Introduction

The drift of spray from pesticide applications can expose people, plants and animals, and the environment to pesticide residues that can cause health and environmental effects and property damage. Agricultural practices are poorly understood by the public, which causes anxiety and sometimes overreaction to a situation. Even the application of fertilizers or biological pesticides, like Bt or pheromones, can be perceived as a danger to the general public. Drift can lead to litigation, financially damaging court costs, and appeals to restrict or ban the use of crop protection materials. Urbanization has led to much of Florida's agricultural production being in areas of close proximity to the general public, including residential subdivisions, assisted living facilities, hospitals, and schools. Such sensitive sites heighten the need for drift mitigation measures to be taken by applicators of pesticides, particularly in areas where children and the elderly are present.

Drift can be defined simply as the unintentional airborne movement of pesticides to nontarget areas. The goal of all pesticide applications is to reach a specific target and remain there. Scientists recognize that almost every pesticide application produces some amount of drift away from the target area. Not all drift may be harmful or illegal. Because some drift can occur with any application, the laws focus on preventing substantial drift. How much a pesticide may drift and whether it is harmful depends on interrelated factors that can be complex.

Drift is a significant legal concern in Florida. During 2009–2010, the Florida Department of Agriculture and Consumer Services (FDACS), which is the state pesticide regulatory agency, initiated 39 investigations in response to allegations of drift. Where significant drift does occur, it can damage or contaminate sensitive crops, poison bees, pose health risks to humans and animals, and contaminate soil and water in adjacent areas (Figure 1). Applicators are legally responsible for the damages resulting from the off-target movement of pesticides. It is impossible to eliminate drift totally, but it is possible to reduce it to a legal level. The purpose of this guide is to discuss factors influencing drift and provide common-sense solutions for minimizing potential drift problems.

Credit: UF/IFAS Pesticide Information Office

Drift in General

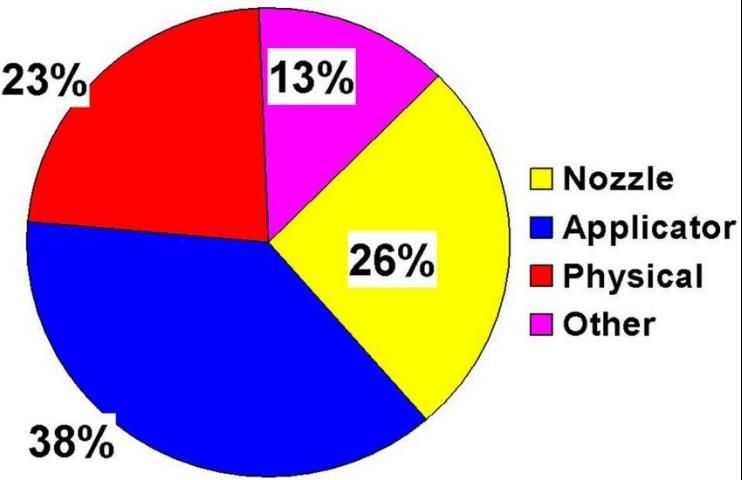

Why does drift occur? Surveys during the 1990s by insurance companies investigating damage claims determined that the most common reason was applicator error (Figure 2).

Credit: UF/IFAS Pesticide Information Office

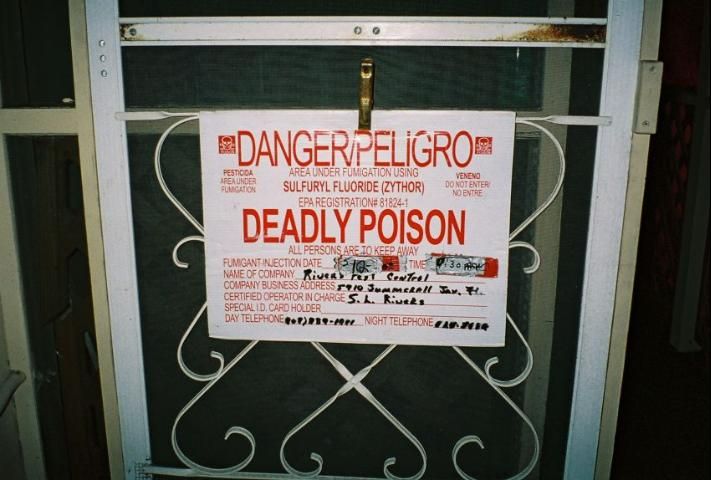

When does drift occur? Drift is not limited to the period during or immediately after an application because it can occur hours or even days later. But drift typically occurs during or shortly after the pesticide is applied and occurs when wind or application equipment blows the pesticide off the intended site. Post-application drift occurs after an application is completed. Post-application drift may be the result of an illegal application; for example, an applicator may neglect to follow fumigant application rules. Fumigant pesticides can escape quickly from application sites and cause problems, resulting in illegal drift. On the other hand, post-application drift may also occur with correct applications. Days after application, pesticides can volatilize into a gas. Low levels of pesticides may be carried long distances by air currents. Vapor drift from a legal pesticide application is sometimes difficult to predict. It depends on such factors as what the weather will be even days after the application. Also, some pesticides evaporate more easily than others, as do some different formulations of the same pesticide.

