the fruit. This design makes matching the fruit and guide colors quite easy.

Credit: Carlos Crisosto, UC Postharvest Technology Center

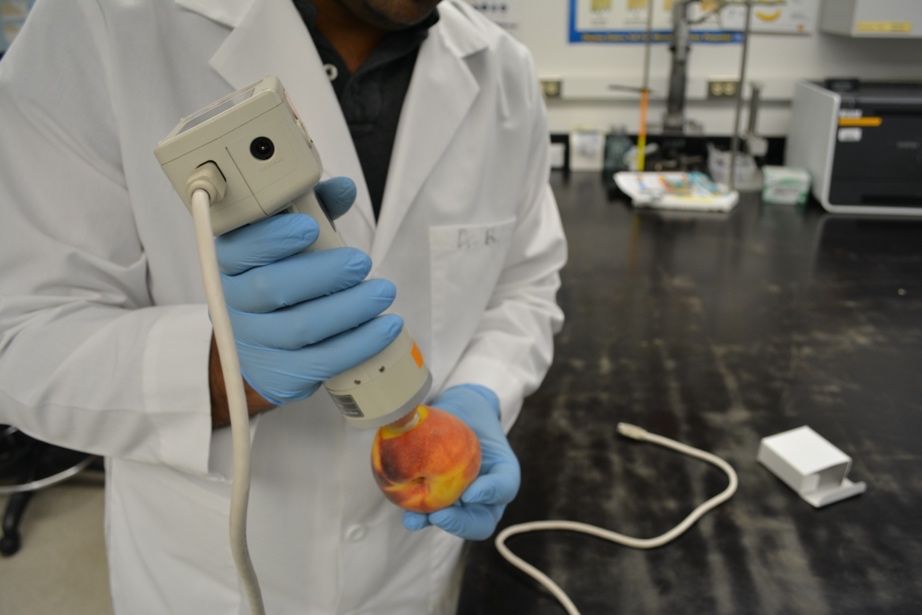

The standard laboratory instrument used to quantitatively measure color is the colorimeter or chromameter. A port on the chromameter is held against the fruit and the reflected light from a flash directed against the fruit is measured and separated into components that represent the lightness to darkness of the color, the hue or shade of color, and the chroma or color purity. The chromameter is very accurate and the measurements very reproducible, but the cost ($9,000 to $10,000) may make it impractical for use outside of a research laboratory.

Credit: Jeffrey K. Brecht, UF/IFAS

Texture: Flesh Firmness and Juiciness or Mealiness

Stonefruit flesh firmness is an important measure of ripeness, and the range and pattern of softening varies widely among the different types of stonefruits as well as among different cultivars of the same type of fruit. This is especially true for peaches, which include cultivars with a number of different genes controlling flesh texture. For Florida peaches, the important distinction is between the traditional melting-flesh cultivars and the newer non-melting-flesh cultivars. Both types are equally firm before they begin to ripen, but melting peaches soften very rapidly during ripening and become extremely soft while non-melting-flesh fruit largely retain their firmness for the first one-third or so of their ripening then soften slowly and never become quite as soft as the melting-flesh fruit.

Fruit juiciness is a desirable quality feature for all types of stonefruits. Lack of juiciness is often called “mealiness,” referring to the dry mouthfeel that reminds people of a mouthful of corn meal. Mealiness is actually the result of abnormal softening in which the fruit cell walls do not break down properly, trapping the liquid in a complex with pectin (the same pectin used to make jams and jellies set up). Mealiness is associated with the chilling injury-related disorder called “internal breakdown.”

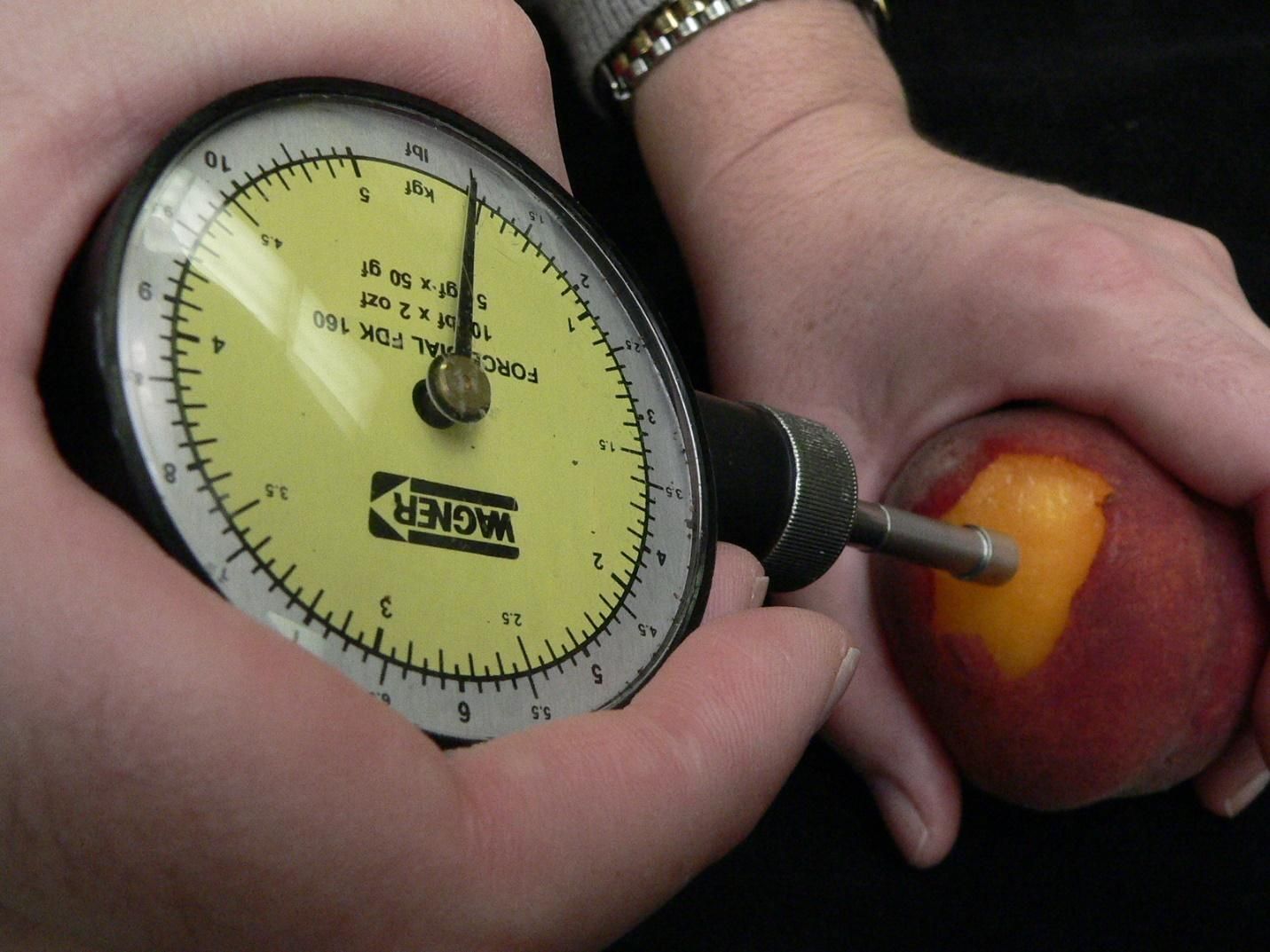

Firmness can be judged by squeezing the fruit. With experience, this can be somewhat accurate, especially for softer fruit. Harvesters should lightly depress the blossom end of fruit with their thumb while grasping the whole fruit in their hand in order to judge whether or not to detach it.

