Introduction

Persimmon fruits are classified as astringent or non-astringent, depending on the level of astringency that the unripe or partially ripe fruits exhibit at the time of harvest (Figure 1). While consumers typically prefer non-astringent varieties, the cultivation of astringent varieties notably remains common. Both types are commercially harvested at the mature-firm stage, and non-astringent cultivars can be eaten from firm through soft stages (Figure 2). However, astringent persimmons cannot be eaten at the firm stage because of their high tannin content. Astringency is a sensation caused by tannins present in the unripe flesh that can make the mouth feel dry, cause puckering, numb the tongue, and constrict the throat. Sometimes, it may also impart a bitter taste. Astringency decreases as the fruit ripens until it is no longer present in fully ripe fruit. If astringent types are to be eaten prior to achieving the full-ripe stage, astringency must be mitigated to enhance the palatability and consumer acceptability. Removing astringency from persimmon fruit can be achieved through postharvest approaches that involve polymerizing (i.e., when several molecules chemically combine into larger molecules) soluble tannins, making them insoluble and non-astringent. The purpose of this publication is to introduce consumers, growers, Extension agents, and specialists to postharvest methods for reducing astringency in unripe persimmons, making them more palatable and acceptable for consumption.

Tannin Biosynthesis

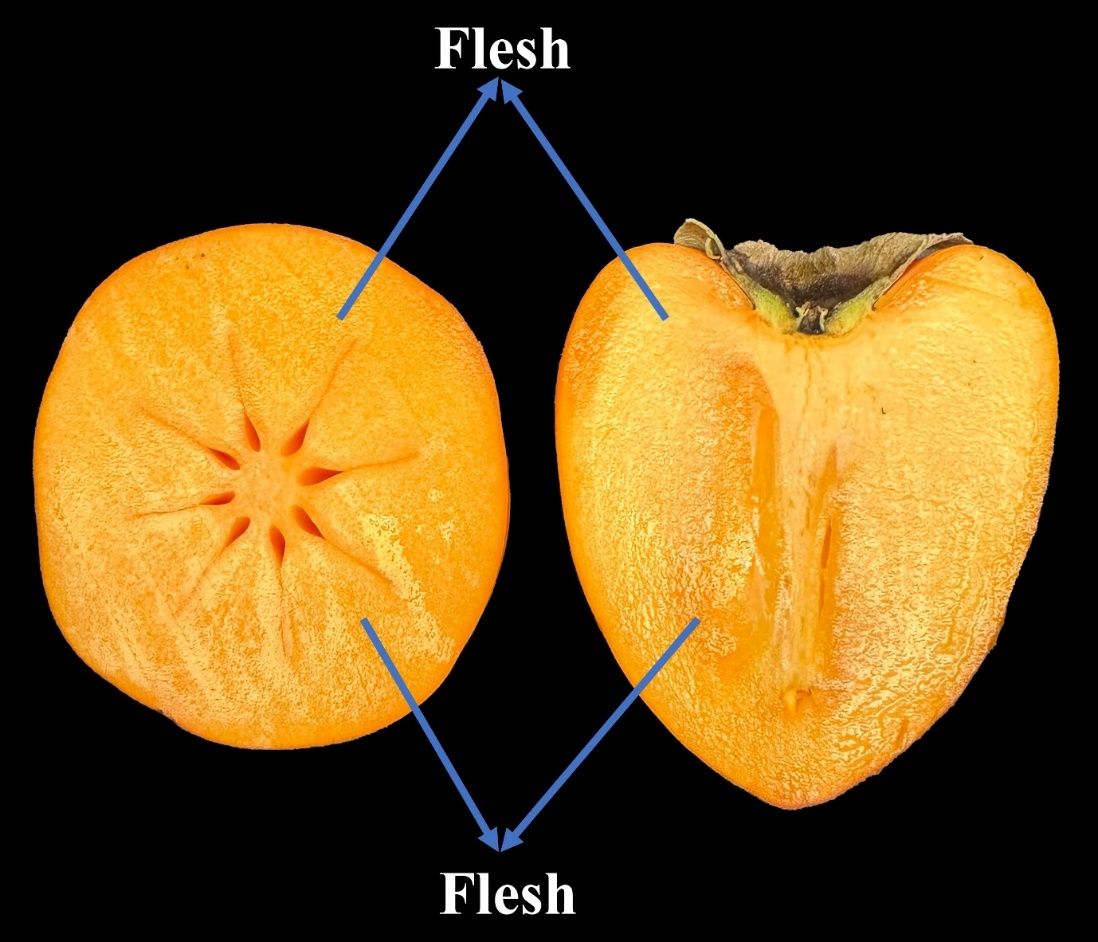

In persimmons, tannins can be classified into three categories including complex, condensed, and hydrolyzable. Astringency in persimmons results from the accumulation of tannins in the vacuoles of cells in the fruit’s flesh (mesocarp); these concentrated tannins are also called “condensed tannins” or “proanthocyanidins” (Figure 3). The binding of those tannins with saliva proteins in the mouth causes the astringency sensation when consuming persimmons.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Biosynthesis is when substrates bind with enzymes in reactions that produce complex compounds from simpler compounds. A metabolic pathway is a connection among several biosynthetic reactions in one cell. Persimmon proanthocyanidins are primarily composed of catechins or epicatechins. These two flavonoids are biosynthesized from substrates of the shikimic acid pathway, following the biosynthetic pathways of phenylpropanoids and flavonoids, which originate from gallic acid units or precursors of the anthocyanin pathway. Leucoanthocyanidin reductase and anthocyanidin reductase are two key enzymes identified in the proanthocyanidins pathway. Persimmons accumulate proanthocyanidins during fruit development. In non-astringent