Are certain pesticides more prone to drift? Fumigants are gaseous pesticides used to treat homes, storage bins, and soil before planting (Figures 3–4). Applicators inject them into soil or release them into buildings. Because they are gases, fumigants move easily through soil and air and will drift away from where they are applied unless they are confined. Various techniques are used. For example, applicators cover buildings with tarps and seal the edges to keep the fumigant in the structure. In fields, tarps are placed over the soil to minimize leakage. Over time, the gas slowly releases into the air. Because they are gases, fumigants are especially volatile. This means they are more likely to drift than other pesticides.

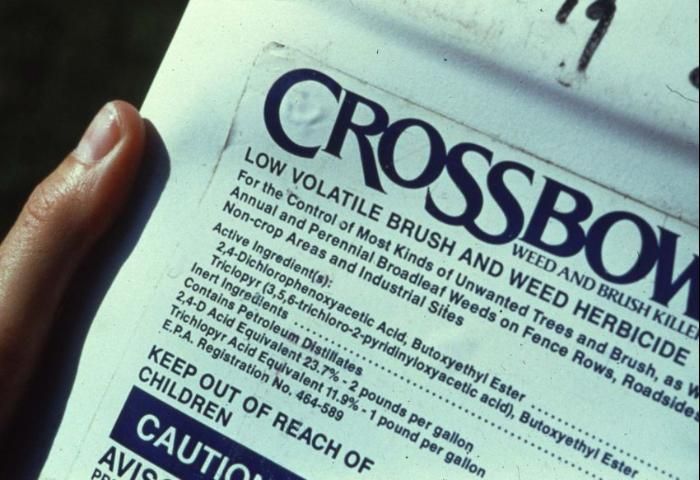

Some herbicide formulations are sufficiently volatile to cause plant injury from drift of vapor. For example, 2,4-D esters may produce damaging vapors, while 2,4-D amines are essentially nonvolatile and can drift only as droplets or dry particles. Herbicide vapor may drift farther and over a longer time than spray droplets.

Credit: UF/IFAS Pesticide Information Office

Credit: FDACS

Types of Pesticide Drift

What are the types of drift? In Florida, drift can also have legal meaning, because there are penalties for damage caused to sensitive crops by certain types of herbicides. Off-target movement can be in the form of:

- Spray droplet drift

- Vapor drift

- Particle (dust) drift

Spray Drift

Spray drift refers to the off-target movement of a pesticide during a liquid application. This is the result of small spray droplets being carried off-site by air movement. Spray drift occurs more frequently than the other two types of drift because almost all spray applications result in some off-target movement.

Vapor Drift

Vapor drift refers to the movement of pesticides as gaseous vapors from the target area. Some pesticides are volatile and can change readily from a solid or liquid into a gas under the right conditions. This most commonly occurs with high air temperatures. Pesticides that have volatilized into a vapor or gas may drift farther and for a longer time than they would have as spray droplets. Only those pesticides that are able to volatilize are susceptible to vapor drift. As air temperatures increase, the likelihood that these pesticides will volatilize and drift also increases.

Whenever possible, choose a pesticide formulated as a low-volatility product (Figure 5). Avoid applying volatile pesticides on hot days. Some products can even volatilize several hours after application, so beware if high temperatures are predicted for later in the day. Many products carry precautions against applying these products when temperatures are above 85°F or expected to reach 85°F. Remember to check label precautions for product-specific concerns about vapor drift.

Credit: UF/IFAS Pesticide Information Office

Particle Drift

Particle drift refers to the movement of solid particles from the target area by air during or just after an application. These solid particles may include pesticides formulated as dust or soil particles to which pesticides are attached. Some pesticides can remain active on soil particles for long periods after they are applied. If particles are blown off the target area, contamination or damage to sensitive areas can occur. Be sure to close all windows, vents, and turn off all circulating fans, forced-air heating systems, and air-conditioning units to prevent particle drift from nearby outdoor pesticide applications from entering a building.