A more accurate and repeatable, and therefore more reliable, method for measuring fruit firmness is to use a penetrometer. A penetrometer is used to push a convex-tipped probe against the flesh of the fruit (peel removed) until the tissue can no longer resist the force being applied and fails, allowing the probe to penetrate the flesh. The force that is recorded is called the “bioyield point.” The probe is connected by a spring to a force gauge that shows firmness on a pounds-force or kilogram-force scale. The diameter of the probe affects the reading (a wider probe gives a higher reading); for stonefruit, a 5/16-inch or 8-mm diameter probe is the correct size. It’s important to remove a small patch of peel before measuring firmness with a penetrometer. This is because, as the fruit softens, the peel can eventually become a greater barrier to penetration of the probe than the underlying flesh, resulting in inaccurate measurements.

Credit: Jeffrey K. Brecht, UF/IFAS

Hand-held penetrometers are most common, but various other types have been developed that mount the probe and force gauge in different ways in attempts to reduce operator variability. More advanced types of texture analyzers are motorized to completely remove operator variability and are connected to a computer so that the texture profile as the probe penetrates the flesh can also be recorded.

Taste and Aroma (Flavor): Soluble Solids and Acidity

The flavor of stonefruits is due to unique combinations of taste and aroma. The taste is primarily a product of the sugars and organic acids that are present, while the aroma comes from our perception of a complex array of volatile compounds produced by the fruit.

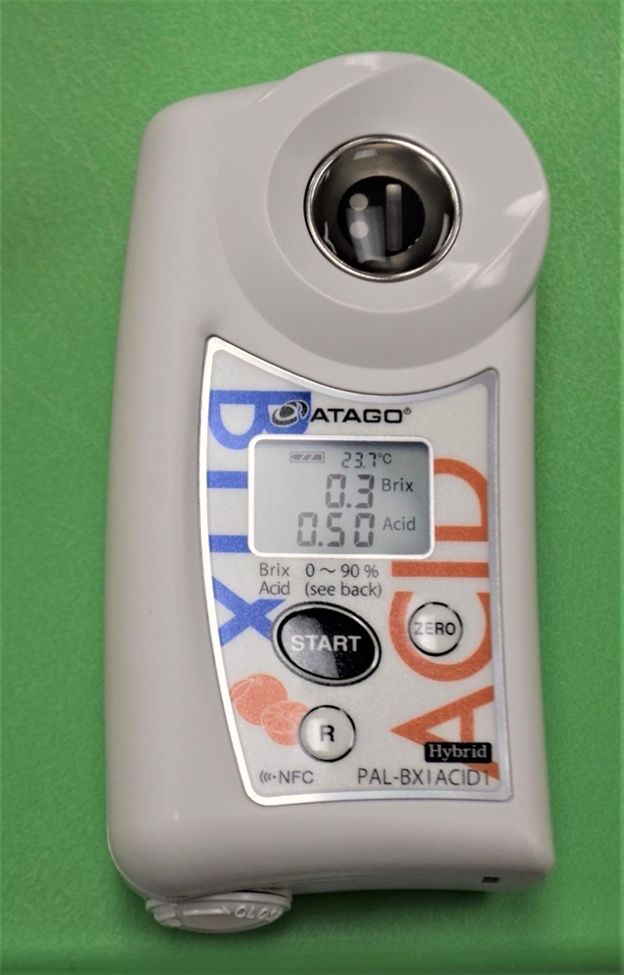

The main method that is used to get at the taste component of stonefruit flavor is to measure the soluble solids content with a refractometer. The refractometer scale is in degrees Brix and is a measure of the refractive index or the degree to which light is refracted or bent by soluble compounds as it passes through a prism. The temperature of the solution affects the refractive index (solutions expand and become less dense as temperature rises); for sugar solutions, the change is about 0.5 degrees Brix per 10 °F (-12 °C). Better-quality refractometers have built-in temperature compensation. Otherwise, the temperature needs to be measured and a correction made before recording the result.

The Brix measurement is made by taking a few drops of juice that have been expressed from the fruit tissue and placing them on the refractometer prism; the refractometer is then held up to the light and the degrees Brix read from a scale. Digital refractometers are also widely available that do not have to be held to the light and that present the result on an LED readout. Refractometers can be calibrated using distilled water (0 degrees Brix at 68 °F [20 °C]). The juice must be rinsed from the prism and the prism dried with a tissue between measurements.

Credit: Jeffrey K. Brecht, UF/IFAS

The major component of soluble solids in fruit juice is the sugars, so Brix readings are often used as a kind of shorthand for sugar content or sweetness. However, other compounds in the juice, such as organic acids, amino acids, phenolics, and soluble pectins, also contribute to the Brix reading.

Fruit acidity is not measured as commonly as soluble solids content, not because it is less important to taste, but because it is less convenient to measure. Until recently, acidity has been measured by titrating a juice sample with a basic solution (usually 0.1 N sodium hydroxide) to an end point of pH 8.2 that is determined either by a pH meter or by the color change of phenolphthalein dye compound. The percent acidity is then calculated using one of three formulas based on whether the predominate acid in the fruit being measured is citric, malic or tartaric acid (note: it is malic acid for stonefruits).

The formula for determining percent titratable acidity from milliliters of 0.1 N sodium hydroxide required to change the juice pH to 8.2 is,

percent acid = [mL NaOH used] X [0.1 N NaOH] X [milliequivalent factor of 0.067 for malic acid] X 100 / grams of juice in sample

This is obviously a laboratory procedure that most producers and handlers don’t care to undertake on a routine basis. However, recently, portable digital acidity meters have become available that are operated very much like a digital refractometer.

Credit: Mark A. Ritenour, UF/IFAS

Taste panels and consumer testing can be useful to determine, in the first case, if there is a flavor difference that can be perceived, and in the second, what consumers like and don’t like about different fruit. Important information about appearance, texture and flavor can be obtained from taste panels and consumer tests, for example, on acceptability prior to introducing a new cultivar, or to determine how harvest maturity affects consumer preference for the ultimate ripe fruit. Methods for conducting taste panels and consumer tests are available from various sources, and there are also companies that specialize in conducting such tests.

Credit: Jeffrey K. Brecht, UF/IFAS

Nutritive Value: Vitamins and Minerals

Stonefruits are an abundant source of ascorbic acid or vitamin C, but the vitamin can be easily lost in fruit that suffer temperature abuse or other kinds of stress. The yellow to orange pigments in stonefruits are carotenoids, which are nutritionally important as antioxidants in our diet and include beta-carotene, also known as pro-vitamin A. Stonefruit also contain another class of antioxidants called phenolics. The phenolics in stonefruit may be red (like the blush on the peel) or colorless. The methods used to measure vitamin C, vitamin A, carotenoids, and phenolics involve fairly sophisticated laboratory procedures and instrumentation that are not practical for producers or handlers. However, service labs will measure these compounds if you wish to include them on Nutrition Facts labeling.

