Introduction

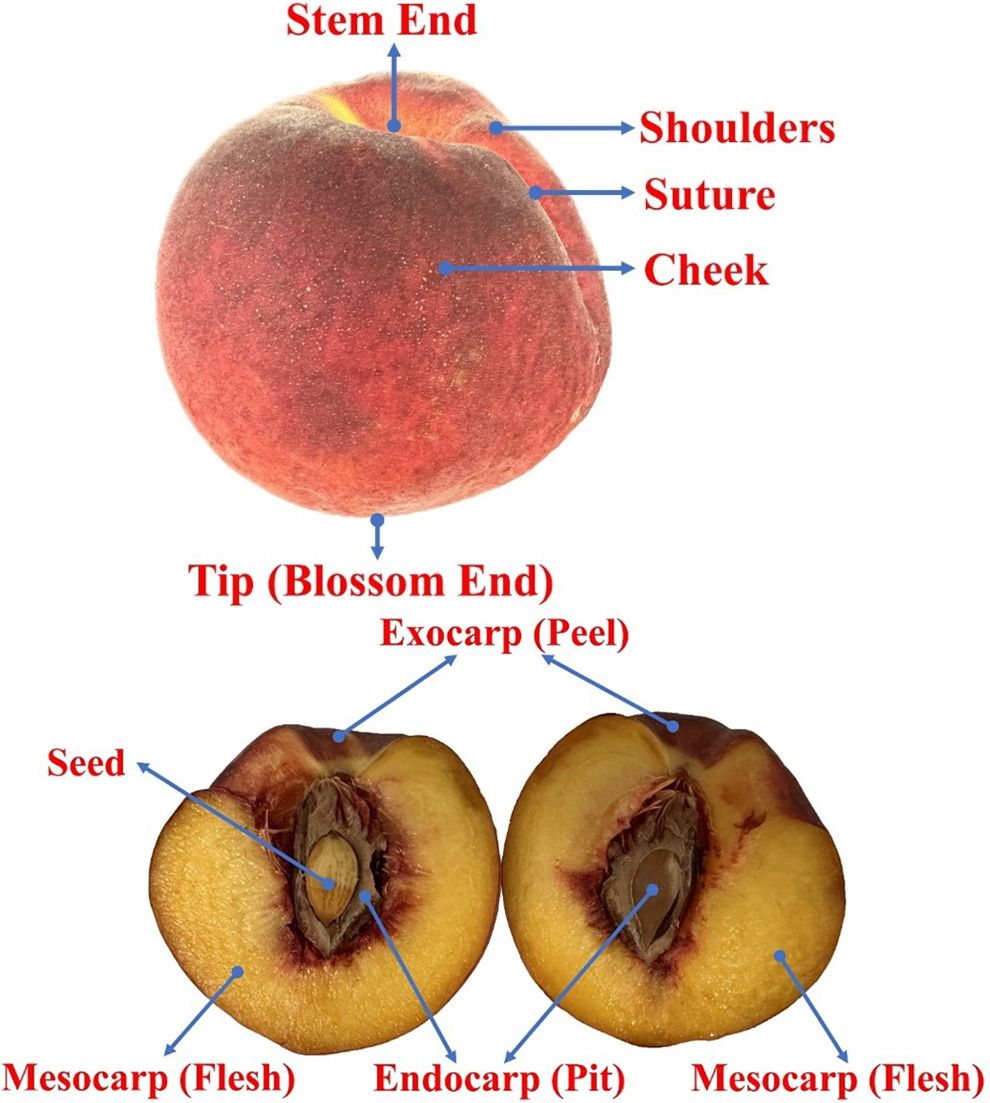

Peach (Prunus persica L. Batsch) (Figures 1 and 2) is a valuable temperate fruit from the Rosaceae family, which also includes many other commercially important fruits such as apples and pears, apricots, cherries and plums, and blackberries, raspberries, and strawberries. Peaches are known for being a rich source of bioactive compounds, including flavonoids, anthocyanins, carotenoids, phenolic compounds, and vitamins, as well as possessing a high antioxidant activity, all of which are associated with various health benefits. Furthermore, consumers greatly value high-quality peaches due to their exceptional nutritional value and enjoyable sensory attributes.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