Influencing Factors

Drift can occur in all forms of pesticide application: using agricultural airplanes, ground sprayers, airblast sprayers, or irrigation systems. In general, drift can be influenced by factors in one of these four categories:

- Spray solution characteristics

- Weather

- Application equipment

- Applicator decisions

Spray Characteristics

Understanding Droplet Size

The overwhelming factor influencing drift is droplet size. Small droplets do not have enough mass to drop quickly, so they remain airborne and exposed to air movement longer than larger droplets. Droplets are measured in microns, or micrometers (µm). One micron is equal to one millionth of a meter—the equivalent of 1/25,400th of an inch. Without magnification, particles less than 100 µm in diameter are practically invisible. Table 1 presents a relative perspective of droplet sizes.

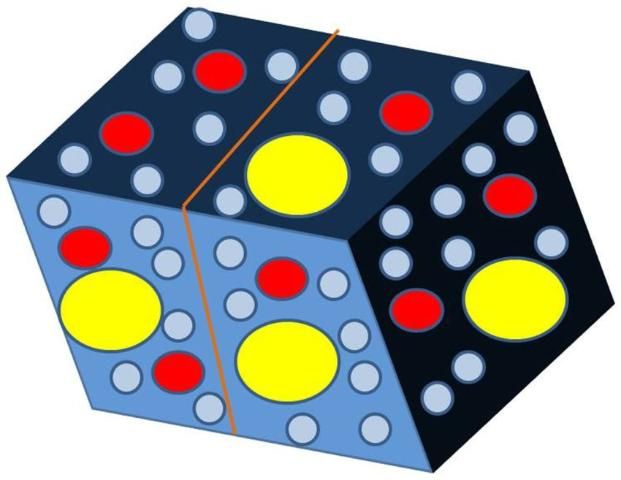

The term, volume median diameter (VMD) is used to indicate the relative droplet size of a volume of spray from a nozzle. A VMD of 400 µm means that half the volume of spray will be droplets that have a diameter of less than 400 µm, and the other half of the volume of spray will be droplets larger than 400 µm. Because smaller droplets have much less volume than larger droplets, most of the droplets will be smaller than the VMD (Figure 6).

Credit: UF/IFAS Pesticide Information Office

The larger the droplet, the faster it will reach its target. The distance that a droplet will travel downwind is a function of the height of release and wind speed and is inversely proportional to its terminal velocity. In other words, larger droplets will fall faster and be less exposed to wind. The higher a droplet is released and the stronger the wind, the greater the chance that a droplet will travel downwind and drift. Droplets that are smaller than 150 µm are considered drift-prone. Table 2 illustrates evaporation and deceleration of various droplet sizes. As an example, the fastest a droplet with a diameter of 20 µm will fall is 0.04 feet per second. Due to evaporation, the final droplet diameter will be approximately 7 µm in diameter, and it will fall less than one inch (its deceleration distance). Therefore, this droplet size is very susceptible to drift. In contrast, a 200 micron droplet falls at 2.4 feet per second, has a much larger final droplet size because it evaporates more slowly, and will fall at least 25 inches.

Droplet size becomes an issue when choosing a particular setup that will effectively reduce drift potential but still maximize coverage and penetration. In general terms, there is greater coverage from many small droplets than by a few larger droplets. The relationship between a droplet size and its volume is cubic; therefore, when comparing two droplets, for example a 250 µm and a 500 µm droplet, the latter carries 8 times more volume than the former. So using large droplets may be detrimental to some contact insecticides and fungicides that depend on coverage and penetration to be effective. Systemic herbicides can be effectively managed using large droplets since coverage and penetration are not so critical.

Pesticide Formulation

The viscosity, or thickness, of the liquid affects droplet size. The viscosity of a liquid is a measure of its resistance to flow. For example, mayonnaise is more viscous than water. As the viscosity of the liquid increases, so does the droplet size, thus reducing the potential for off-target movement. Formulations, such as invert emulsions, have a pasty consistency that aids in reducing drift. Other formulations produce some spray drift when water droplets begin to evaporate before reaching the intended target. As a result, these droplets become very small and light and may move from the target site. Thus, invert emulsions have less water loss, and more of the pesticide reaches the target. Volatile herbicides are more likely to have the potential of vapor drift.

Drift Retardants

Drift retardants are usually added to the spray mixture in order to increase the viscosity of the spray solution. Increasing the viscosity of the spray will reduce the number of small droplets (the ones smaller than 150 µm). There are several different drift retardants in the market with various degrees of efficacy. Although drift retardants are a tool to be used to decrease drift potential, their contribution is limited. Research has shown performance of drift retardants to be inconsistent. The best management practices to minimize drift potential are to correctly manage nozzle type, height, and operating pressure. Do not rely solely on drift retardants; there is no drift retardant that will eliminate drift.