varieties, the astringency is lost during fruit development, while in astringent varieties, the fruit remains astringent even at commercial (firm) maturity. In the case of proanthocyanidin in non-astringent varieties, the early-stage expression of genes responsible for encoding enzymes in the biosynthetic pathway can be decreased. This reduction disrupts the proanthocyanidin accumulation process. In addition, acetaldehyde is the compound responsible for the polymerization of proanthocyanidins and the consequent reduction of astringency. In non-astringent varieties, proanthocyanidins are polymerized by acetaldehyde in the final stages of fruit development and then transported to the vacuole, blocking the biosynthetic pathway.

Methods to Reduce Astringency

The reduction of astringency in persimmons through postharvest approaches can make these fruit palatable and more enjoyable to eat. The following techniques involve transforming the fruit soluble tannins into polymerized and insoluble tannins, ultimately resulting in a sweeter and smoother eating experience. The process of removing astringency in persimmons is often referred to as “deastringency.” Understanding these methods is crucial for both consumers and producers, as it directly impacts the marketability and consumption of astringent persimmons.

Ripening at Room Temperature

Storing astringent persimmons at room temperature reduces astringency and improves overall flavor due to fruit ripening (Figure 4). Allowing persimmons to ripen naturally at room temperature is the most environmentally friendly and simplest astringency reduction method. Ripening requires less effort, consumes less energy than other astringency reduction methods, and preserves the natural texture and flavor of the fruit. The mechanism behind this process is primarily attributed to the fruit’s unique tannin content. As the persimmons ripen, these tannins undergo a chemical transformation. When exposed to air and stored at room temperature, the tannins slowly polymerize and become insoluble. This process leads to the precipitation (i.e., separation) of tannins, effectively reducing their astringency and making the fruit more palatable. The room temperature storage allows for a controlled and gradual ripening, ensuring that the persimmons become sweeter and less astringent over time, resulting in a delightful and enjoyable fruit to eat. The only disadvantage of this method is that it takes time for the tannins to polymerize and for the astringency to decrease. As a result, a long ripening process is required, which may increase the risk of decay (Figure 5). However, for those who prefer the natural taste and texture of persimmons, this is the most attractive option.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Freezing Treatment