After harvest, peaches that are not immediately eaten experience some physiological and biochemical changes associated with ripening that can affect their texture, flavor, and overall fruit quality. Peaches are highly perishable fruit, and their postharvest life depends on various factors, including proper handling and storage practices that are essential to maintain quality and extend shelf life. Temperature management is especially important as it involves prompt and rapid cooling and storage at an optimum temperature of 32°F to 34°F (0°C to 1°C) for maximum shelf life. Peach fruit are susceptible to rapid senescence (aging) and decay when kept at room temperature (Figure 3). Immediately after harvest, peaches continue to respire, leading to the consumption of stored carbohydrates and organic acids and the production of carbon dioxide. These processes produce ethylene, which is the ripening hormone for many fruits. If not properly managed, high respiration rates and ethylene production can result in rapid softening, loss of firmness, and overall deterioration of fruit quality.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Furthermore, the accumulation of pigments, including anthocyanins and carotenoids, affects the color development and visual appeal of peaches; changes in these compounds during postharvest storage can impact the fruit’s attractiveness to consumers. It is possible to use some drying methods to extend the availability of peaches throughout the year, regardless of seasonal accessibility. This publication aims to familiarize growers, Extension agents and specialists, and the public with insight into drying methods of peach fruit, including dehydration and freeze-drying, that can extend the shelf life of this commodity for year-round enjoyment.

Dried Peach Products

Advantages of Dried Peach Fruit

While different postharvest treatments including cold storage, edible coating, modified atmosphere packaging (MAP), chemical elicitors, and hot water can be effective in extending the postharvest life of fresh peaches, they have some limitations. These limitations include the need for specialized facilities and equipment for low temperatures and controlled humidity, potential heat damage and tissue softening, loss of texture, and challenges in effectively controlling microbial growth and preventing residue accumulation of chemical elicitors. However, dried peach products, including freeze-dried and dehydrated peaches, offer a relatively easier and longer-lasting alternative with extended shelf life and reduced reliance on these challenging postharvest treatments.

Dried peach fruit have several benefits over postharvest techniques for extending the shelf life of fresh peaches. First, the drying process removes a significant portion of the fruit’s moisture content (80% to 85%), practically eliminating the risk of decay and substantially prolonging the shelf life of the fruit compared to fresh peaches. The percentage of moisture content removed by the drying process depends on the type of fruit, the drying method, and the desired final moisture content. However, the drying process can remove up to 85% of the moisture content of the fruit. Therefore, dried peaches are a more convenient and practical option for storage and transportation under ambient temperatures. Moreover, dried peaches are lightweight and occupy less volume than fresh peaches, facilitating easier packaging, storage, and shipping (Figure 4). This can help reduce transportation costs and minimize the probability of physical damage during handling. Dried peaches also retain their nutritional content, comprised of vitamins, minerals, and dietary fiber, rendering them a healthy and suitable snack option. Some drying methods also better preserve the original flavors and aromas, resulting in an intensified taste experience that can be enjoyed throughout the year, irrespective of seasonal availability. Moreover, dried peaches offer versatility and can be utilized in various culinary endeavors, including baking, cooking, and snacking. They can be incorporated into recipes, used as toppings, or enjoyed independently as a stand-alone snack. Different drying methods, including traditional methods and advanced technologies like freeze-drying and dehydration, can be used effectively for drying fruits. A comprehensive survey of traditional drying methods, as well as modern techniques including freeze-drying and dehydration technologies, will provide valuable insights into their advantageous and disadvantageous aspects as well as identify their strengths and limitations in the context of dried peach fruit.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Disadvantages of Traditional Drying Methods

Traditional drying methods have been employed to preserve fruit shelf life and create tasty, long-lasting snacks. The most common traditional drying method is solar drying, whereby fruit are spread out under the sun to naturally dry over an extended period of at least several days. Another method is air drying, which involves exposing fruit to circulating, naturally dry, ambient air to gradually remove moisture.