Weather

Wind Speed

Wind speed is the most important weather factor influencing drift, but unfortunately, applicators have no control of it. High wind speeds will move droplets downwind and deposit them off target. On the other hand, dead calm conditions are never recommended because of the likelihood of temperature inversions (see the temperature inversion section of this article). Drift potential is lowest at wind speeds between 3 and 10 miles per hour—that is, a gentle but steady breeze, blowing in a safe direction away from sensitive areas.

The most effective way to check wind speed is to use a wind meter. Depending on the level of accuracy desired, models on the market range in price from around $20 to $300. To be accurate, wind meters should be used in places with no obstructions and not in places, such as near buildings or large trees, that may mask wind speed. Possible sources for obtaining spray equipment are listed in Table 3. Several of these vendors also carry wind meters.

Wind Direction

Wind direction will influence where off-target spray droplets will be deposited. A careful operator will try to apply pesticides whenever the wind is blowing away from sensitive areas, especially areas where people are working or children are playing. The use of a spray buffer downwind to protect sensitive areas and crops is an effective way to minimize drift.

Florida law should also be kept in mind regarding wind speed and direction. The Organo-Auxin Rule (discussed in-depth later in this article) was designed to protect sensitive crops from injury caused by drift of these herbicides. Depending upon the location of a sensitive crop, there are defined wind speeds and direction that may prohibit the application of these herbicides (presented at the end of this document).

Air Temperature and Relative Humidity

High air temperature and low relative humidity go hand-in-hand in creating a worst-case scenario for pesticide drift. Use special caution when relative humidity is below 50 percent and when temperatures are high. Drift is more likely during the hottest part of the day. Hot, dry conditions reduce droplet size through evaporation and thereby increase drift potential. Under these conditions, spray droplets can evaporate very fast and become more susceptible to wind forces. Air temperature can also influence atmospheric stability and off-target movement of spray droplets.

For typical applications with ground applicators, droplets of 50 µm and less will completely evaporate to a residual core of pesticide before reaching the target. Droplets greater than 200 µm will have no significant reduction in size before being deposited on the target. Evaporation of droplets between 50 and 200 µm is significantly affected by temperature, humidity, and other weather conditions. Some pesticide formulations are more volatile than others as described in the vapor drift section of this article.

Temperature Inversions

A temperature, or thermal, inversion is a condition that exists when the air at ground level is cooler than the temperature of the air above it. Temperature inversions occur naturally and are part of a daily atmospheric cycle, occurring in the early morning hours when the ground cools the air layer immediately above it. Such a condition is conducive for pesticide drift. Inversion conditions result when warmer air above traps cooler air located near the surface of the ground; this can be readily visible if dust or smoke rises little from its source and fails to dissipate (Figure 7). These conditions are more likely to occur in the early morning or evening. Applications made under low-wind conditions can sometimes result in more extensive drift than those made under high winds. Drift that occurs over long distances (over a mile) is most often the result of applications made under stable atmospheric conditions such as temperature inversions.

Credit: Wikipedia

Except in the case of temperature inversions, the early morning and evening are often the best times to apply pesticides because windy conditions are more likely to occur around midday when the temperature warms near the ground. This causes hot air to rise quickly and mix rapidly with the cooler air above it, favoring drift. During stable conditions, a layer of warm air can stay overhead and not promote mixing with colder air that stays below, closer to the ground. Inversions tend to dissipate during the middle of the day when wind currents mix the air layers. It is very important that applicators recognize thermal inversions and do not spray under those conditions.

Application Equipment

Nozzle Selection

Select the best nozzle type and size for each type of application you make and use drift-reduction nozzles. Remind yourself that nozzles are cheap compared to the cost of materials and cheap compared to the yield losses or litigation costs that can result from a poor application. Most improved nozzle designs really do have superior drop size characteristics. Almost all major agricultural nozzle manufacturers have recently introduced their version of low-drift nozzles.

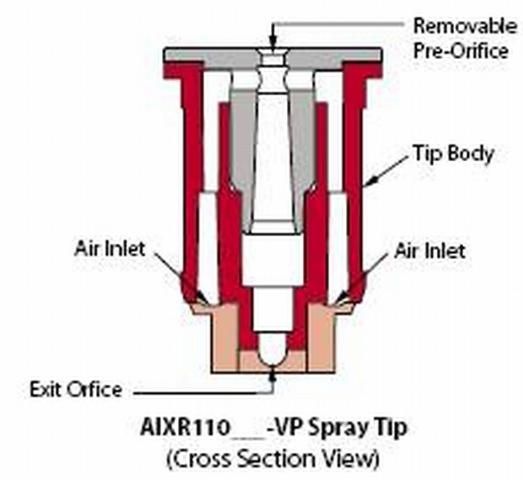

Drift-reduction nozzles are designed to create larger droplets at the same flow rate and operating pressure as comparable standard flat-fan nozzles. This has been accomplished by adding a pre-orifice to the nozzle tip assembly just ahead of the conventional discharge orifice, creating a venturi effect. Several different designs are currently being marketed and are commonly referred to as air-induction or venturi nozzles (Figures 8–9). The pre-orifice reduces pressure at the exit orifice, creating larger droplets to reduce drift significantly.