Paying attention to stonefruit quality starts with cultivar selection (Chapter 3) and includes using horticultural practices that promote production of good quality fruit. Careful harvesting and postharvest handling practices (Chapters 5 and 6) reduce physical injuries that lower stonefruit grades. It is important to take steps to minimize chances for decay (Chapter 7) and for contamination and proliferation of microorganisms that endanger food safety (Chapter 8). Rapid cooling to and handling at safe temperatures that do not cause internal breakdown along with proper humidity control to avoid shriveling (Chapter 9) help maintain good quality. Finally, proper ripening practices (Chapter 4) result in the best flavor, increased customer satisfaction, and greater sales.

Additional Reading

Central Valley Postharvest Newsletter. 2008. Vol. 17, No. 2. http://ucanr.edu/datastoreFiles/234-2059.pdf (Contains detailed descriptions of procedures for measuring 1) pH and titratable acidity, 2) fruit firmness, and 3) internal breakdown and soluble solids content.) Crisosto, C. H., F. G. Mitchell, and Scott Johnson. 1995. “Factors in Fresh Market Stone Fruit Quality.” Postharvest News and Information 6 (2): 17N–21N.

Kader, A. A. 2008. “Flavor Quality of Fruits and Vegetables.” Journal of the Science of Food and Agriculture 88:1863–1868. https://doi.org/10.1002/jsfa.3293

Mitcham, E. A., M. Cantwell, and A. Kader. 1996. “Methods for Determining Quality of Fresh Commodities.” UC Davis Perishables Handling Newsletter Issue No. 85. 5 p. (updated 2003) http://ucce.ucdavis.edu/files/datastore/234-49.pdf

United States Dept. of Agriculture, Agricultural Marketing Service. Fresh Market Fruit Grade Standards. http://www.ams.usda.gov/AMSv1.0/freshmarketfruitstandards (standards for apricots, cherries, nectarines, peaches, and plums, along with handbooks and visual aids for inspectors for cherries and peaches).

3. Stonefruit Cultivars for Florida

Ali Sarkhosh, Mercy A. Olmstead, and Jose X. Chaparro

One of the most important decisions taken by a grower is to ensure that a chosen cultivar is adapted to a particular site. Particular peach cultivars destined for commercial production are recommended for each area in order to ensure that the cultivars’ chilling unit requirements will be met in most years. Cultivars with higher chill unit requirements can be grown, but their required chill units will not accumulate every year, which will result in inconsistent cropping.

Cultivars adapted to Florida have been developed by two programs. The Stonefruit Breeding Program operated by the University of Florida Institute of Food and Agricultural Sciences (UF/IFAS) has focused on breeding cultivars with chilling requirements ranging from approximately 100 to 450 chill hours. A second cooperative breeding program located at the Attapulgus Research and Education Center involving scientists from UF/IFAS, the University of Georgia (UGA) and the USDA-ARS in Byron, Georgia has focused on breeding peaches with chilling requirements ranging from 350 to 650 chill hours.

A major focus of the UF/IFAS Stonefruit Breeding Program has been the development of non-melting texture cultivars that can be harvested tree ripe. The non-melting texture cultivars ’UFGold’, ‘UF2000’, ‘UFO’, ‘UFBest’, ‘UFSharp’, ‘UFBlaze’, ‘UFBeauty’, ‘UFGlo’, ‘UFSun’, and 'UFOne' have been released. In addition, the non-melting texture nectarine cultivars ‘UFQueen’ and 'UFRoyal', have been released from the UF/IFAS program. For growers in northern Florida and southern Georgia, the cooperative effort has released ‘Gulfprince’, ‘Gulfking’, ‘Gulfcrest’, and ‘Gulfcrimson’ peaches, which require a higher chilling unit accumulation (350–525 chill units). Today, these and other cultivars released by the UF/IFAS Stonefruit Breeding Program are grown in Australia, Spain, Morocco, South Africa, and around the world.

Most peaches grown for fresh fruit consumption are soft when ripe and are said to have melting texture. The UF/IFAS program focuses on breeding of non-melting texture peaches that are firm even when ripe. Non-melting texture peaches are typically clingstone. The term clingstone refers to the texture adhering to the pit making the pit difficult to extract from the flesh when the peach is sliced in half. It appears that the enzymes involved in softening the texture are also involved in facilitating the separation of the flesh from the pit (Bailey and French 1949; Crisosto 2002). Although there is some variation in the degree of flesh adherence (e.g., semi-freestone or semi-clingstone), non-melting texture, freestone peaches are not currently available.

Commercial Peach and Nectarine Cultivars for Northern and North-Central Florida

‘Flordabest’—250 Chill Units

‘Flordabest’ peach was released and patented by UF/IFAS in 2009 and has a fruit development period (FDP) of 82 days from fruit set to harvest. The fruit develop 90%–100% blush, making them very attractive. The fruit are large and have melting, but uniformly firm, yellow flesh, and semi-clingstone pits. The fruit ripen about 7–10 days earlier than the standard peach cultivar ‘TropicBeauty’ in Gainesville, Florida. It is recommended for trial in Gainesville and south to Interstate 4 (Figure 3-1).

Credit: UF/IFAS

‘UFO’—250 Chill Units

‘UFO’ is a non-melting-flesh, peento type peach. Peento peaches have a unique “doughnut” shape. It was released and patented by UF/IFAS in 2002 and produces large, vigorous trees with a semi-upright growth habit. ‘UFO’ produces moderately heavy crop loads of large, firm fruit with a yellow flesh and semi-freestone pits that have an FDP of 95 days. The skin develops 50%–70% blush. This cultivar is particularly susceptible to ethylene, a stress hormone that is released during dormant pruning, and that can result in significant flower bud abortion. Thus, pruning is not recommended except during the summer period (Figure 3-2).

Credit: UF/IFAS

‘Gulfking’—350 Chill Units

‘Gulfking’ is a non-melting-flesh peach cultivar that was released and patented by the joint UF/IFAS, UGA, and USDA-ARS breeding program in 2004 (Krewer et al. 2005). The fruit have exceptional color, with 80%–90% red skin with stripes over a deep yellow ground color. The fruit are also very firm with yellow flesh and are clingstone. The FDP is 77 days, and the fruit develop good size, shape, and color in northern Florida (Figure 3-3).

Credit: UF/IFAS

‘Gulfsnow’—400 Chill Units

‘Gulfsnow’ peach is a 2012 joint release from the UF/IFAS, UGA, and USDA-ARS breeding program. Trees of ‘Gulfsnow’ are vigorous and semi-spreading, producing white, non-melting-flesh fruit. ‘Gulfsnow’ fruit are large, round, and attractive with a 50%–60% blush over a cream background. The fruit are clingstone, with medium-sized, red pits, and have an FDP of 110 days (Figure 3-4).

Credit: UF/IFAS

‘Gulfcrimson’—400 Chill Units

‘Gulfcrimson’ is the third in a series of peach cultivars released and patented by the joint UF/IFAS, UGA, and USDA-ARS Stonefruit Breeding Program, specifically in 2009 (Krewer et al. 2008). ‘Gulfcrimson’ fruit are large for an early-ripening cultivar and have a yellow ground color with 80%–90% red skin. ‘Gulfcrimson’ ripens with the standard peach cultivar ‘JuneGold’ in Attapulgus, Georgia, with an FDP of 95 days and highly consistent cropping, making it a good mid-season replacement for ‘JuneGold’. It also crops reliably in northern Florida (Figure 3-5).

