Silicon, a Beneficial Nutrient for Sugarcane

This publication is intended primarily for Florida sugarcane (Saccharum spp.) growers, but it may also be useful to researchers and others interested in sugarcane nutrition. The publication presents recommendations for calcium silicate application for sugarcane grown on Florida mineral soils along with supporting information. Silicon (Si) is considered a beneficial nutrient for sugarcane, although it is not classified as an essential nutrient for plant growth. Sugarcane yield increases have occurred in Florida and in many other parts of the world with applications of calcium (Ca) silicate to soils low in soluble Si. Yield increases with Si application may be attributed to various mechanisms, including increased resistance to diseases and insects, increased mechanical strength of cells, and reduction in water loss through evapotranspiration (Datnoff et al. 1997; Keeping et al. 2013; Meyer and Keeping 2000).

UF/IFAS recommendations for Si fertilization on Florida Histosols (organic soils) have been published and are available at https://edis.ifas.ufl.edu/publication/SC092. UF/IFAS recommendations have not previously been available for sugarcane grown on mineral soils. In Florida, 29% of sugarcane production is on mineral soils (115,000 out of 400,000 acres) (VanWeelden et al. 2021). Although these mineral soils are sands and therefore have a very high total Si content, the soluble Si content is low due to leaching from high annual rainfall and low organic matter and clay contents in these soils. Sugarcane field trial results with Si rates were used to develop Ca silicate recommendations for sugarcane grown on mineral soils in Florida, based on 0.5 N acetic acid-extractable soil Si.

Sugarcane Yield Responses to Calcium Silicate

Two trials were conducted on mineral soils examining sugarcane yield response to Ca silicate application (Table 1) (McCray and Ji 2018). In these experiments, the Si source used in developing recommendations was an electric furnace Ca silicate slag produced as a by-product of elemental phosphorus production. This slag contained approximately 20% Si on a dry weight basis, and is the same material used to develop recommendations for organic soils (McCray et al. 2011).

Table 1. Basic soil and experimental information for each site in the calcium silicate rate study.

There were significant increases in tons cane/acre (TCA), tons sugar/acre (TSA), stalk weight, and stalks/ft of row with Ca silicate application at both sites (Table 2). At Site 1, dolomite was also included as a treatment, but there were no differences in any harvest parameter with dolomite application. Calcium silicate application only influenced sugarcane tonnage and did not affect sucrose concentration (lb sugar/ton cane). Calcium silicate requirements for both sites were determined to be 3 tons/acre and 1.9 tons/acre, respectively (McCray and Ji 2018), corresponding to initial soil test values of 21 g Si/m3 and 46 g Si/m3 at these locations (Table 1). These Ca silicate recommendations for each location also maintained leaf Si concentration within the optimum range (>0.6%) (McCray and Mylavarapu 2020) for the plant cane and first ratoon crops (McCray and Ji 2018).

Table 2. Harvest data for Sites 1 and 2 including tons cane/acre (TCA), tons sugar/acre (TSA), lb sugar/ton cane, stalk weight, and stalks/ft row.