Freezing is another potential method for removing the astringency of persimmons (Figures 6, 7). Freezing the persimmons to approximately -4°F (-20°C) polymerizes soluble tannins into insoluble tannins, which are less reactive and bitter. The frozen persimmons can be eaten as a frozen treat or thawed and enjoyed as a soft and sweet fruit. The flavor and texture of the thawed persimmons may not be identical to fresh, ripe persimmons, but the freezing method is a great way to salvage astringent persimmons and enjoy them when they are not yet fully ripe. However, very rapid freezing, such as using liquid nitrogen, is not an effective method for eliminating astringency in persimmons.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Heat Treatments

Heat treatments can play a significant role in reducing astringency in persimmons. Heat treatments can help break down tannins and make the fruit more palatable. The most common heat-based deastringency method is hot water treatment. This method involves immersing the persimmons in hot water with temperatures between 86°F (30°C) and 104°F (40°C) for one to five hours (higher temperatures require shorter durations). This treatment leads to breakdown of the tannins and softening of the fruit by triggering polyphenol oxidase and peroxidase enzymes, which help degrade tannins and other astringent compounds. Another method involves subjecting the persimmons to steam, which also softens the fruit and precipitates the tannins. It is important to note that the effectiveness of heat treatments depends on the duration and temperature at which they are applied. Different varieties of persimmons may also require slightly different conditions. Therefore, various time-temperature combinations should be tested to find the optimal conditions for reducing astringency while maintaining fruit quality.

Ethylene Treatment

Ethylene is a natural plant hormone that accelerates the ripening process in fruits. Exposing persimmons to exogenous ethylene, either as a gas or using ethephon, accelerates the ripening process by triggering the synthesis of endogenous ethylene within the fruit, making more uniform ripening within a given lot of fruit. Ethephon is a chemical compound sold as a powder that releases ethylene gas upon being dissolved in water. Immersing persimmons in a 1,000-ppm aqueous solution of ethephon for one hour and then storing the fruit at room temperature for four days removes astringency. Ethephon is an EPA-registered plant growth regulator, and as such, it must be used strictly in accordance with the label instructions.

Note that the effectiveness of ethylene treatments may vary depending on the variety of persimmon, its initial maturity stage, and the level of astringency. Moreover, the timing and concentration of ethylene exposure should be carefully monitored to avoid over-ripening, which can lead to a loss of fruit quality and promote decay. Alternatively, consumers can place the persimmon fruit in a bag (paper or plastic) with an ethylene-producing fruit such as a ripe banana, apple, or tomato to speed up the ripening process at home.

Carbon Dioxide (CO2) Treatment

Using CO2 to remove the astringency of persimmons is a commonly used technique in the postharvest processing of this fruit. Its application demands the use of sealed chambers with strict control of temperature and CO2 levels inside them. The CO2 treatment involves storing the persimmon fruit in a high CO2 atmosphere (above 80%) for a short period of time (6 to 24 hours) at a specific temperature (68°F to 104°F; 20°C to 40°C), followed by subsequent storage in normal air for a few days. This treatment triggers anaerobic respiration in the fruit, which leads to the formation and accumulation of acetaldehyde, a volatile compound that reacts with tannins and causes them to polymerize and precipitate. In addition, CO2 inhibits the activity of enzymes responsible for tannin synthesis in persimmons.

Exposure to elevated CO2 levels can also affect the physiology of the persimmon fruit, such as the breakdown of cell walls and alterations in fruit texture. While CO2 is effective at removing astringency, it should be used carefully to avoid overexposure, which can negatively impact the fruit’s flavor, texture, and overall quality. High CO2 concentrations induce oxidative stress, damage cell membrane structures, and lead to intracellular membrane decompartmentalization. This, in turn, accelerates flesh browning due to reactions involving phenolic substrates and polyphenol oxidase. These negative results can lead to significant economic losses. Despite these challenges, CO2 treatment is widely used in the persimmon industry to ensure that consumers can enjoy a non-astringent, palatable fruit before it is fully ripe.