Traditional drying methods are cost-effective, requiring minimal investment in equipment and technology. They are also natural and sustainable, utilizing sunlight and air circulation. While these methods have their advantages, they also come with certain disadvantages. One significant disadvantage is their dependence on weather conditions. For example, sun drying is strictly dependent on sunlight and warm temperatures, making it unsuitable for regions with inconsistent weather patterns or high humidity. Also, air drying can be slow and time-consuming, often taking several days or weeks to achieve the desired moisture content. This prolonged drying time raises the risk of microbial contamination and spoilage. Another disadvantage of traditional methods is the lack of control over such factors as temperature, humidity, and airflow, leading to variations in the drying process and potentially uneven drying results. Inadequate drying can result in fruit that is overly dry, tough, or prone to mold growth, compromising its quality and taste. In addition, traditional drying methods may not effectively preserve the original color, flavor, and nutritional value of the fruit. Prolonged exposure to sunlight or air can lead to nutrient loss, degradation of natural pigments, and flavor changes. These methods may not guarantee consistent and uniform drying throughout the fruit, leading to variations in texture and taste. Moreover, traditional drying methods often require extensive space and can be labor-intensive. The process of spreading out fruit under the sun or in well-ventilated areas demands sufficient drying surfaces, which may not be practical for large-scale operations. Furthermore, constant monitoring and manual handling (turning) of the fruit are necessary to promote even drying, which can be time-consuming and physically demanding. Protection from contaminants, pests, and human pathogens is also necessary.

While traditional drying methods have their cultural and historical significance, they present limitations in terms of weather dependence, control over drying parameters, preservation of quality, and labor requirements. Modern drying techniques, such as dehydration and freeze-drying technologies, have emerged to address these disadvantages and provide more efficient and consistent drying results for different fruits.

Dehydration Technology and Its Advantages and Disadvantages

Dehydration of fruit refers to the application of heat, usually heated air, to evaporate water from fruit, as opposed to traditional drying as described in the previous section. Dehydration technology offers several advantages for peach fruit preservation and consumption. Dehydration quickly dries fruit and significantly prolongs shelf life by removing moisture, inhibiting the growth of microorganisms and preserving nutritional content. Dehydrated fruits are compact, lightweight, and convenient for storage and transportation. Dehydration also preserves intense flavor, making it a pleasing addition to various dishes and snacks.