Credit: Spraying Systems Co.

Credit: Spraying Systems Co.

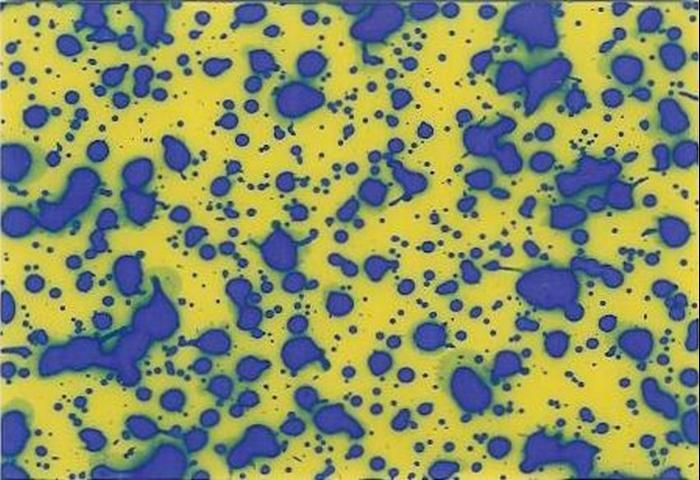

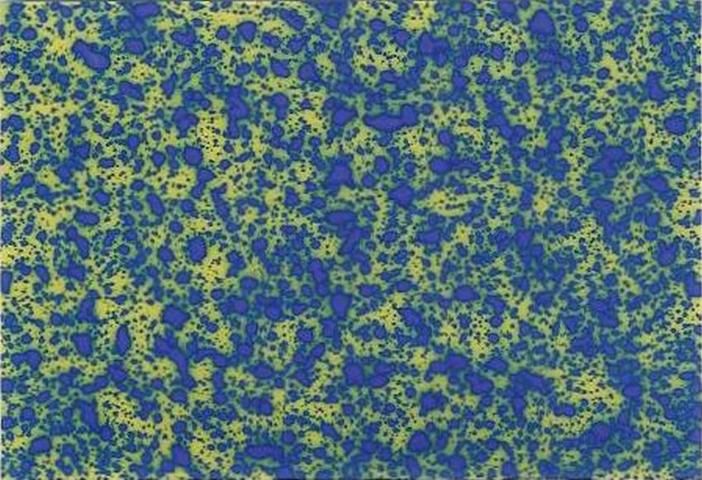

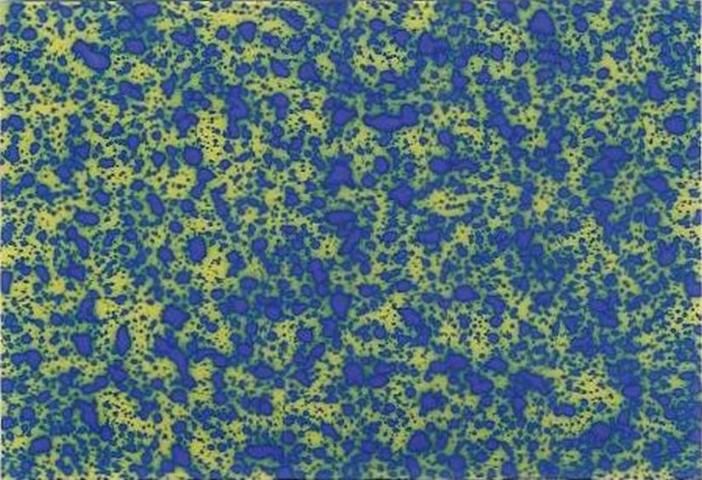

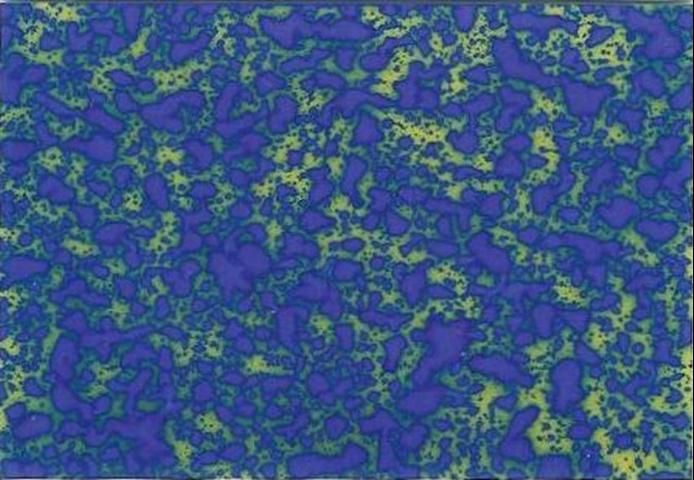

Research evaluating different nozzle types has shown air-induction nozzles to produce fewer small droplets compared to standard flat-fan nozzles (Table 4). The distance from the boom at which drift injury occurred was greater with the flat-fan tips than the other nozzle types. Using water-sensitive cards allows visual observation of relative droplet size under varying conditions. For example, the droplets produced by an air-induction nozzle are compared to those of a standard flat-fan nozzle (Figures 10–11). As droplet size decreases, the number of droplets prone to off-target movement increases.

Credit: J. A. Ferrell, UF/IFAS

Credit: J. A. Ferrell, UF/IFAS

To help applicators select nozzles according to droplet size, spray equipment manufacturers are including drop size charts with their respective catalogs and with websites that use color codes set by the American Society of Agricultural and Biological Engineers (ASABE). Refer to Table 3 for a listing of suppliers of nozzles and other spray equipment. Pesticide labels state specified droplet sizes to use when applying the product (for an example [found on an herbicide label], see Information on Droplet Size below; credit: CDMS). General droplet spectra categories and recommendations for various pesticide types or uses according to ASABE are shown in Table 5.

INFORMATION ON DROPLET SIZE:

The most effective way to reduce drift potential is to apply large droplets. The best drift management strategy is to apply the largest droplets that provide sufficient coverage and control. Applying larger droplets reduces drift potential but will not prevent drift if applications are made improperly or under unfavorable environmental conditions (see Wind, Temperature and Humidity, and Temperature Inversions below).

Uniform, thorough spray coverage is important to achieve consistent weed control. Select nozzles and pressure that deliver MEDIUM spray droplets as indicated in nozzle manufacturer's catalogs and in accordance with ASABE Standard S-572. Nozzles that deliver COARSE spray droplets may be used to reduce spray drift provided spray volume per acre (GPA) is increased to maintain coverage of weeds.

Boom/Nozzle Configuration

For ground sprayers, keep the boom close to the target (soil surface or canopy) in accordance with the nozzles being used. Nozzles with wider spray angles allow lower boom heights. Do not spray at greater heights than those recommended by the spray tip manufacturer.