Credit: USDA-ARS

‘UFGlo’—400 Chill Units

‘UFGlo’ is a white-flesh, non-melting peach that was released in 2009. ‘UFGlo’ fruit are large, develop 80%–90% blush over the entire fruit, and are clingstone. The FDP is 80–85 days. ‘UFGlo’ ripens in areas where the standard cultivar ‘Flordaking’ does well, and it complements ‘UFSharp’ peaches in north-central Florida. It produces consistent crops with good yields in northern Florida (Figure 3-6).

Credit: UF/IFAS

‘GulfAtlas’—400 Chill Units

‘GulfAtlas’ peach is a 2014 release from the UF/IFAS, UGA, and USDA ARS joint breeding program. It is a late-season cultivar, with an FDP of 120 days. The fruit have non-melting flesh with clingstone pits and bright yellow flesh. Fruit are very large and round and ripen about 3 weeks after ‘Gulfcrimson’. Ripe fruit have a 75% blush with some red pigmentation in the flesh under the skin. Trees are vigorous and semi-spreading with few blind nodes and good fruit set. ‘GulfAtlas’ is adapted to an area south of Attapulgus, Georgia, to Gainesville, Florida (Figure 3-7).

Credit: USDA-ARS

‘Gulfcrest’—525 Chill Units

‘Gulfcrest’ peach is a 2004 release from the UF/IFAS, UGA and USDA-ARS joint breeding program. It has an FDP of 62–75 days, and the fruit have non-melting flesh with clingstone pits. Ripe ‘Gulfcrest’ fruit have 90%–95% red color over a deep yellow to orange ground color and ripen in early to mid-May in southern Georgia. ‘Gulfcrest’ fruit can be variable in size on the tree. ‘Gulfcrest’ can produce “twiggy” branch growth. ‘Gulfcrest’ is adapted to extreme northern Florida and southern Georgia (Figure 3-8).

Credit: USDA-ARS

‘Sunbest’—225 Chill Units

‘Sunbest’, released in 2001, is a patented nectarine cultivar with yellow, melting flesh and a semi-freestone pit. It develops 90%–100% bright red blush over a yellow ground color and has a FDP of 85–90 days. ‘Sunbest’ fruit ripen in early May in Gainesville, Florida, about 3 days before the standard ‘Sunraycer’ nectarine cultivar. It is superior to and a good replacement for ‘Sunraycer’ nectarine (Figure 3-9).

Credit: UF/IFAS

‘UFRoyal’—250 Chill Units

‘UFRoyal’ is a yellow flesh, non-melting nectarine with an FDP of 85 days. ‘UFRoyal’ fruit are large, with 100% red skin and semi-clingstone pits. Fruit are symmetrically oval, and in Gainesville, Florida, they ripen approximately 1 week before ‘UFQueen’ (below), in early May. ‘UFRoyal’ fruit have excellent firmness and flavor with excellent shipping potential (Figure 3-10).

Credit: UF/IFAS

‘UFQueen’—250 Chill Units

‘UFQueen’ nectarine is a regular bearer of early, large fruit in north-central Florida, with an FDP of 95 days. ‘UFQueen’ trees are semi-upright and are easily pruned to an open vase system. The fruit have non-melting flesh with clingstone pits and yellow flesh color. The fruit are slightly oval with a slight tip and develop 80%–100% red skin over a yellow background. ‘UFQueen’ fruit ripen about 1 week after the standard ‘Sunraycer’ nectarine cultivar in mid-May in Gainesville, Florida (Figure 3-11).

Credit: UF/IFAS

Commercial Peach Cultivars for Central and South-Central Florida

‘UFSun’—100 Chill Units

‘UFSun’ is a non-melting-flesh peach cultivar released in 2004 (Rouse et al. 2004). ‘UFSun’ trees bear heavy annual crops of early-season, medium-sized fruit with yellow flesh and clingstone pits. ‘UFSun’ fruit are uniformly symmetrical and develop 50%–60% red skin with darker red stripes. ‘UFSun’ fruit ripen with those of the standard peach cultivar ‘Flordaprince’ at Immokalee and Gainesville, Florida, with an FDP of 80 days (Figure 3-12).

Credit: UF/IFAS

‘UFBest’—100 Chill Units

‘UFBest’, released by the UF/IFAS breeding program in 2012, is a non-melting-flesh peach cultivar that produces heavy annual crops of large fruit. ‘UFBest’ fruit develop 95%–100% red skin over a yellow ground color, and the flesh is yellow with clingstone pits. ‘UFBest’ fruit ripen 1 week earlier than ‘UFSun’ (mid-April) in Gainesville, Florida, with an FDP of 85 days (Figure 3-13).

Credit: UF/IFAS

‘TropicBeauty’—150 Chill Units

‘TropicBeauty’ is a non-patented peach cultivar released jointly by UF/IFAS and Texas A&M in 1989. The medium-sized, semi-freestone fruit have yellow, melting flesh and develop 70% blush over a yellow ground color. ‘TropicBeauty’ fruit ripen between ‘UFSun’ and ‘UFOne’ and have an FDP of 89 days (Figure 3-14).

Credit: UF/IFAS

‘UFGem’—175 Chill Units

‘UFGem’ was released in 2013 and is a good candidate for the northern part of central Florida. It is a commercial peach cultivar with near 100% blush, average fruit size of 2.5-inch diameter, and symmetrical fruit shape. It is a clingstone peach with non-melting, yellow flesh, and firm texture. The average FDP is 83 days and ‘UFGem’ sets fruit well when minimum nighttime temperatures are above 57 °F (14 °C) (Figure 3-15).

Credit: UF/IFAS

‘UFBeauty’—200 Chill Units

‘UFBeauty’ is a peach cultivar released in 2002 with fruit that have non-melting flesh, clingstone pits, and very symmetrical shape. The flesh of ‘UFBeauty’ fruit is yellow and very firm, and the skin color is near 100% red, with darker red stripes. ‘UFBeauty’ fruit ripen 3 to 4 days after ‘UFGold’ in Gainesville, Florida, with an FDP of 82 days. Cropping of ‘UFBeauty’ has been unreliable in southern Florida when night temperatures during the bloom period are higher than 57 °F (14 °C) (Figure 3-16).

Credit: UF/IFAS

‘UFOne’—250 Chill Units

‘UFOne’ is a non-melting-flesh peach cultivar released by UF/IFAS in 2008. ‘UFOne’ fruit are medium-large, and the trees regularly bear large crops of marketable fruit. ‘UFOne’ fruit are very firm with yellow flesh and semi-clingstone pits and develop 40% red blush over a yellow ground color. ‘UFOne’ fruit have a fairly long FDP of 95 days and ripen with ‘UFBeauty’ (early May) in Gainesville, Florida (Figure 3-17).

Credit: UF/IFAS

Backyard Peach and Nectarine Cultivars for Northern, North-Central, and Central Florida

‘Flordaking’—450 Chill Units

‘Flordaking’ is an older peach cultivar released by UF/IFAS in 1978. It is not patented and is a good selection for backyard production, with large fruit for a mid-season peach cultivar and moderate resistance to bacterial spot. Fruit of ‘Flordaking’ have yellow, melting flesh, and clingstone pits. ‘Flordaking’ fruit develop 70% red blush over a yellow ground color. ‘Flordaking’ has an FDP of 65–70 days and ripens in early May in Gainesville, Florida. One disadvantage of ‘Flordaking’ fruit is high incidence of split pits when crop loads are low (Figure 3-18).