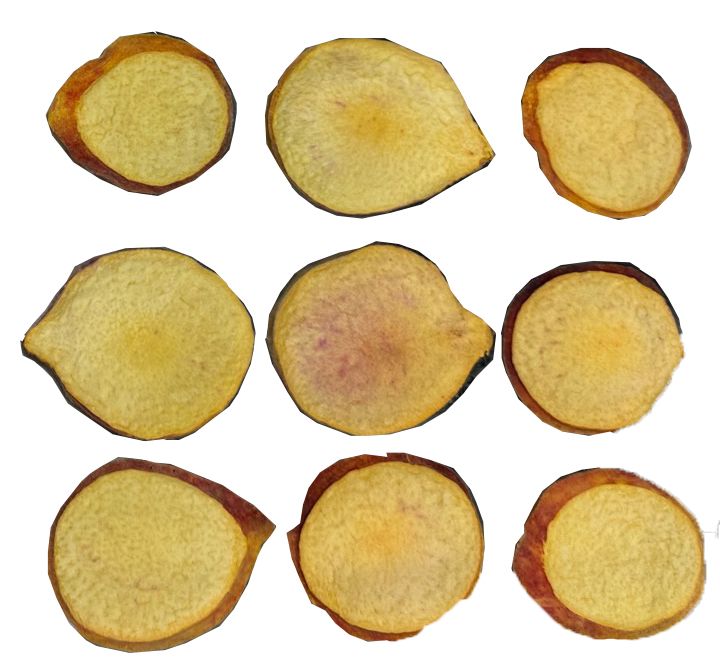

However, dehydration technology has some disadvantages to consider. Dehydration can result in texture changes and a loss of freshness compared to fresh peaches (Figure 5). The initial cost of dehydration equipment and energy consumption can be expensive and must be considered, especially for commercial-scale operations. The dehydration process also requires time and planning, especially for large quantities of fruit with high moisture content. Evaluating these advantages and disadvantages helps in making informed decisions about the use of dehydration technology for preserving and enjoying peach fruit.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

The Mechanism of the Dehydration Method

The mechanism of a fruit dehydrator involves a series of steps to effectively remove water from the fruit to the desired level of dehydration. First, the dehydrator is equipped with heating elements, typically electric, that generate the appropriate temperature for the drying process. The washed and sliced peaches are placed on trays or racks inside the machine, allowing proper spacing for air circulation. The dehydrator incorporates a fan or airflow system that circulates heated air within the drying chamber, accelerating moisture removal from the peach slices or halves. Temperature and time controls are necessary features of the dehydrator. The optimal temperature ranges from 122°F to 158°F (50°C to 70°C), depending on the type of fruit, therefore promoting effective moisture removal without causing excessive heat damage to the fruit. The duration of the drying process varies depending on the thickness of the peach slices and the desired level of dehydration. The dehydrator also includes air vents or adjustable vents to control the airflow and moisture release during the drying process. These vents allow excess moisture to escape while maintaining a controlled environment inside the machine. During the dehydration process, the unit constantly monitors the temperature and airflow to manage optimal conditions. Some advanced dehydrator models may offer additional features such as timers and automatic shut-off functions. Once the peaches have reached the desired moisture content, typically 10% to 20%, the drying process is complete. The dehydrated peach fruit can then be removed from the machine and allowed to cool before storage. The choice of final moisture content results in different styles of dried peaches, from soft and somewhat gooey to leathery to crunchy texture. Proper packaging, such as airtight containers or vacuum-sealed bags, helps to preserve the quality and prolong the shelf life of the dehydrated peach slices or halves (Figure 6 and Figure 7).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

The Freeze-drying Method and its Advantages and Disadvantages

Freeze-drying, also known as lyophilization, is a highly advantageous technique for dehydrating fruits and vegetables (Figure 8). It offers several benefits that make it an ideal technique for retaining the nutritional value, quality, and shelf life of peaches. One of the significant advantages of freeze-drying is the preservation of nutritional content. This method effectively removes water from the frozen fruit through a process called sublimation, while preserving vitamins, minerals, and antioxidants. Freeze-drying quickly eliminates all water by sublimating the ice within the frozen fruit under vacuum conditions. In other words, the water in the tissue is instantaneously converted from the solid (frozen) state to the gaseous (vapor) state when a critical reduced pressure level is reached. Freeze-drying is particularly suitable for crops containing heat-sensitive antioxidant compounds like tocopherols, ascorbic acid (Vitamin C), carotenoids, and phenolic compounds. Another advantage is the preservation of the fruit’s sensory attributes. Since freeze-drying rapidly and uniformly eliminates water content, it results in peaches that best keep their natural flavor, aroma, and color among all of the drying technologies (Figure 9). This means that freeze-dried peaches offer a pleasant consumption experience with the same enticing characteristics as fresh peaches.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Prolonged shelf life is another significant benefit of freeze-dried peach fruit compared to fresh peaches or traditionally dried peaches. By almost completely eliminating moisture, freeze-drying inhibits the growth of microorganisms that can cause spoilage. This permits significant flexibility in storage and distribution, securing the availability of peach fruit throughout the year.

