Introduction

Blackberry (Rubus spp.) belongs to the Rubus genus of the Rosaceae family and is a deciduous fruit crop (Figure 1). Blackberries are usually small, round, and dark purple to black. Blackberry fruit is comprised of multiple drupelets that cluster together to form a berry. The berries have a glossy appearance when they mature and are ready to harvest. Blackberries have a complex flavor profile that blends sweetness and acidity, and taste may vary depending on the variety and maturity stage. They are rich in nutrients, vitamins, minerals, and antioxidants. The anthocyanins in blackberries have antioxidant properties and contribute to their dark color and potential health benefits. Blackberries are best grown in temperate climates due to the requirement of a certain number of chilling hours to break dormancy.

Blackberry is a new emerging fruit crop in Florida due to increased interest by strawberry and blueberry growers. Blackberries are harvested in May-June in Florida. There are several varieties of blackberries, including thorned and thornless varieties, some of which are native to Florida. The thornless varieties are popular among gardeners, commercial producers, and consumers due to their ease of handling. The fresh blackberry fruit crop is emerging in North Florida with high market demand and less input cost with efficient economic returns. It is highly profitable with a wholesale price at $0.84/lb (NASS 2017), so it could be a good addition for sustainable and profitable specialty crop production in Florida. This publication aims to provide a general overview of the importance of the trellis system, different types of trellises, and their installation in blackberry production for county and state Extension faculty, growers, homeowners, and students interested in growing blackberries in Florida.

Credit: Ali Sarkhosh, UF/IFAS

Trellis System in Blackberry

A trellis system is a common and important component in commercial blackberry production. It establishes a structured support system that manages the growth of blackberry plants to improve fruit quality, facilitate harvesting, and enhance overall plant health. Trellising also helps to maximize sunlight exposure and airflow, which is crucial for healthy plant growth and disease prevention.

Types of Trellis Systems

Several trellis systems are used in blackberry production, and the choice of system can depend on factors such as climate, variety, and available space. Some standard trellis designs include the following:

V-shaped Trellis System

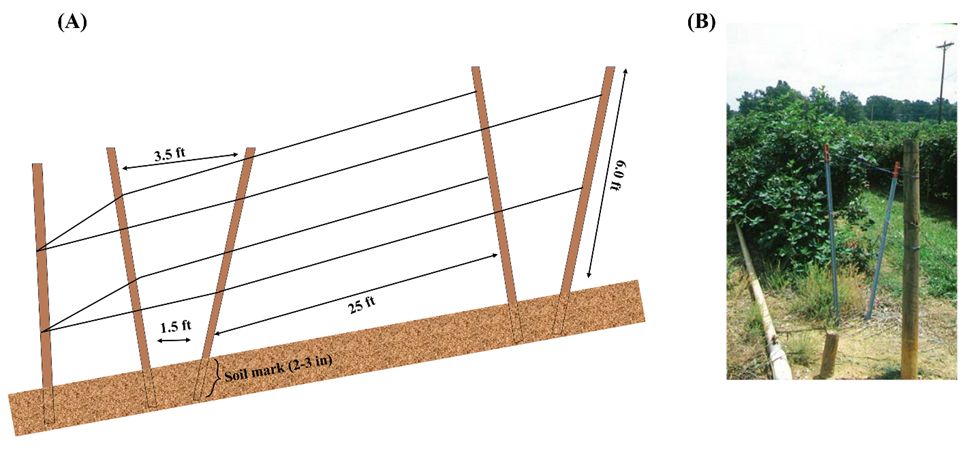

The V-shaped trellis system is a trellis design commonly used in blackberry cultivation (Figure 2). The V-shaped arrangement of wires allows for optimal sunlight exposure, enhances airflow, reduces humidity, and minimizes the risk of diseases, making it easier to harvest fruits. Sturdy posts are installed regularly along the rows of blackberry plants to support the trellis. Two parallel wires or strings run between the V-shaped wooden or steel posts. The lower wire is usually set at a height of 2 to 3 ft above the ground, while the upper wire is set higher, typically 4 to 5 ft above the ground. The blackberry canes (branches/stems) are trained to these wires. As the blackberry canes grow, they are gently tied to the lower wire of the V-shaped trellis. This encourages the canes to grow upward along the trellis system. As the canes grow, they naturally produce lateral branches that produce the fruits. These new branches are also gently tied to the trellis wires to maintain an organized and open canopy.