Credit: UF/IFAS

‘Gulfprince’—400 Chill Units

‘Gulfprince’ peach was jointly released by UF/IFAS, UGA, and USDA-ARS in 2002. Trees of ‘Gulfprince’ are large and vigorous with a spreading growth habit. ‘Gulfprince’ fruit are uniform and symmetrical and develop 45%–55% solid red skin. Fruit have non-melting, and yellow flesh with clingstone pits. ‘Gulfprince’ fruit have exhibited some slight browning due to oxidation on soft, ripe fruit. The FDP is 110 days (Figure 3-19).

Credit: USDA-ARS

‘Suncoast’—375 Chill Units

‘Suncoast’ is a non-patented melting-flesh nectarine cultivar released by UF/IFAS in 1995. ‘Suncoast’ trees are vigorous and semi-spreading. Fruit of ‘Suncoast’ have yellow flesh, develop 80%–90% red blush over a yellow ground color, and are semi-clingstone. ‘Suncoast’ fruit are slightly oblong with no sharp tips or bulges and tend to be tart. ‘Suncoast’ leaves and fruit are resistant to bacterial spot. The FDP of ‘Suncoast’ fruit is 77 days, and the fruit ripen in late April to early May in Gainesville, Florida (Figure 3-20).

Credit: UF/IFAS

‘Flordacrest’—350 Chill Units

‘Flordacrest’ is a melting-flesh semi-clingstone peach cultivar released by UF/IFAS in 1988. ‘Flordacrest’ trees are vigorous with a spreading habit. ‘Flordacrest’ fruit have yellow flesh and develop 60%–80% red blush over a bright yellow ground color. It is the best melting-flesh peach currently available for northern Florida. It ripens after ‘Flordaking’ in northern Florida, in early May in Gainesville, Florida, with an FDP of 75 days (Figure 3-21).

Credit: UF/IFAS

‘UFSharp’—325 Chill Units

‘UFSharp’ is a patented, non-melting-flesh clingstone peach cultivar that was released by UF/IFAS in 2006. ‘UFSharp’ trees are vigorous, semi-spreading in nature, and productive. ‘UFSharp’ fruit develop 60% red blush over a deep yellow to orange ground color. ‘UFSharp’ has reliable cropping with excellent fruit size, shape, and firmness, and an FDP of 105 days (Figure 3-22).

Credit: UF/IFAS

‘UF2000’—300 Chill Units

‘UF2000’ is a yellow-flesh, non-melting, clingstone peach, released in 2000. Trees are highly vigorous with a semi-spreading growth habit and produce heavy annual crops of moderately large fruit. ‘UF2000’ fruit are symmetrically shaped and develop 50%–70% solid red skin over a yellow background. ‘UF2000’ fruit ripen mid-season, with harvest occurring from 15–18 days before ‘UFGold’ in mid-late May in Gainesville, Florida (Figure 3-23).

Credit: UF/IFAS

‘UFBlaze’—300 Chill Units

‘UFBlaze’ is a non-melting-flesh, clingstone peach cultivar released in 2002. Trees are highly vigorous with a semi-spreading nature. ‘UFBlaze’ trees produce heavy annual crops of large, early-ripening, attractive fruit with bright red skin over 80%–90% of a bright yellow-orange background and yellow flesh. Fruit are uniform and symmetrical, and they ripen about 7 to 10 days after ‘UFGold’ in early to mid-May in Gainesville, Florida, with an FDP of 83 days (Figure 3-24).

Credit: UF/IFAS

‘Flordadawn’—300 Chill Units

‘Flordadawn’ is a melting-flesh non-patented peach cultivar released by UF/IFAS in 1989. ‘Flordadawn’ trees are vigorous and produce large numbers of flowers with a moderately high fruit set. The bloom period of ‘Flordadawn’ is extended, which can help with fruit set during early spring frosts. The FDP of ‘Flordadawn’ is 60 days, which is the shortest of any named peach cultivar. Fruit of ‘Flordadawn’ develop 80% red blush and have yellow flesh with semi-clingstone pits. However, light crop loads have resulted in as much as 50% split pit incidence. ‘Flordadawn’ can often be found in large stores and nurseries for backyard plantings (Figure 3-25).

Credit: UF/IFAS

‘Sunmist’—300 Chill Units

‘Sunmist’ is a patented melting-flesh nectarine cultivar released by UF/IFAS in 1994. ‘Sunmist’ trees are highly vigorous and have a spreading growth habit. Fruit of ‘Sunmist’ have white flesh, are semi-freestone, and are large for an early-ripening cultivar. Fruit develop nearly 100% red blush and are uniformly symmetrical. ‘Sunmist’ trees and fruit are highly resistant to bacterial spot. The FDP is 85 days, and the fruit ripen in early May in Gainesville, Florida (Figure 3-26).

Credit: UF/IFAS

‘Sunraycer’—275 Chill Units

‘Sunraycer’ is a non-patented melting-flesh nectarine cultivar released by UF/IFAS in 1993. Trees are vigorous and semi-spreading, responding well to open-center pruning systems. ‘Sunraycer’ produces large, semi-clingstone fruit with good firmness and resistance to bacterial spot. ‘Sunraycer’ fruit develop 80%–100% brilliant red blush over a bright yellow ground color and are oval with no sharp tips or suture bulges. ‘Sunraycer’ has an 85-day FDP and ripens in early May in Gainesville, Florida (Figure 3-27).

Credit: UF/IFAS

‘Sunbest’—225 Chill Units

‘Sunbest’ is a patented melting-flesh nectarine cultivar released by UF/IFAS in 2001. ‘Sunbest’ trees are semi-upright and vigorous, responding well to open-center pruning systems. ‘Sunbest’ fruit develop 90%–100% bright red blush over a yellow ground color, are semi-freestone, and resist bacterial spot well. ‘Sunbest’ is intended as a replacement for ‘Sunraycer’ nectarine because of its larger and more attractive fruit. ‘Sunbest’ has an FDP of 85–90 days, and its fruit ripen approximately 3 days before ‘Sunraycer’ nectarine and ‘Flordaglo’ peach in Gainesville, Florida (Figure 3-28).

Credit: UF/IFAS

Backyard Peach Cultivars for Central and South-Central Florida

‘TropicSnow’—225 Chill Units

‘TropicSnow’ was jointly released by UF/IFAS and Texas A&M in 1989. Its fruit have white, melting-flesh, and semi-freestone pits. ‘TropicSnow’ fruit develop 40%–50% red blush over a creamy white background and have very low acid combined with excellent sweetness. ‘TropicSnow’ has an FDP of 90–97 days in Gainesville, Florida (Figure 3-29).

Credit: UF/IFAS

‘UFGold’—200 Chill Units

‘UFGold’ is a non-melting, yellow-flesh clingstone peach released by UF/IFAS in 1996. ‘UFGold’ trees bear heavy annual crops of large fruit. Fruit are symmetrical and develop 70%–90% blush over an orange-yellow ground color. ‘UFGold’ fruit ripen approximately 80 days after bloom, in early May in Gainesville, Florida (Figure 3-30).

Credit: UF/IFAS

‘Flordaprince’—150 Chill Units

‘Flordaprince’ was released by UF/IFAS in 1982, and its fruit have melting flesh. It has been a standard low-chill peach cultivar worldwide and is one of the earliest-ripening peach cultivars. The fruit develop 80% red blush with dark red stripes over a yellow ground color. ‘Flordaprince’ fruit are large, uniformly firm, and yellow, with semi-clingstone pits. The fruit ripen about 7–10 days earlier than ‘TropicBeauty’ in Gainesville, Florida, with an FDP of 78 days (Figure 3-31).