Modified Atmosphere Packaging (MAP)

Another method that utilizes high CO2 to remove the astringency of persimmons is MAP. By using specially designed packages, it is possible to create an atmosphere that equilibrates at higher concentrations of CO2 and lower levels of O2. Like the high CO2 treatments, this condition promotes the formation and accumulation of acetaldehyde by restricting the amount of O2 available for respiration; CO2 accumulates as anaerobic respiration is induced (i.e., fermentation). However, it should be noted that this treatment may lead to significant fruit softening, which is a key parameter considered by consumers when selecting fruit. Also, anaerobic conditions may also cause off-flavors/aromas in fruit.

Vacuum storage in plastic films is another way to modify the atmosphere. The removal of air from the package creates a low O2 atmosphere that induces anaerobic respiration, generating elevated CO2 levels. Persimmons stored at 68°F (20°C) and packaged in polyethylene films show faster astringency reduction when CO2 is present inside the package.

Traditional and Modern Drying Techniques

Drying methods can transform astringent persimmons into sweet, non-astringent, dried fruit that is popular for consumption. The drying process alters the fruit’s texture and composition and rapidly reduces astringency. Traditional sun drying methods are often used to produce dried persimmons. During sun drying, persimmon slices are exposed to direct sunlight and air, allowing them to gradually lose moisture. This accelerates the ripening process, converting the astringent soluble tannins into non-astringent forms.

Dehydration and freeze-drying are two modern methods that more quickly reduce astringency in persimmon fruit slices by rapidly removing water. Commercial dehydrators control temperature and relative humidity conditions in a high-velocity air environment. Examples of dehydrated fruit slices are shown in Figure 8. Freeze-drying is a process that removes the water from frozen fruit by sublimation (i.e., converting water directly from ice to vapor) under low pressure. Although freeze-drying better maintains the shape, texture, and quality of the fruit compared with drying or dehydration (Figure 9), dehydrated (air-dried) persimmons are less astringent than the freeze-dried persimmons. Therefore, dehydration may be a more preferable method for mitigating the astringency of persimmons.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Ethanol Treatment

Ethanol treatment is a method of reducing astringency in persimmon by spraying the fruit with a 30% to 40% ethanol solution or by packing the fruit in a sealed container with ethanol or sake vapors for 10 to 14 days at 50°F to 59°F (10°C to 15°C) (Figure 10). Ethanol is a good solvent for tannins, and exposure to ethanol causes the tannins in the fruit flesh to dissolve in the alcohol, diluting their concentration and accelerating the natural process of tannin polymerization. However, ethanol treatment may also increase the alcohol content of the fruit, which may not be desirable for some consumers.

The effectiveness of ethanol treatment depends on the concentration, duration, and temperature of the treatment, as well as the persimmon variety and ripeness stage. Note that while ethanol treatment is effective at reducing astringency in persimmons, regulatory and safety precautions should be considered when using ethanol for fruit deastringency.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