Credit: (A) Shahid Iqbal UF/IFAS; and (B) Gina Fernandez, NC State University

T-Trellis System

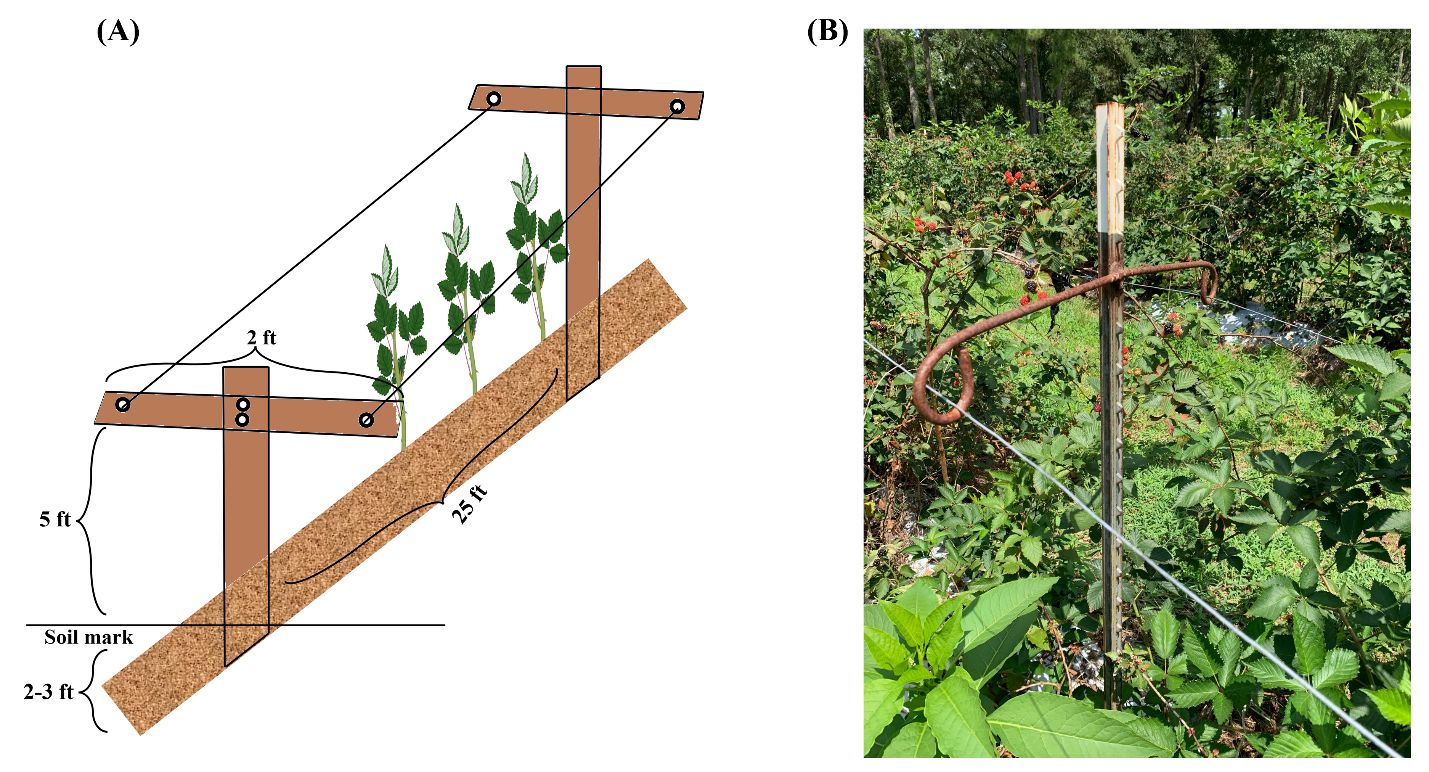

The T-trellis system is widely used for training and supporting blackberry plants. It includes creating a frame like the letter "T" using posts, wires, and cross-arms (Figure 3). This system is particularly effective for erect and semi-erect blackberry varieties. This trellis is installed by mounting sturdy posts along the row of blackberry plants. These posts should be tall enough to accommodate the height of mature blackberry canes. The posts are typically installed at the end of each row and intermittently between them. The wires are horizontally attached between the posts. In this trellis system, wires are spaced vertically at different heights, usually 3 to 4 ft apart. The lower wires support the new growing canes, while the higher wires help to manage the fruiting canes' growth and positioning. Cross-arms are connected to the top of each post, forming a "T" shape that provides additional horizontal support for the fruiting canes and helps distribute their weight evenly.