Credit: UF/IFAS

‘Flordaglo’—150 Chill Units

‘Flordaglo’ is a melting-flesh peach cultivar released by UF/IFAS in 1988. The fruit develop 50%–60% red blush with stripes over a white ground color. ‘Flordaglo’ fruit are early-ripening and semi-clingstone. They are resistant to bacterial spot. ‘Flordaglo’ fruit ripen in early May in Gainesville, Florida, approximately 78 days after full bloom. Due to its melting-flesh fruit texture and the tendency of the fruit to show bruises and abrasions easily, ‘Flordaglo’ fruit are a poor choice for commercial production but are ideal for backyard or u-pick operations (Figure 3-32).

Credit: UF/IFAS

Plum Cultivars Adapted to Northern, North Central, and Northwestern Florida

‘Gulfbeauty’

‘Gulfbeauty’ plum was released in 1998 and patented by UF/IFAS. Its chilling requirement is about 225 hours. Fruit color is dark reddish purple, and the flesh is yellow with a green hue (Figure 3-33). The skin is sour, which is common in Japanese plums, but the flesh is sweet, sub-acid, and firm when ripe. The fruit are clingstone, and the flesh clings to the stone even when soft ripe. Fruit are round and medium-sized (1¾ inch in diameter) and weigh from 55 to 70 grams. Bloom and cross-pollination occur with all other ‘Gulf’ series plums. Fruit set is good, with flowers formed on spurs and the previous season’s shoots. ‘Gulfbeauty’ is the earliest plum to ripen from the UF/IFAS breeding program, with a fruit developmental period of 75 days in Gainesville, Florida.

Ripening occurs about 5 days before ‘Gulfruby’ and about 8–12 days before ‘Gulfblaze.’ As the fruit approach full ripe, their color becomes noticeably darker. Ripe fruit will hang on the tree for 7–10 days. Quality is good, especially for an early-ripening plum. During its season, no other fresh plums are available. Trees are vigorous with tall upright shoots and are semi-spreading. In the absence of freezing conditions, thinning is required to obtain adequate size and prevent limb breakage. Trees are very resistant to bacterial canker and moderately resistant to plum leaf scald.

Credit: Paul Miller, UF/IFAS

‘Gulfblaze’

‘Gulfblaze’ plum was released and patented by UF/IFAS in 1997 (Figure 3-34). Fruit ripen in the middle of the Florida plum season. The chilling requirement for ‘Gulfblaze’ is about 250 hours. Bloom and cross-pollination occur with all other ‘Gulf’ series plums. Fruit set is good with flowers formed on spurs and the previous season’s shoots. Fruit are very firm, average in size (1 7/8 to 2 inches in diameter), and weigh 70 to 80 grams. Fruit are round and semi-freestone with flesh weakly attached to the pit when ripe. Fruit color is dark red to purple, and the flesh is orange, sweet, and sub-acid (Figure 34). The skin is sour, although overall fruit quality is good. Fruit ripen 8 to 14 days after ‘Gulfbeauty’ in Gainesville, Florida, with a fruit developmental period of 95 days. Bloom, pollination, fruit set, and ripening characteristics are the same as for ‘Gulfbeauty’. The leaves, stems, and fruit have similar resistance to bacterial canker and plum leaf scald as ‘Gulfbeauty’.

Credit: Mercy A. Olmstead, UF/IFAS

‘Gulfrose’

‘Gulfrose’ was released and patented by UF/IFAS in 2002 and ripens about 1 week later than ‘Gulfblaze’, with a fruit developmental period of 95 days in Gainesville, Florida (Figure 3-35). The chilling requirement is about 275 hours. The fruit are nearly round, semi-freestone, average in size (1 7/8 to 2 inches in diameter), and weigh 70 to 80 grams. The skin is dark reddish purple, and the flesh is blood red in color (Figure 35). Fruit quality is high with good firmness and shelf life. The fruit have a sweet, aromatic flesh and a moderately sour skin. There is none of the bitter aftertaste common in other blood plums such as ‘Mariposa’. Bloom, pollination, fruit set, and ripening qualities are the same as for those of ‘Gulfbeauty’. Trees are moderately vigorous, semi-spreading, and precocious, bearing the second year after planting. ‘Gulfrose’ has similar resistance to bacterial canker as ‘Gulfbeauty’; however, it is less tolerant to plum leaf scald than ‘Gulfblaze’. ‘Gulfrose’ susceptibility to leaf scald is similar to that of ‘Gulfgold’, limiting tree longevity.

Credit: Mercy A. Olmstead, UF/IFAS

‘Gulfruby’

‘Gulfruby’ originated at the UF/IFAS breeding program but was not released by the university because of its susceptibility to bacterial canker. It was first propagated along with ‘Gulfgold’ in 1982 by Grand Island Nursery in Umatilla, Florida. It is not patented and is, therefore, a public cultivar. Bacterial canker readily occurs on leaves and small twigs of ‘Gulfruby’ and is aggravated by frequent summer rains. Generally, the tree may survive from 5 to 8 years and provide several crops of early-ripening plums. Fruit are round, medium-sized, and up to 2 inches in diameter (Figure 3-36). The flesh is sweet, yellow with a greenish tinge, and adheres to the small pit when fruit are soft ripe. Skin color is red to purple with sour characteristics. Fruit will hang on the tree 3–5 days after full red skin color develops. ‘Gulfbeauty’ fruit will ripen 7 to 10 days before ‘Gulfblaze’ in Gainesville, Florida. The tree is not as vigorous as ‘Gulfbeauty’, nor does it possess as much of the strong upright shooting tendencies of ‘Gulfbeauty’. ‘Gulfruby’ has more problems with bacterial canker than the other low-chill cultivars recommended for trial. Bacterial canker can cause cankers on the wood and significant leaf damage leading to defoliation, which can result in sunburn on the fruit due to leaf loss.

Credit: Paul Miller, UF/IFAS

‘Gulfgold’

‘Gulfgold’ is a yellow skin plum, but the fruit develop a red blush as ripening progresses. Fruit flesh is yellow and semi-soft when ripe. Although it was developed by UF/IFAS, it was not patented. Fruit ripen in late May to mid-June in Gainesville, Florida. They are the sweetest of the ‘Gulf’ series. ‘Gulfgold’ is susceptible to plum leaf scald, which generally limits tree life in Florida. Trees are dwarf in growth habit. Bloom is after ‘Gulfruby’ by a few days, and ‘Gulfgold’ will cross-pollinate with the other ‘Gulf’ plums.

Credit: Daleys Fruit. https://www.daleysfruit.com.au/buy/plum-gulfgold-tree.htm

Plum Cultivars Conditionally Recommended for Trial for Northern Florida Due to a Higher Chilling Requirement

Plum cultivars with the Au prefix have been released from the University of Auburn plum breeding program, and ‘Robusto’, ‘Segundo’, and ‘Byrongold’ are from the USDA-ARS Stonefruit Breeding Program in Byron, Georgia. They can cross-pollinate each other. Florida nurseries may sell other cultivars such as ‘Scarlet Beauty’; however, there is no data available on their tree or fruit production characteristics.

‘Au-Homeside’

‘Au-Homeside’ produces a light red plum with amber flesh. Fruit are oval and about 2 1/3 inches in diameter. Fruit are attractive and overall quality is good. Fruit ripen in mid-June and tend to size well before color is achieved. Trees are not vigorous, but ‘Au-Homeside’ is tolerant to plum leaf scald.