However, it is important to consider some potential disadvantages of freeze-drying peach fruit. One challenge is the initial cost of the specialized equipment and facilities required for this process, which can be expensive for small-scale operations or individuals. Another disadvantage is the time-consuming features of freeze-drying. The process involves multiple stages: preparation, freezing, primary drying (sublimation), and secondary drying (desorption). Each stage needs thorough control of temperature and pressure, which can extend the overall processing time for freeze-dried peaches. Furthermore, freeze-drying may result in the loss of some volatile compounds (i.e., chemical gases) present in fresh peaches. Optimization of the process parameters is critical to minimize these losses and maintain the characteristic flavors in the freeze-dried product.

A summary of the advantages and disadvantages of the freeze-drying method is shown in Table 1.

Table 1. Advantages and disadvantages of the freeze-drying method.

Despite these challenges, freeze-drying remains an accepted and effective method for preserving peach fruit. It results in the availability of nutritious, flavorful, and long-lasting peach products that can be enjoyed throughout the year. Overall, freeze-drying technology is one potential method for significantly increasing peach consumption far beyond the harvest season. This approach assists in the preservation of the peach’s health benefits while enhancing its appeal to consumers.

The Mechanism of Freeze-drying Technology

The mechanism of freeze-drying technology involves several steps to efficiently remove water and preserve the fruit’s quality (Figure 10). The process starts by precisely selecting ripe and high-quality peaches that are washed to eliminate any impurities. After that, the peaches are sliced into the desired form and quickly frozen to a very low temperature, usually -40°F (-40°C). When the peaches are fully frozen, they are placed into a vacuum chamber in which the frozen water within the peaches undergoes sublimation, converting directly from ice to vapor without going through the liquid phase. This process removes most of the moisture from the peaches (typically less than 7% moisture content remains). The vacuum chamber creates an environment in which the frozen water in the fruit tissue can vaporize and be effectively removed from the peaches, leaving the peaches in a dried state. The moisture migrating from the fruit tissue condenses on the low-temperature refrigeration coils inside the vacuum chamber, maintaining a low humidity in the chamber that maximizes evaporation. The final step in the freeze-drying process is called desorption, in which the temperature of the vacuum chamber is gradually raised to aid in the removal of any remaining moisture. This ensures that the peach tissues are completely dried and have a low moisture content, which is critical for prolonged preservation. Throughout the freeze-drying process, it is essential to monitor and control various parameters such as temperature, pressure, and drying time. Proper control of these variables ensures optimal drying efficiency and maintains the quality of the freeze-dried peaches. As a result, freeze-dried peaches have a lightweight and porous texture; retain their original shape, flavor, and nutritional compounds; and keep an extended shelf life compared to fresh peaches (Figure 11).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Differences in Appearance between Freeze-dried and Dehydrated Peaches

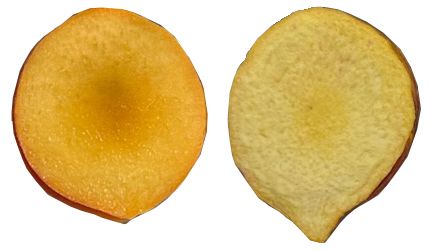

Freeze-dried and dehydrated peaches have some different characteristics (Figure 12). Freeze-dried peaches retain an extremely low moisture content, usually below 7%, and have a crisp and light texture similar to delicate chips, while dehydrated peaches possess a relatively higher moisture content ranging from 10% to 20% and have a chewier and denser consistency. Unlike the dehydration method, freeze-drying preserves the primary structure of peaches, resulting in minimal shrinkage and changes in shape (Figure 13). Moreover, freeze-dried peaches reveal a more pronounced and concentrated flavor and aroma, while dehydrated peaches retain flavor but may experience a loss of aroma. Freeze-dried peaches also have a longer shelf life than dehydrated peaches due to their lower moisture content, which inhibits microbial growth and preserves quality over an extended period.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

The color parameters indicate that freeze-dried peaches tend to retain a brighter and more vibrant color in comparison to dehydrated peaches. This is because freeze-drying better preserves the natural pigments present in the fruit, resulting in a visually appealing product with a vivid and intense hue. On the other hand, dehydrated peaches experienced some color changes during the drying process. The exposure to heat and the prolonged drying time causes slight browning or darkening of the fruit that results in a slightly less vibrant color compared to freeze-dried peaches (Figure 12).