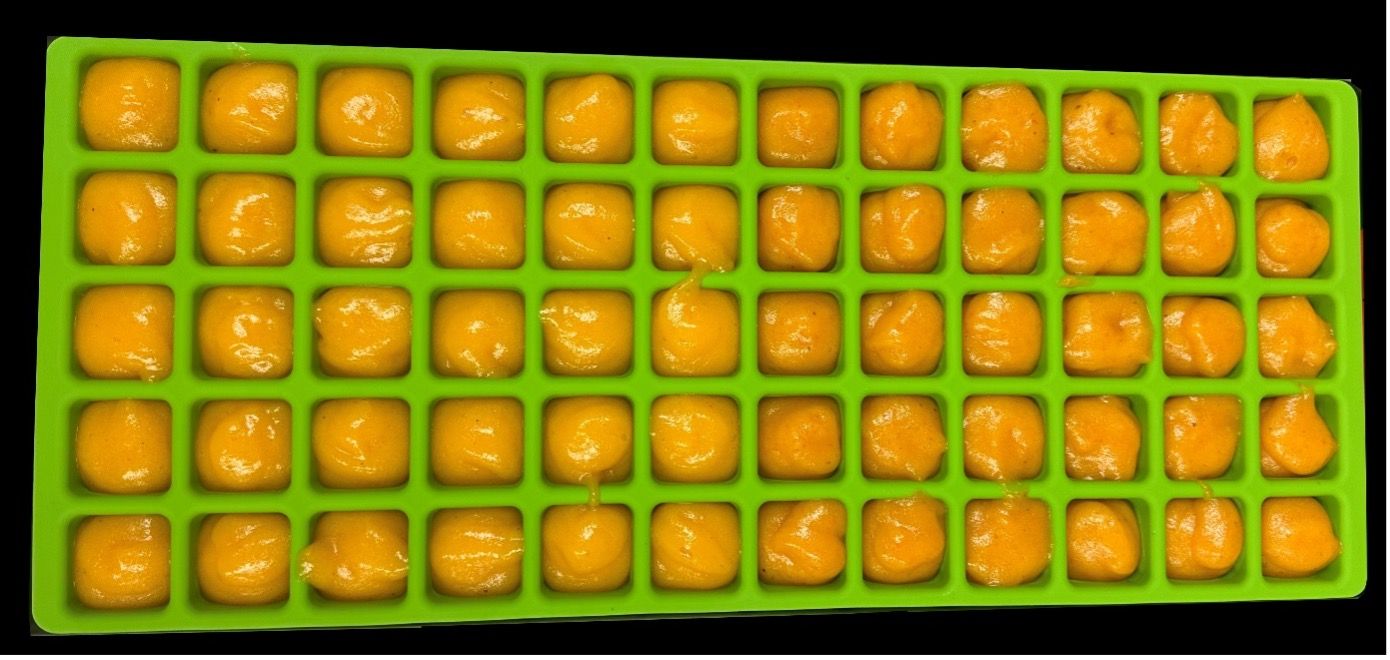

Polysaccharide Treatment

Polysaccharide treatment is a method by which polysaccharides are mixed with persimmon in paste form to reduce astringency while maintaining sensory qualities. Polysaccharides that exhibit the highest astringency removal efficiencies include pectin, carrageenan, xanthan gum, and sodium alginate. The necessary amount and compatible type of polysaccharide may vary depending on the desired properties of the persimmon paste. Polysaccharide treatment can also be combined with heating or freezing to further reduce astringency and enhance the quality of the persimmon paste (Figure 11).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Dry Ice Treatment

This method involves storing the persimmons with dry ice, which combines generation of CO2 with cold temperatures. This method can reduce astringency and soluble tannin content, but it may also affect the color and quality of the fruit.

Other Methods

Lesser used methods include immersing the persimmons in water, acetic acid (vinegar), or calcium chloride, all of which can remove or reduce the astringency by leaching out some of the tannins or by changing their chemical structure. The immersion time may vary depending on the type and ripeness of the persimmons. Persimmons can also be placed in hermetically sealed chambers at temperatures between 68°F and 82.4°F (20°C and 28°C) and 80% relative humidity, then exposed to acetylene gas from the combustion of calcium carbonate or to the gas from burning sawdust. Sprinkling a tannin-removing powder, such as Kaki no Tane or Shakushi, can help remove the astringency in persimmons. In addition, placing the persimmons in a microwave for 30 to 60 seconds can help to break down the tannins and soften the fruit. The application of lemon juice onto the persimmons serves to neutralize the tannins.

Further Reading

Amorim, C., L. R. Antoniolli, B. Orsi, and R. A. Kluge. 2023. “Advances in Metabolism and Genetic Control of Astringency in Persimmon (Diospyros kaki Thunb.) Fruit: A Review.” Scientia Horticulturae 308: 111561. https://doi.org/10.1016/j.scienta.2022.111561

Das, P. R., and J. B. Eun. 2021. “Removal of Astringency in Persimmon Fruits (Diospyros kaki) Subjected to Different Freezing Temperature Treatments.” Journal of Food Science and Technology 58: 3154–3163. https://doi.org/10.1007/s13197-020-04818-3

Fathi-Najafabadi, A., C. Besada, R. Gil, D. Tormo, P. Navarro, and A. Salvador. 2022. “Application of a New Wax Containing Ethanol as a Method to Remove Persimmon Astringency during Cold Storage.” Journal of Food Science and Technology 58: 268–278. https://doi.org/10.1007/s13197-021-05011-w