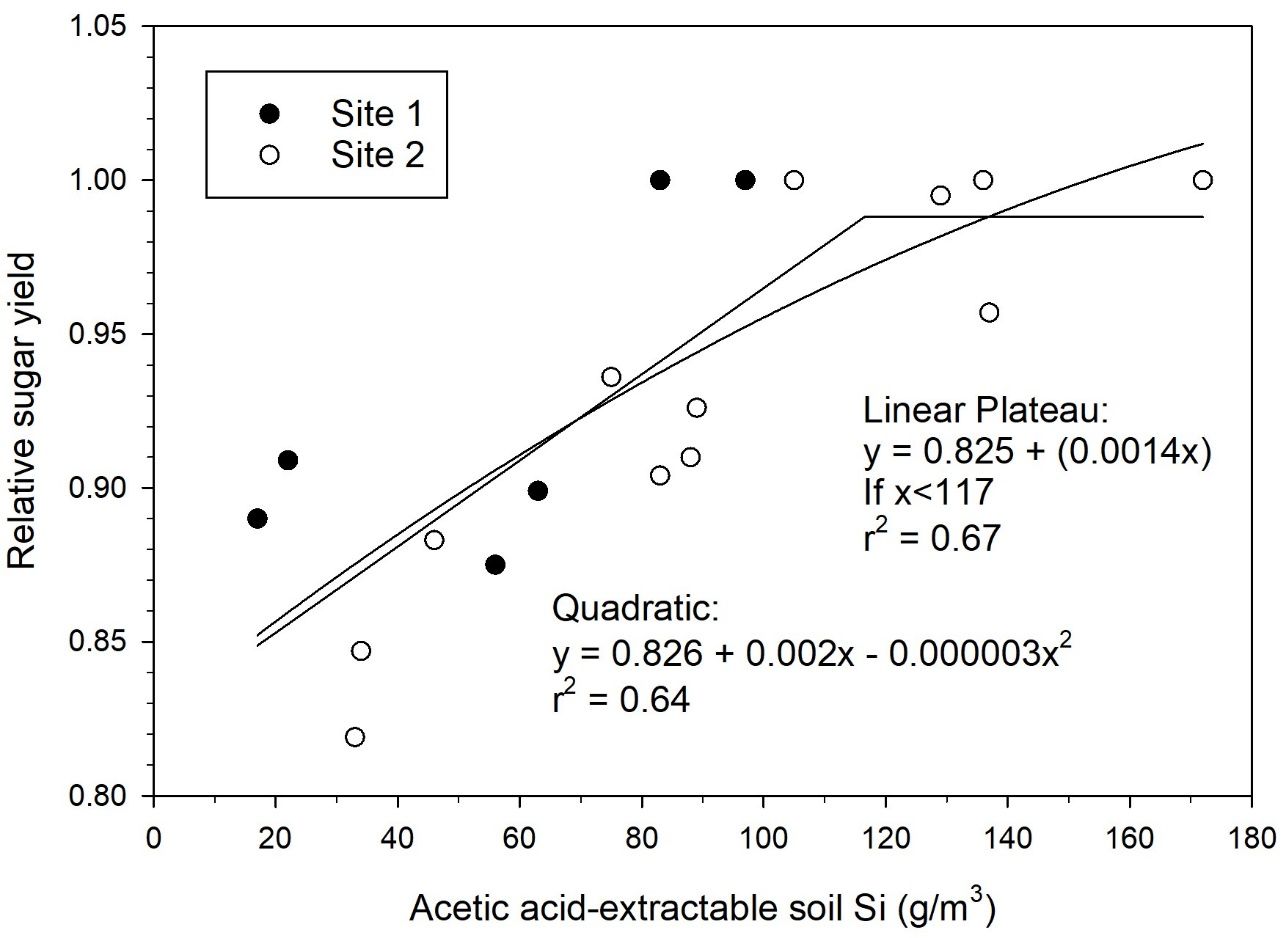

Figure 1 shows the two most significant regression models relating acetic acid-extractable soil Si and relative sugar yield. The linear plateau model indicates that optimum sugarcane yield was achieved with a minimum of 117 g Si/m3. This compares to a minimum acetic acid-extractable value of 25 g Si/m3 required for organic soils (McCray et al. 2011), indicating that a separate calibration is required for mineral soils.

Credit: McCray and Ji (2018)