‘Au-Producer’

‘Au-Producer’ fruit have dark red skin, and the flesh is also red. Fruit are small, round, and less than 2 inches in diameter. Fruit quality is high, and the fruit ripen in mid-June. Tree vigor is moderate, but trees require heavy thinning. ‘Au-Producer’ is tolerant to plum leaf scald. Chilling requirement is about 750 units.

‘Au-Roadside’

‘Au-Roadside’ produces a magenta fruit with a red flesh color. Fruit are oval and less than 2 inches in diameter. Fruit quality is very good, and fruit ripen in mid-June. Trees are highly vigorous. Fruit tend to be too soft for commercial shipping. ‘Au-Roadside’ is tolerant to plum leaf scald. Chilling requirement is about 750 units.

‘Au-Rosa’

‘Au-Rosa’ produces red fruit with some light-yellow areas. Fruit are round and 2 inches in diameter. Fruit quality is good, and fruit are attractive. Fruit ripen in mid-June. ‘Au-Rosa’ is resistant to plum leaf scald. Chilling requirement is about 750 units.

‘Au-Rubrum’

‘Au-Rubrum’ skin color is maroon and flesh color is red. Fruit are round and 2 inches in diameter. Ripening date is mid-June. Tree vigor is good. ‘Au-Rubrum’ is tolerant to plum leaf scald. Chilling requirement is about 750 units.

‘Byrongold’

‘Byrongold’ produces fruit with yellow skin and flesh. Fruit develop red blush during the latter part of ripening. Fruit are round and approximately 2 inches in diameter. Fruit ripen in late June to early July with good firmness and fruit quality. Trees are highly vigorous but may have some problems with leaf scald. Chilling requirement is about 450 units.

‘Excelsior’

‘Excelsior’ is a native plum discovered by George Tabor of Glen St. Mary’s Nursery and requires approximately 400 chilling units. Both the flesh and fruit skin are yellow. The fruit size is about 2 inches. The flesh is somewhat translucent and watery.

‘Methley’

‘Methley’ is an older cultivar that is no longer recommended because of small fruit size, lack of firmness, and susceptibility to plum leaf scald and other diseases of bacterial origin. It is self-pollinating. Chilling requirement is about 650 units.

‘Robusto’

‘Robusto’ produces a red fruit with yellow flesh and ripens in early June. The tree blooms in early March and requires approximately 400 to 500 chill units.

‘Santa Rosa’

‘Santa Rosa’ produces a purple/red colored fruit with red flesh. Santa Rosa is an older cultivar that is no longer recommended because of susceptibility to plum leaf scald and other diseases of bacterial origin. Chilling requirement is about 650 units.

‘Segundo’

‘Segundo’ is a red plum with yellow flesh that ripens in mid- to late June. The fruit are somewhat soft, and the tree requires approximately 400 to 500 chilling units.

Additional Reading

Bailey, J. S., and A. P. French. 1933. The Inheritance of Certain Characteristics in the Peach.” Proceedings of the American Society for Horticultural Science 29:127–130.

Crisosto, C. H. 2002. “How do we increase peach consumption?” Acta Horticulturae 592:601–605. https://doi.org/10.17660/ActaHortic.2002.592.82

Krewer, G., T. Beckman, J. Chaparro, and W. Sherman, 2005. “‘Gulfking’ and ‘Gulfcrest’, New Peaches for the Lower Coastal Plain.” HortScience 40:882. https://doi.org/10.21273/HORTSCI.40.3.882d

Krewer, G. W., T. G. Beckman, J. X. Chaparro, and W. B. Sherman. 2008. “‘Gulfcrimson’ Peach.” HortScience 43:1596–1597. https://doi.org/10.21273/HORTSCI.43.5.1596

Rouse, R. E., W. B. Sherman, and P. M. Lyrene, 2004. “‘UF-Sun’ Peach.” Journal of the American Pomological Society 58:108–110.

4. Postharvest Physiology of Stonefruits

Mark A. Ritenour and Jeffrey K. Brecht

Introduction

Stonefruits are relatively soft-fleshed and highly perishable (Figure 4-1). Other chapters in this handbook cover some aspects of stonefruit physiology including fruit maturity, quality attributes, and physiological disorders. This chapter will cover physiological aspects of fruit development and postharvest changes related to ripening and softening.

Credit: Mark A. Ritenour, UF/IFAS

Fruit Development

Peach trees bloom early, before there is extensive leaf development, and so initial fruit set is fed by starch reserves stored in the woody tissues from the previous season’s growth. Thus, tree health and carbohydrate reserves from last season’s growth affect the current season’s crop. Fruit development is ultimately fueled by sunlight harvested by the leaves through photosynthesis during the growing season. The ability of fruit to continue development and successfully compete for the limited resources produced by the leaves depends largely on the proximity of fruit to the supplying leaves (leaves preferentially supply fruit closest to them) and the number of fruit vying for the limited resources. When resources are insufficient, fruit may drop (abscise) prematurely or may not obtain desirable sizes. This is why thinning fruit results in larger fruit size.

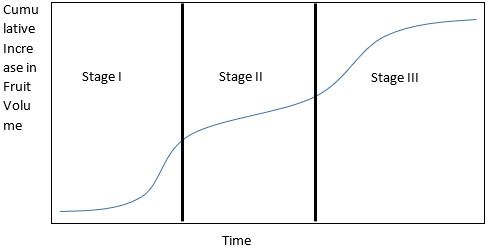

After bloom and successful fruit set, fruit growth goes through three stages:

- Rapid fruit growth from cell division and elongation; the duration of this stage is uniform among cultivars.

- Fruit dry weight increases without much increase in fruit size while imported carbohydrates fuel pit (stony endocarp) development and hardening; the duration of this phase is what determines early-, middle-, and late-season cultivars.

- Fruit enlargement and increase in sugar content in the mesocarp (flesh) before harvest; the fruit can begin to ripen during this stage.

Credit: UF/IFAS

It is important to avoid resource (carbohydrate) limitations throughout the growth period because a lack of carbohydrate at any point during growth can prevent fruit from reaching a desirable size. However, because maximum fruit size is related to the number of cells within the fruit and the first stage of development is the one when cell division occurs, resource limitations during stage I (and especially later in this stage) are of primary concern. Resource limitations during stage I most permanently reduce maximum fruit size. Therefore, fruit thinning, if practiced, should occur before the second half of stage I to reduce resource competition, allowing remaining fruit an adequate supply of resources for maximum cell division. Sugar accumulation within the fruit is most rapid later in fruit development, reaching a maximum just before the onset of the ethylene climacteric (explained below) and ripening. Thus, delaying harvest results in sweeter fruit, but at the risk of the fruit softening to the point that they are easily injured during postharvest handling and marketing.