The Spray Drift Task Force (SDTF) is a team of pesticide industry personnel assembled to conduct research on pesticide drift in response to the Environmental Protection Agency's (EPA) concern about drift. For aerial applications, according to the SDTF, the boom length should be maintained at 70% or less of the wingspan with a target boom height between 8 and 22 feet. The angle of the nozzles in relation to the direction and speed of travel affects droplet size.

For airblast sprayers in Florida, it has been a common practice to direct 2/3 of the spray volume to the upper half of the tree and 1/3 to the lower half. However, this practice is no longer recommended when spraying small trees or using large airblast sprayers. The 2/3–1/3 nozzle arrangement has shown no significant improvement in overall spray deposition or pest control as compared to 1/2–1/2 nozzle arrangement. Sprayer air deflectors, nozzle orientation, and number of nozzles should be adjusted to match the size and shape of the canopy and minimize spray wastage. For low-volume rates (less than 100 gpa), reducing the number of nozzles and using smaller disc and core sizes, rather than spraying at higher ground speeds, may improve spray deposition. For high-volume rates (greater than 250 gpa), increasing the number of nozzles and spraying at higher ground speeds, instead of using fewer large disc and core sizes, may give higher deposition efficiency. Deposition efficiency of midvolume rates (100–250 gal/acre) is less sensitive to these application variables.

Spray Height

The spray release height will influence how far droplets will travel downwind. This may not be as critical for ground sprayers, but it is very important for aerial application. With aerial applications, pilots should try to maintain an optimum distance from the crop, generally with nozzles about 8 feet above the ground or crop, compared with forestry or rangeland applications that are sometimes made at 20 feet or higher.

Research data compiled by the SDTF show that when nozzle height is changed from 8 feet to 22, approximately 2.5 times more drift is deposited 25 feet downwind. With ground applications, nozzles with wider spray angles allow lower boom heights. Any additional distance will give droplets an opportunity to be influenced by wind and be deposited off target.

Spray Pressure

Pesticide product labels contain generic statements concerning the use of the lowest possible spray pressures while achieving adequate droplet size and coverage. In general, higher pressures will produce more fine droplets and increase the drift potential of an application. Nozzle tips are available that, when operated at relatively high spray pressures, will produce coarse to very coarse droplets as compared to other designs of nozzles that would produce more fine droplets at the same pressure.