Credit: (A) Shahid Iqbal and (B) Muhammad A. Shahid, UF/IFAS

I-Trellis System

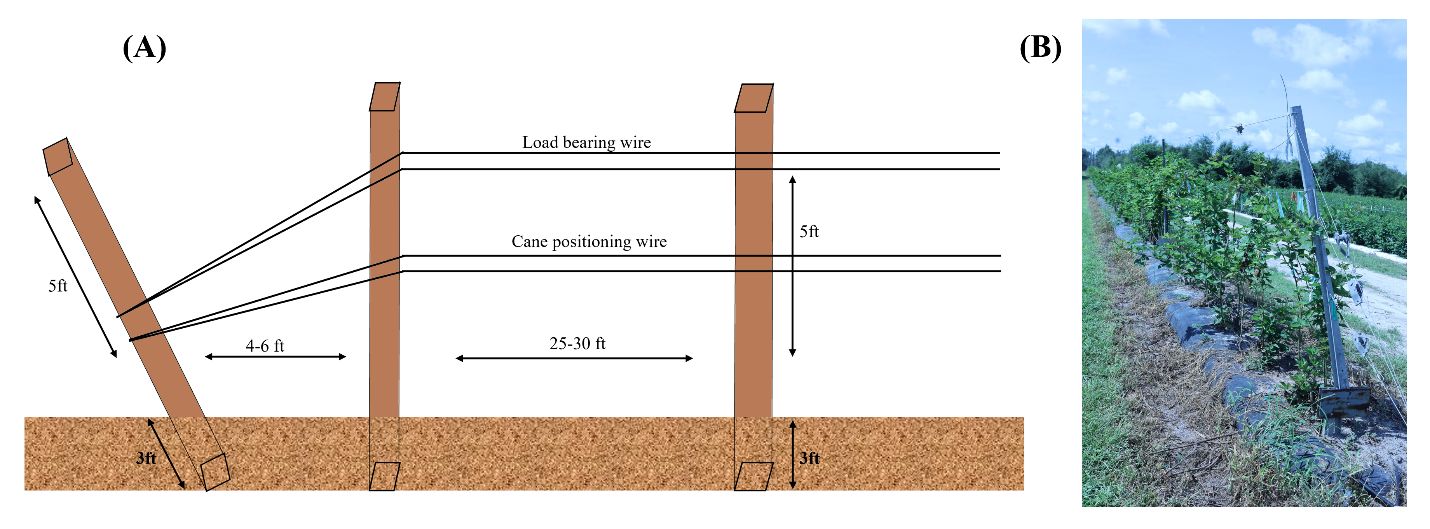

The "I-trellis," or "vertical trellis," is a support system used in blackberry to train canes vertically along single or multiple wires. The I-trellis system is particularly suitable for erect or semi-erect blackberry varieties, which naturally grow in a more upright pattern (Figure 4).

Credit: (A) Shahid Iqbal and (B) Muhammad A. Shahid, UF/IFAS

The I-trellis is constructed using sturdy posts which are positioned along the row of blackberry plants at regular intervals. The posts can be made of wood or metal, securely anchored to the ground. A single wire or multiple wires are horizontally connected between the posts at different heights. The number of wires can vary depending on plant density and desired canopy height. As the blackberry canes grow, the strongest and healthiest canes are trained vertically and gently tied to the wires, ensuring they have sufficient support to grow upright. I-trellis encourages the vertical growth of blackberry canes, optimizing sunlight exposure to all plant parts. By training canes vertically, the risk of canes touching the ground and possibly being inoculated or damaged is minimized. It is important to note that while the I-trellis system has its benefits, it may require more frequent and diligent pruning to manage vertical growth and keep the canes from becoming overcrowded. Like any trellis system, proper care and maintenance, including regular pruning and training, are essential to ensure a successful and good quality harvest of blackberries.

Parallel Trellis System

The parallel trellis system is a specific arrangement used in blackberry production. It involves setting up parallel rows of wires or posts to support and guide the growth of blackberry canes (Figure 5). This system is particularly suitable for trailing blackberry varieties with long and flexible canes that often bend and stretch during their growth process.

Credit: Muhammad A. Shahid, UF/IFAS

To assemble this trellis system, sturdy posts are installed along the rows of blackberry plants at regular intervals. These posts should be strong enough to support the weight of the growing canes. Multiple individual wires are connected between the posts, parallel to each other and at different heights. The number of wire rows may vary, but usually, there are at least two. As the blackberry canes grow, they should be guided along the wires in a horizontal or slightly arched pattern. The parallel trellis system supports the trailing canes, preventing them from bending, breaking, or touching the ground. The horizontal arrangement of the canes provides optimal sunlight to all plant parts, promoting healthy growth and fruit production. The specific details of implementing the parallel trellis system may vary based on the growing blackberry variety, local growing conditions, and the grower's preferences.