Fruit Ripening

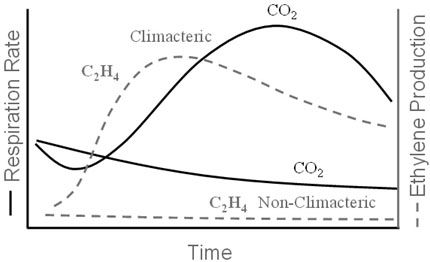

Most stonefruit except cherries and a few plum cultivars are classified as climacteric fruit (Table 4-1) because their respiration rates increase to a peak (the climacteric) during ripening. This increase in respiration is accompanied by an increase in a gaseous plant hormone called ethylene. The magnitude of the respiratory climacteric peak varies depending on the cultivar, but stonefruits are generally considered to have moderate (10–20 mg CO2/kg-hr) respiration rates. Ethylene production among the climacteric stonefruit species is considered high (10–100 µL/kg-hr) when going through their climacteric. Ethylene actually initiates and coordinates the ripening process in these fruits (e.g., softening and characteristic color and aroma development). Once the ripening is underway, this type of fruit can continue to ripen normally whether it remains attached to the plant or not. Other climacteric fruits include apples, avocados, bananas, mangoes, and pears.

The other type of fruit, called “nonclimacteric,” has a declining pattern of respiration during fruit ripening. These fruits produce very little ethylene, with no change in its production rate during ripening. For example, the ethylene production rate of the nonclimacteric cherry is very low: <0.1 µL/kg-hr. Nonclimacteric fruits are not able to ripen normally unless they remain attached to the plant, so they must always be harvested when fully ripe; other examples include citrus, grapes, and strawberries. While ethylene stimulates and coordinates the ripening of climacteric fruits, it plays no role in nonclimacteric fruit ripening. Figure 4-3 illustrates the different patterns of respiration and ethylene production during ripening for climacteric and nonclimacteric fruits.

Exposing unripe climacteric fruits to ethylene in order to stimulate the onset of ripening is a common commercial practice that is used for some climacteric fruits like bananas and tomatoes. However, recent Florida peach cultivars developed by the University of Florida have the “non-melting-flesh” trait, which allows their fruit to be harvested when they are close to fully ripe because they remain quite firm well into the ripening process. Conversion of starch to sugar is an important process during ripening of some climacteric fruits (e.g., apple and banana), but stonefruit generally contain very little starch before ripening; instead, stonefruits continue to accumulate sugar from photosynthesis while ripening on the tree. Thus, harvesting Florida peaches when they are unripe and using ethylene treatment to promote ripening is not necessary and is not a recommended practice. Leaving fruit on trees to ripen is possible now that non-melting-flesh Florida peaches are available. Peaches left to ripen on the tree are of greatly improved quality compared to peaches grown in most other places.

Table 4-1. Examples of different types of stonefruits and their classification as either climacteric or non-climacteric.

Credit: UF/IFAS

Once climacteric fruits are physiologically mature, or when they have achieved nearly their full size, the ripening process is the same whether the fruit remain on the tree or are harvested, including the changes in color, taste, aroma, and flesh texture. This means that climacteric fruits can be harvested when they are mature but unripe, and then the remainder of the ripening can be controlled (slowed) by using rapid cooling and handling at low temperatures to extend shelf life with acceptable quality. However, since peaches continue to accumulate sugar on the tree during ripening, early harvesting results in fruit that are less sweet than tree-ripe fruit. Non-climacteric fruits can only complete ripening on the tree, and non-climacteric fruits harvested prior to full ripeness will never advance beyond their at-harvest ripeness stage, ensuring poor quality.

Stonefruit shelf life is generally between 1 to 5 weeks depending on the type of stonefruit and the cultivar. Climacteric stonefruits that are harvested immature will not ripen to acceptable quality, while those harvested after ripening begins in the orchard may soften too much and become too easily injured during postharvest handling, transportation, and marketing.

Ripening of climacteric fruits harvested mature but unripe can be hastened by postharvest exposure to ethylene if desired, but the natural pace of ripening is usually sufficient, and accelerated ripening often leads to problems during distribution. The optimum temperature range for ripening stonefruits is 68 °F to 72 °F (20 °C to 22 °C) with relative humidity of 90%–95%. Temperatures above 77 °F (25 °C) reduce the rate of ripening, induce off flavors, and promote irregular ripening, while temperatures above 86 °F (30 °C) inhibit ethylene biosynthesis and thus, inhibit ripening. While inhibitors of ethylene action (e.g., methylcyclopropene [MCP]) have been used effectively to delay ripening and extend shelf life in other climacteric commodities such as apple, they are less effective for use with stonefruit. Using ventilation or scrubbing to remove ethylene from the postharvest environment can also slow the ripening of climacteric fruits.

Depending on the cultivar, the use of modified or controlled atmosphere (MA or CA) conditions containing 1%–5% O2 plus up to 5% CO2, or 3%–10% O2 plus 10%–15% CO2 for cherry, can supplement temperature management by further slowing respiration and ethylene production, delaying softening; possibly inhibiting the development of internal breakdown (chilling injury); and extending overall shelf life. However, the benefits of MA and CA are often not substantial, and such atmospheres also can cause fruit to develop off flavors. Thus, there is very limited use of CA or MA for stonefruit. It is used for occasional marine transport and sometimes in combination with pallet wraps for cherries. The most successful strategy to extend the market window of stonefruit has been the development of cultivars that mature at different times so that there is a continuous supply of product coming to maturity over longer periods of the season. This has proven much more successful than developing techniques to store the fruit for extended periods.

Fruit Softening: Melting-Flesh Peaches vs. Non-Melting-Flesh Peaches

Melting-flesh peaches – This is the traditional type of peach. As melting-flesh peaches begin to ripen, there is an initial “softening stage” during which flesh firmness initially decreases slowly; however, this softening eventually becomes rapid (the “melting stage”). Stonefruit softening is related to the work of a number of different cell-wall enzymes that break down pectic and other carbohydrate polymers in the cell walls. The cell walls almost disappear, basically leaving only sacs of juice held together by the fragile remnants of the cell walls.

Non-melting-flesh peaches – Non-melting flesh in peaches is a natural mutation in which one of the most important enzymes involved in the melting stage of fruit softening (endopolygalacturonase) is absent. The first softening stage during which flesh firmness initially decreases slowly is the same as for melting-flesh fruit, but with the final melting stage being largely absent, non-melting peaches retain some firmness when they are fully ripe. The non-melting trait has traditionally been exploited for canning peach cultivars, but the University of Florida Institute of Food and Agricultural Sciences (UF/IFAS) Stonefruit Breeding Program has used it to develop fresh-market cultivars that are more suited for tree-ripe marketing because the ripe fruit remain firm enough for marketing.

Stony hard (hd) peaches – Stonefruit cultivars with this softening trait are characterized by the absence of both ethylene production at ripening and postharvest softening (Ramina et al. 2008). Stony hard is a “slow-ripening” mutant, which means that eventually ethylene will rise, but only to 15%–33% of normal rates. The ripening process in stony hard fruit is slowed sufficiently so that producers are able to harvest partially ripe fruit with a long remaining shelf life. Exposure to ethylene gives a non-climacteric physiological response, meaning that the fruit do not respond by ripening faster.

Additional Reading

Bassi, D., and R. Monet. 2008. “Botany and Taxonomy.” In The Peach: Botany, Production and Uses, edited by Desmond Layne and Daniele Bassi, 1–36. Wallingford, Oxfordshire, GBR: CABI Publishing. https://doi.org/10.1079/9781845933869.0001

Ramina, A., P. Tonutti, and B. McGlasson. 2008. “Ripening, Nutrition and Postharvest Physiology.” In The Peach: Botany, Production and Uses, edited by Desmond Layne and Daniele Bassi, 550–574. Wallingford, Oxfordshire, GBR: CABI Publishing. https://doi.org/10.1079/9781845933869.0550

5. Stonefruit Harvest Operations