Pressure has been demonstrated to not be an effective way to increase coverage and canopy penetration. Furthermore, increasing pressure is not an efficient method to make significant increases in output volume. In order to double output, pressure would have to be increased fourfold. For example, increasing flow from 5 gallons per acre (gpa) at 10 pounds per square inch (psi) to 10 gpa would require that pressure be increased to 40 psi. Such an increase would increase the number of fine droplets produced as well. When significant changes in output volume are necessary, changing to a nozzle tip with a larger orifice is most practical. Pressure gauges should be checked periodically for accuracy.

Carrier Volumes

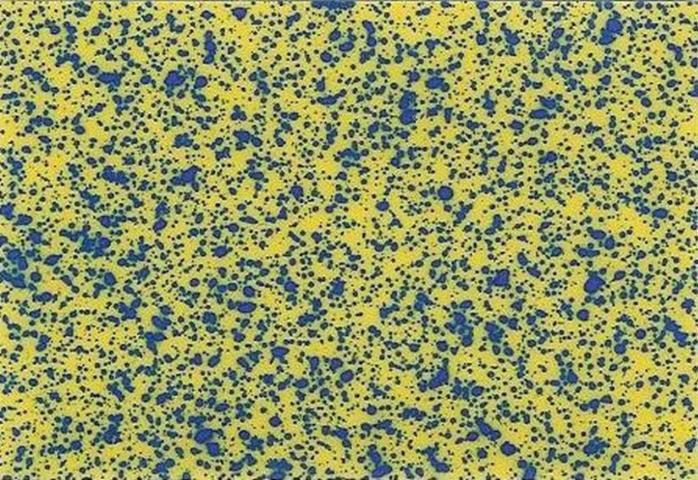

Although some product labels require low volumes, there are others that you may select with a higher volume that allows the use of larger nozzles, which produce larger, less drift-prone droplets when operated at the correct pressure. Research at the University of Florida has shown that increasing carrier volume with the same nozzle type can also increase spray coverage. Using an extended-range nozzle tip, coverage increased from 53.3% when applied at 10 gallons per acre to 93.0% when applied at 20 gallons per acre, and 99.0% when applied at 30 gallons per acre (Figures 12–14).

Credit: J. A. Ferrell, UF/IFAS

Credit: J. A. Ferrell, UF/IFAS

Credit: J. A. Ferrell, UF/IFAS

Application Speed

Site conditions will ultimately determine application speed, but a speed that can be maintained without pushing the pressure limits of the nozzle and that does not cause the boom to bounce is optimal. Higher speeds are not only harder on equipment and difficult to maintain but also result in enough air movement to cause some drift. Increased operating speeds can cause the spray to be diverted back up into upward wind currents and vortexes behind the sprayer, which trap small droplets and can contribute to drift.

Calibrate the Sprayer and Replace Worn Nozzles

Calibration is the process by which the amount of pesticide being applied per a unit of area is determined. Calibrate your pesticide applicators on a regular basis to ensure that output from each nozzle is consistent and the desired application rate is achieved.

Worn nozzles produce spray patterns and poor droplet distributions that result in poor coverage, increased drift, or both. Some nozzle materials wear faster than others, and applying certain abrasive pesticide formulations, such as wettable powders, increases the rate of wear.

Shielded Sprayers

Partially covering a sprayer boom with a shield has been shown to be helpful in reducing spray drift (Figure 15). Researchers have conducted wind tunnel tests with a shield placed near a nozzle to determine the effect on the path droplets follow after they are released from the nozzle. Results from laboratory tests conducted at the University of Missouri indicated that a mechanical shield could reduce spray-drift deposit by up to 70%. Tests conducted in Ohio under field conditions generally showed reduction in drift deposits of up to 65% with a shield. Some manufacturers of equipment offer shielded sprayers for specific types of applications, such as for use on golf courses (Figure 16).

Credit: UF/IFAS Pesticide Information Office

Credit: UF/IFAS Pesticide Information Office

Applicator Decisions

Under a given spray situation, any one of the previously mentioned factors may be the most critical in reducing drift hazards. Ultimately, it is the applicator's job to determine the critical factor and to take precautions against it. To minimize concerns to neighbors and the environment, applicators must recognize sensitive areas around each field before beginning an application. By exercising sound judgment regarding both equipment and weather factors relative to each application, applicators can minimize drift potential in nearly every case.

Follow Label Directions

If there are specific conditions spelled out on a product label in regards to drift, they should be the first concern.