Rotating Cross-Arm Trellis

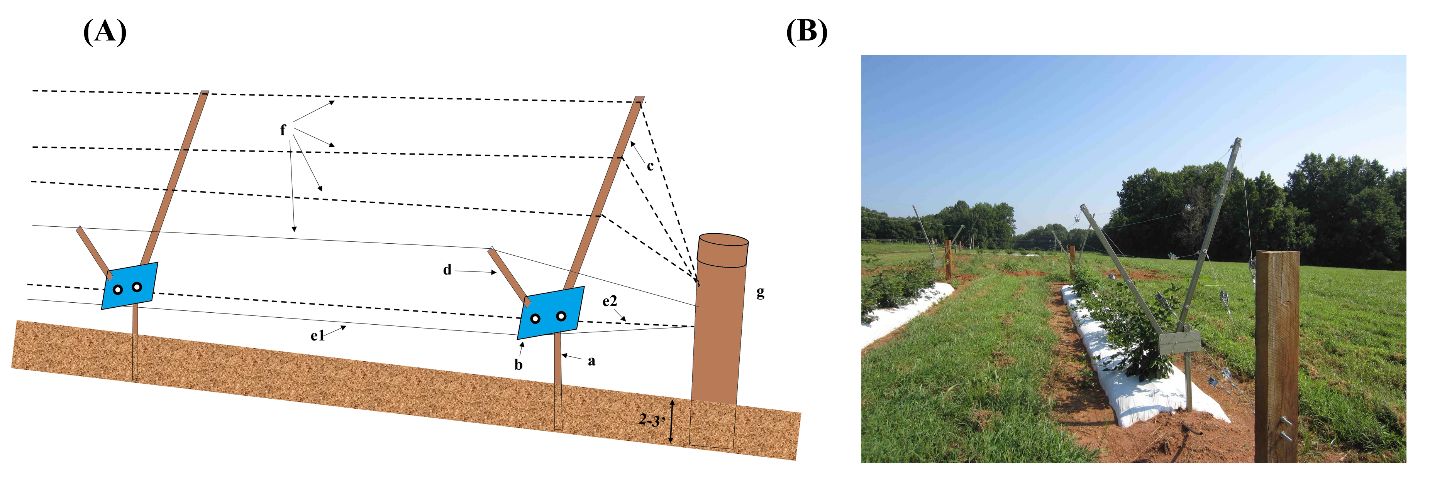

The rotating cross-arm (RCA) trellis is a specialized type of trellis system used in blackberry to manage the growth of the canes and optimize fruit production (Figure 6). This system is particularly effective for training semi-erect or trailing blackberry varieties. The rotating cross-arm trellis allows for easy adjustment of the plant's growth angle, ensuring the canes are exposed to adequate sunlight and airflow. The main advantage of this system is to allow fruit set only on one side of the trellis, which enables easy and more efficient harvesting.

Credit: (A) Shahid Iqbal, UF/IFAS; and (B) Gina Fernandez, NC State University

This system is established by installing sturdy posts along the blackberry plant row. The posts need to be strong enough to support the weight of the trellis structure and the growing canes. The unique feature of this system is the rotating cross-arms. These arms are horizontal structures extending from the top of the posts, forming a cross shape. The cross-arms can rotate around the posts, allowing growers to adjust the canes' angle as they grow. Horizontal wires or strings are stretched along the cross-arms, supporting the growing canes and fruit. It should be noted that although the rotating cross-arm trellis offers several advantages, it might also involve more complexity in design and setup compared to traditional trellis systems. Growers interested in implementing this type of trellis should consider seeking advice from local horticultural experts, agricultural Extension offices, or experienced blackberry growers who can provide insights specific to the region and conditions.

Summary

The trellis system is crucial for optimizing blackberry production by providing structural support, promoting healthy growth, and facilitating effective management practices. Common trellis systems used for blackberry production train plants to grow in a specific pattern. These trellis systems allow the plants to maximize sunlight exposure, enhance air circulation, and facilitate efficient space utilization. Selecting the optimum trellis for Florida growers involves considering several factors, such as blackberry variety and growth habit, available space, climate, cost, adoptability, and grower's preferences. When properly managed, a well-designed trellis system contributes to the success of blackberry cultivation with high-quality produce.

Reference

USDA-NASS. 2018. Noncitrus Fruits and Nuts: 2017 Summary. https://www.nass.usda.gov/Publications/Todays_Reports/reports/ncit0618.pdf

Further Reading

Andersen, P. C. 2020. “The Blackberry.” HS807. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/HS104

Poling, E. B. 1997. “Blackberries.” Journal of Small Fruit & Viticulture 4 (1–2): 33–69. https://doi.org/10.1300/J065v04n01_02

Strik, B. C., and C. E. Finn. 2012. “Blackberry Production Systems- A Worldwide Perspective.” Acta Horticulturae 946: 341–347. https://doi.org/10.17660/ActaHortic.2012.946.56

Takeda, F., D. M. Glenn, and T. Tworkoski. 2013. “Rotating Cross-arm Trellis Technology for Blackberry Production.” Journal of Berry Research 3 (1): 25–40. https://doi.org/10.3233/JBR-130044

Stiles, H. D. 1995. “Blackberry Trellises.” HortScience 30 (3): 430f–431. https://doi.org/10.21273/HORTSCI.30.3.430f