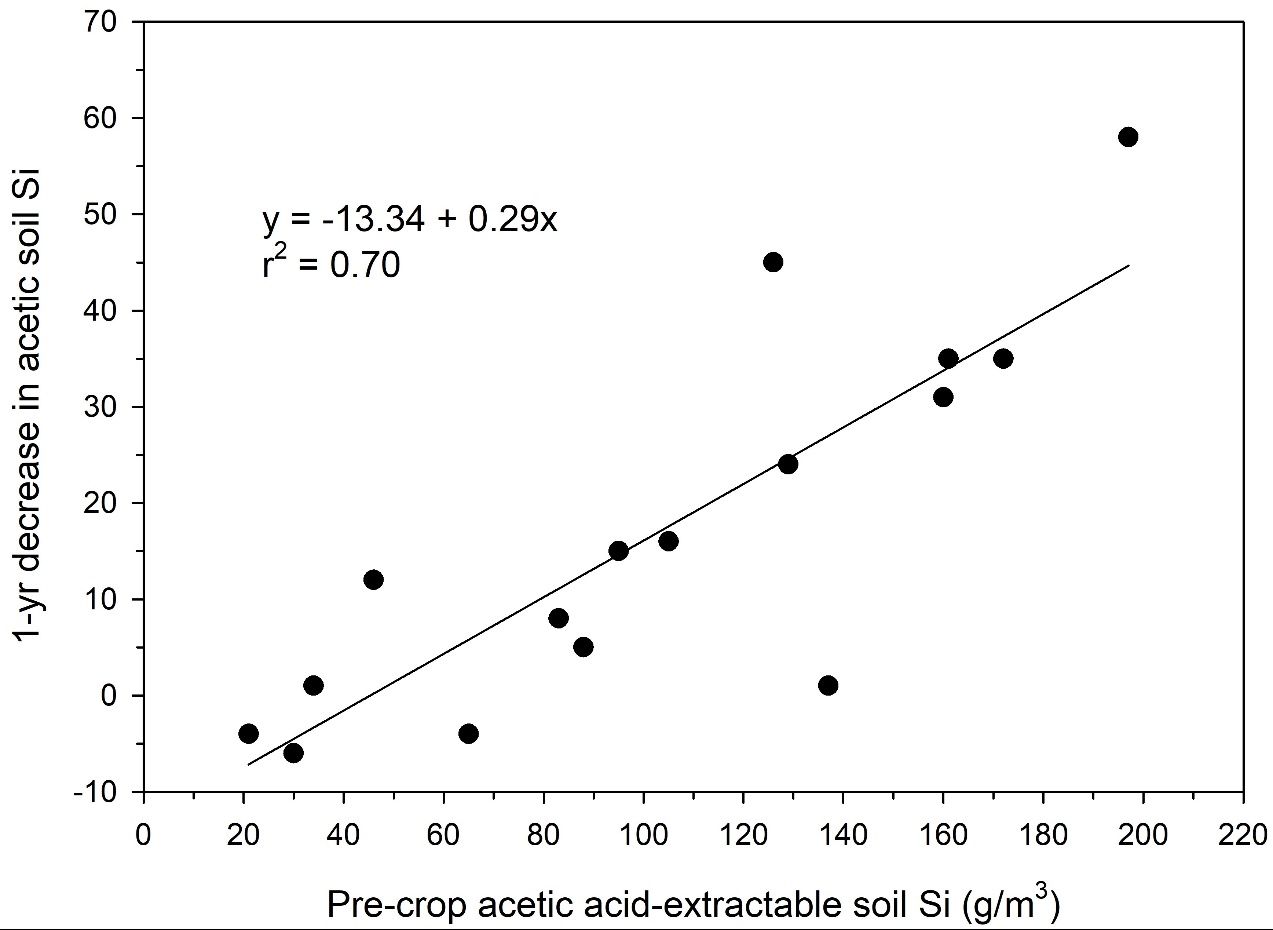

Additional field trials have confirmed the yield response shown in Figure 1. In two ongoing field trials, the greatest yield response has been determined with soil test values < 50 g Si/m3. However, there was some yield response with soil test values between 100 g Si/m3 and 120 g Si/m3. Because these soil test values are from samples taken after harvest of each crop, it is necessary to estimate the reduction of soil test Si during that crop year to set up a useful calibration of preplant soil values for Ca silicate application. Results from field Si trials were used to relate the magnitude of a one-year decrease in acetic acid-extractable Si to pre-crop soil Si (Figure 2). Although there is variability in individual values, this relationship indicates that for a sugarcane crop on sand soils, acetic acid-extractable Si values of 100 g/m3 and 150 g/m3 would be reduced in one year to 84 g/m3 and 120 g/m3, respectively.

Credit: UF/IFAS

Calcium Silicate Recommendations

Table 3 shows calcium silicate recommendations for sugarcane grown on Florida mineral soils. Calcium silicate is recommended for acetic acid-extractable soil Si values up to 150 g/m3, which uses the 117 g/m3 value from Figure 1 in addition to the approximate one-year soil test reduction of 30 g/m3 (from Figure 2) to estimate preplant soil Si. Similarly, soil test values in Figure 1 can be adjusted to estimate preplant values across the entire range using Figure 2. A maximum rate of 3 tons Ca silicate/acre is recommended for lowest soil test values. This is also the highest rate recommended for organic soils. Calcium silicate requirements for initial soil test values in field Si trials were used to determine specific soil test ranges corresponding to each Si recommendation. These recommendations are for preplant broadcast application and disk-incorporation of Ca silicate and are intended to provide an adequate supply of Si for three crop years. Silicon amendment requirement was determined by evaluating the required rate in relation to initial soil test Si values needed to maintain yield response and sufficient leaf Si concentration for a typical three-year crop cycle. Additionally, these recommendations are based on application of Ca silicate with approximately 20% Si (42% SiO2). Adjustments may be necessary in application rates for materials with differing Si contents or Si solubility.

Table 3. Calcium silicate recommendations for sugarcane grown on Florida mineral soils.

References

Datnoff, L. E., C. W. Deren, and G. H. Snyder. 1997. “Silicon Fertilization for Disease Management of Rice in Florida.” Crop Protection 16(6): 525–531. https://doi.org/10.1016/s0261-2194(97)00033-1

Keeping, M. G., J. H. Meyer, and C. Sewpersad. 2013. “Soil silicon amendments increase resistance of sugarcane to stalk borer Eldana saccharina Walker (Lepidoptera: Pyralidae) under field conditions.” Plant and Soil 363(1-2): 297–318. https://doi.org/10.1007/s11104-012-1325-1

McCray, J. M., and S. Ji. 2018. “Sugarcane Yield Response to Calcium Silicate on Florida Mineral Soils.” Journal of Plant Nutrition 41:2413–2424. https://doi.org/10.1080/01904167.2018.1510520

McCray, J. M., and R. Mylavarapu. 2020. “Sugarcane Nutrient Management Using Leaf Analysis.” SS-AGR-335. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/AG345

McCray, J. M., R. W. Rice, and L. E. Baucum. 2018. “Calcium Silicate Recommendations for Sugarcane on Florida Organic Soils.” SS-AGR-350. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/SC092

Meyer, J. H., and M. G. Keeping. 2000. “Review of Research into the Role of Silicon for Sugarcane Production.” Proceedings of the South African Sugar Technologists Association 74:29–40.

VanWeelden, M., S. Swanson, W. Davidson, M. Baltazar, and R. Rice. 2021. “Sugarcane Variety Census: Florida 2020.” Sugar Journal 84(2): 6–15.