The following are drift mitigation statements as seen on a pesticide product label (CDMS):

Wind Speed

Do not apply at wind speeds greater than 15 mph. Only apply this product if the wind direction favors on-target deposition and there are not sensitive areas (including, but not limited to, residential areas, bodies of water, known habitat for nontarget species, nontarget crops) within 250 feet downwind. If applying a Medium spray, leave one swath unsprayed at the downwind edge of the treated field.

Temperature Inversions

If applying at wind speeds less than 3 mph, the applicator must determine if: a) conditions of temperature inversion exist or b) stable atmospheric conditions exist at or below nozzle height. Do not make applications into areas of temperature inversions or stable atmospheric conditions.

Susceptible Plants

Do not apply under circumstances where spray drift may occur to food, forage, or other plantings that might be damaged or crops thereof rendered unfit for sale, use or consumption. Susceptible crops include, but are not limited to, cotton, okra, flowers, grapes (in growing stage), fruit trees (foliage), soybeans (vegetative stage), ornamentals, sunflowers, tomatoes, beans, and other vegetables, or tobacco. Small amounts of spray drift that might not be visible may injure susceptible broadleaf plants.

Other State and Local Requirements

Applicators must follow all state and local pesticide drift requirements regarding application of organo-auxin herbicides, such as 2,4-D. Where states have more stringent regulations, they must be observed.

Know the Right Conditions

If winds are blowing towards a sensitive area, do not spray at any wind speed. Ideally, winds should be in the range of 3 to 9 mph. Generally, pesticide should not be sprayed when winds exceed 10 mph. Use caution when winds are light and variable, especially when applications are to be made near susceptible vegetation. Be aware that very calm conditions could indicate the presence of a temperature inversion, especially during the early morning. Inversions favor pesticide drift. Also, use special caution when relative humidity is low and when temperatures are high. Drift is much more likely during the hottest part of the day as those conditions are conducive for drops to evaporate, form smaller droplets, and drift off target.

Buffer Zones

Buffer zones are untreated areas between the treatment site and sensitive areas. It is the area where no pesticide application should occur and is designed to catch off-target spray on their surfaces. If buffers are open areas, they will depend on distance to allow spray materials to settle. This means they need to be relatively wide areas and will be more effective if vegetation or other surfaces are present.

Keep Application Records

Keep records of air temperature, relative humidity, wind speed, and wind direction. These records, as well as equipment and application information, may be very helpful in dealing with drift-related litigation. The Florida Pesticide Law requires licensed pesticide applicators to maintain records relating to the application of all restricted use pesticides. No one type of recordkeeping form is required; any recordkeeping form is acceptable as long as the required data are included. This allows applicators flexibility to fit the recordkeeping requirements into their current recordkeeping scheme. FDACS produces and has made available a Suggested Pesticide Recordkeeping Form. The form, also translated into Spanish, provides additional data entry areas for meeting Worker Protection Standard compliance. It may be obtained by calling FDACS at (850) 488-3314 or online at https://www.fdacs.gov/content/download/2990/file/SPR.pdf.

Be a Good Neighbor and Communicate

Communicate with your neighbors and maintain a good relationship to prevent disagreements and misunderstandings. Many residents who have relocated into rural agricultural production areas have no understanding of where their food comes from and how important its production is to Florida's economy. Besides communicating with neighbors about the importance of agricultural production, some simple examples of good neighbor practices that growers could instill include:

- Letting neighbors know when pesticide applications will be made and, if possible, make applications during a time in which the fewest neighbors could be affected.

- Letting neighbors know what you are applying. Many people do not understand that fertilizer application and the use of biological pesticides will not harm them.

- Sharing produce and agricultural production information with neighbors.

- Working with new developments to have buffer zones and buffer plantings included in their development plan. Even if they only provide half of the buffer area, it will save you from taking additional field space out of production.

- If you are near a school, use your agricultural operation as an opportunity to inform future voters about the importance of agriculture. If possible participate in the school's Florida Ag in the Classroom reading days (https://faitc.org) or offer to meet with the PTA.

Drift and Florida Law

Chapter 487 of the Florida Statutes: "It is unlawful for any person to apply a pesticide directly to, or in any manner cause any pesticide to drift onto, any person or area not intended to receive the pesticide."

Florida's Organo-Auxin Herbicide Rule

Due largely to phenoxy herbicide applications in South Florida on sugarcane and drift or volatilization to nearby tomato crops and their subsequent destruction, FDACS enacted the Organo-Auxin Herbicide Rule (Table 6). This rule applies to the application of organo-auxin herbicides anywhere within the state as there are many agricultural plants sensitive to organo-auxin herbicides (Figure 17). A suggested recordkeeping form developed by FDACS is available for applicators of organo-auxin herbicides to record their data. The form may be downloaded here: https://forms.fdacs.gov/13328.pdf.

Credit: UF/IFAS Pesticide Information Office