González, C. M., R. Gil, G. Moraga, and A. Salvador. 2021. “Natural Drying of Astringent and Non-astringent Persimmon ‘Rojo Brillante’. Drying Kinetics and Physico-chemical Properties.” Foods 10 (3): 647. https://doi.org/10.3390/foods10030647

González, C. M., I. Hernando, and G. Moraga. 2021. “Influence of Ripening Stage and De‐astringency Treatment on the Production of Dehydrated Persimmon Snacks.” Journal of the Science of Food and Agriculture 101 (2): 603–612. https://doi.org/10.1002/jsfa.10672

Han, W., K. Cao, S. Diao, P. Sun, H. Li, Y. Mai, Y. Suo, and J. Fu. 2022. “Characterization of Browning during CO2 Deastringency Treatment in Astringent Persimmon Fruit.” Journal of Food Measurement and Characterization 16 (3): 2273–2281. https://doi.org/10.1007/s11694-022-01298-1

Matheus, J. R. V., C. J. D. Andrade, R. F. Miyahira, and A. E. C. Fai. 2022. “Persimmon (Diospyros kaki L.): Chemical Properties, Bioactive Compounds and Potential Use in the Development of New Products–A Review.” Food Reviews International 38 (4): 384–401. https://doi.org/10.1080/87559129.2020.1733597

Ozdemir, A. E., E. Candir, C. Toplu, and E. Yildiz. 2020. “Effect of Hot Water Treatment on Astringency Removal in Persimmon Cultivars.” International Journal of Fruit Science 20 (sup2): S557–S569. https://doi.org/10.1080/15538362.2020.1746729

Park, D., S. Tilahun, and C. S. Jeong. 2022. “Ripening Mechanism of Astringent Persimmon by Ethylene under Cold Storage.” The Journal of Horticultural Science and Biotechnology 97 (3): 376–384. https://doi.org/10.1080/14620316.2021.2008816

Sarkhosh, A., P. C. Andersen, and D. M. Huff. 2020. “Japanese Persimmon Cultivars in Florida: SP101/MG242, rev. 2/2020.” EDIS 2020 (1). https://doi.org/10.32473/edis-mg242-2020

Sarkhosh, A., F. Habibi, M. A. Shahid, S. A. Sargent, and J. K. Brecht. 2024. “Dried Persimmon Fruit: A Year-round Available Product: HS1479, 4/2024.” EDIS 2024 (2). https://doi.org/10.32473/edis-hs1479-2024

Sugiura, M., T. Suzuki, T. Niikawa, H. Ogino, and T. Imaizumi. 2022. “Quick Removal of Persimmon Astringency by Medium High Hydrostatic Pressure Treatment.” Acta Horticulturae 1338: 351–356. https://doi.org/10.17660/ActaHortic.2022.1338.50

Tessmer, M. A., R. A. Kluge, and B. Appezzato-da-Glória. 2014. “The Accumulation of Tannins during the Development of ‘Giombo’ and ‘Fuyu’ Persimmon Fruits.” Scientia Horticulturae 172: 292–299. https://doi.org/10.1016/j.scienta.2014.04.023

Tsurunaga, Y., T. Takahashi, M. Kanou, M. Onda, and M. Ishigaki. 2022. “Removal of Astringency from Persimmon Paste via Polysaccharide Treatment.” Heliyon 8 (9): e10716. https://doi.org/10.1016/j.heliyon.2022.e10716

Wu, W., Q. G. Zhu, W. Q. Wang, D. Grierson, and X. R. Yin. 2022. “Molecular Basis of the Formation and Removal of Fruit Astringency.” Food Chemistry 372: 131234. https://doi.org/10.1016/j.foodchem.2021.131234

Zhu, Q. G., W. Wu, and X. R. Yin. 2022. “Transcriptomics during Artificial Deastringency Treatment.” In The Persimmon Genome. Compendium of Plant Genomes, edited by R. Tao and Z. Luo. Cham, Switzerland: Springer International. https://doi.org/10.1007/978-3-031-05584-3_13