Conclusion

The processes of dehydrating and freeze-drying peach fruit offer convenient and useful ways to preserve their natural flavor and nutritional value. The application of these modern drying techniques has resulted in the creation of a product with a significantly prolonged shelf life. The extended shelf life achieved through these techniques emphasizes their effectiveness in maintaining quality and freshness, thus providing consumers with a valuable and enduring option in the realm of preserved food products. The resulting dried peach products offer consumers a delicious and portable option while capturing the essence of the fruit for year-round enjoyment. Whether on its own or incorporated into different recipes, dried peach fruit stands as a flavorful and wholesome choice for those seeking a taste of nature’s goodness.

References

Brecht, J. K., M. A. Ritenour, A. Sarkhosh, M. Olmstead, J. X. Chaparro, J. A. Bartz, S. A. Sargent, and J. Van Sickle. 2023. “Harvesting and Postharvest Handling of Stone Fruit in Florida: HS1459, 4/2023.” EDIS 2023 (2). https://doi.org/10.32473/edis-HS1459-2023

Chandra, S., and D. Kumari. 2015. “Recent Development in Osmotic Dehydration of Fruit and Vegetables: A Review.” Critical Reviews in Food Science and Nutrition 55 (4): 552–561. https://doi.org/10.1080/10408398.2012.664830

Ciurzynska, A., and A. Lenart. 2011. “Freeze-drying—Application in Food Processing and Biotechnology—A Review.” Polish Journal of Food and Nutrition Sciences 61 (3): 165–171. https://doi.org/10.2478/v10222-011-0017-5

Layne, D., and D. Bassi, eds. 2008. The Peach: Botany, Production and Uses. CAB International. https://doi.org/10.1079/9781845933869.0000

Lill, R. E., E. M. O'Donoghue, and G. A. King. 1989. “Postharvest Physiology of Peaches and Nectarines.” In Vol. 11, Horticultural Reviews, edited by J. Janick, 413–452. https://doi.org/10.1002/9781118060841

Ma, Y., J. Yi, X. Jin, X. Li, S. Feng, and J. Bi. 2022. “Freeze-drying of Fruits and Vegetables in Food Industry: Effects on Phytochemicals and Bioactive Properties Attributes—A Comprehensive Review.” Food Reviews International 39 (9): 6611–6629. https://doi.org/10.1080/87559129.2022.2122992

Marques, L. G., A. M. Silveira, and J. T. Freire. 2006. “Freeze-drying Characteristics of Tropical Fruits.” Drying Technology 24 (4): 457–463. https://doi.org/10.1080/07373930600611919

Megías-Pérez, R., J. Gamboa-Santos, A. C. Soria, M. Villamiel, and A. Montilla. 2014. “Survey of Quality Indicators in Commercial Dehydrated Fruits.” Food Chemistry 150: 41–48. https://doi.org/10.1016/j.foodchem.2013.10.141

Sagar, V. R., and P. Suresh Kumar. 2010. “Recent Advances in Drying and Dehydration of Fruits and Vegetables: A Review.” Journal of Food Science and Technology 47: 15–26. https://doi.org/10.1007/s13197-010-0010-8

Serna-Cock, L., D. P. Vargas-Muñoz, and A. A. Aponte. 2015. “Structural, Physical, Functional and Nutraceutical Changes of Freeze-dried Fruit.” African Journal of Biotechnology 14 (6): 442–450. https://doi.org/10.5897/AJB2014.14189