What is poultry manure and litter?

Poultry manure is the organic waste material from poultry consisting of animal feces and urine. Poultry litter refers to the manure mixed with some of the bedding material or litter (wood shavings or sawdust) and feathers (Figure 1). This publication deals with litter. Poultry houses are regularly cleaned out by removing a thin layer of the bedding along with the manure (Figure 2). The most common source of poultry litter in Florida is from broiler houses (Figure 3). Most of the litter from poultry houses in northern Florida is composted under a covered structure for several weeks to start the decomposition process. Poultry litter can be used for vegetable production in Florida. However, fresh animal manures are known to harbor human pathogens, such as E. coli or Salmonella spp., and therefore some restrictions guide its use in vegetables, especially for organic vegetable production. Factors that mitigate the possibility of vegetable contamination include the use of composted manure instead of fresh manure, incorporating the manure in the soil ahead of planting, and using polyethylene mulch to cover the soil. More information on the food safety issue and poultry manure is presented below.

Credit: G. Hochmuth

Credit: J. Jones

Credit: G: Hochmuth

Poultry manure is an excellent fertilizer material because it contains essential plant nutrients, especially nitrogen (N), phosphorus (P), and potassium (K). These nutrients plus others come largely from the bird feces. Manures decompose (mineralize) in the soil releasing nutrients for crop uptake. If poultry litter is readily available locally, it can help reduce fertilizer costs in vegetable production. The vegetable producer should conduct a cost analysis between litter and chemical fertilizers to determine the economic benefit. A listing of nutrient concentrations in typical poultry manure or litter is presented in Table 1.

In addition to supplying nutrients, poultry manure or litter serves as a soil amendment increasing the soil organic matter content. The added organic matter increases the moisture holding capacity of the soil, lowers soil bulk density, and improves overall soil structure, thus increasing the efficiency of the crop production and irrigation management. Organic matter accumulation in the soil will depend largely on the type of manure or litter, rainfall, and on soil type and temperature. There is little information about how rapidly poultry litter will mineralize in sandy soils under mulched-vegetable production systems in Florida.

What plant nutrients are typically found in poultry litter?

Some amount of all essential plant nutrients can be found in poultry litter, because the manure is waste from the plant-based feedstuffs consumed by the birds. The key to proper use of manures as plant nutrient sources comes in the knowledge of the nutrient content and the nutrient requirements of the crop to be fertilized with nutrients from manure or litter. Many laboratories offer manure nutrient analyses to determine specific nutrient contents and make recommendations for use as a fertilizer for vegetables. These analyses can be done at the University of Florida Livestock Waste Testing Laboratory on the campus of the University of Florida, in Gainesville: http://soilslab.ifas.ufl.edu. Litters are organic materials and are similar to mixed chemical fertilizers in that the manure supplies an array of nutrients, some of which may not be required by a crop on a particular soil, or may be in insufficient supply from the manure alone. Phosphorus (P) will build up in most soils where manures are used frequently, because all manures contain P and most soils in Florida retain much of the P applied. Poultry litter might not be the most suitable fertilizer chosen for a soil in a watershed where there are concerns about runoff from existing high levels of soil-P.

The actual nutrient content of manures may vary from one livestock operation to another or even over time at a single operation. Factors that contribute to this variation include the number of animals per operation, composition of the animal feed ration, design of the waste management system including the presence of intermixed bedding materials (litter), and season. Therefore, livestock manures should be sampled and analyzed to determine their nutrient concentrations before a sound nutrient management plan can be designed and implemented. More information on manure sampling and analysis can be found at https://edis.ifas.ufl.edu/ss495.

What are some considerations of using poultry litter in vegetable production?

Food safety considerations. In addition to using poultry manure for the plant nutrient value, there are food safety considerations when using poultry manure in the production of fruits and vegetables. Fresh poultry manure is known to harbor human pathogens such as E. coli and Salmonella spp. Food safety regulations now implemented by the US Food and Drug Administration through the Food Safety Modernization Act restrict how and when manures can be used in the production of fresh fruits and vegetables (http://www.fda.gov/Food/GuidanceRegulation/FSMA/ucm304045.htm). Furthermore, certain wholesale buyers may impose even further restrictions on how fresh manure is to be used in the production of fruits and vegetables that they will purchase. A third-party food safety audit may be required prior to selling the product. If the manure source is composted and there is documentation of an approved composting procedure, the restrictions are generally less for the composted manure products than for fresh animal manures. Growers should check with the buyers of their fruits and vegetables to determine their food safety requirements or contact their County Extension agents to seek more information regarding food safety regulations with respect to using manure in crop production.

Environmental considerations. Utilizing poultry manure as a fertilizer is recommended as a best management practice (BMP) when applied to meet crop nutrient needs in conjunction with appropriate soil tests. As a BMP, using poultry litter in crop production removes the manure from concentrated areas (poultry operations) where there is potential for nutrient runoff. The most common procedure for determining the amount of manure to add per acre is to consider the manure's N content and the N needs of the crop. In areas where off-site P movement (leaching or run-off) can lead to eutrophication of surface waters, P rather than N should be the factor determining application rate of manure.

How much of the fertilizer requirement should be applied from manure? Typically soil testing labs recommend supplying up to 50% of the crop nutrient requirements (for example, nitrogen) from manure. This is a good rule of thumb, but can be modified where multiple crops will be grown in succession on the same mulched bed. There are several challenges with attempting to supply 100% of the fertilizer from manure. Since the manure releases about 50% of its nutrients upon mineralization within the first year, one would need to apply high rates of manure to get all the crop nutrient requirements for that year from manure alone. Then there would be significant nutrient amounts left to mineralize over the intervening non-crop period. These nutrients could be lost to runoff or leaching unless there was a cover crop planted after mulch removal, or another crop planted immediately on the mulched beds. Also, if the C:N ratio of the applied litter is high, the nutrient release can be delayed or limited. The user should inquire about the degree of composting and how mature the compost is; generally, composting speeds the decomposition and availability of nutrients. Variations in composting periods and among sources make laboratory analyses important.

Economic considerations. Poultry manure is considered a "low-analysis" nutrient source. That is, it contains low concentrations of plant nutrients. Therefore, costs for moving and applying manure are typically not favorable compared with high-analysis chemical fertilizers. Economic considerations for using manure will include: its overall nutrient value, the proximity of the source to the fields where it will be applied, and other values to the manure that are not available from chemical fertilizers (organic matter for example). Another consideration might be the longevity of the manure's nutrient supplying capacity. In this regard, the manure might be similar in function to a controlled-release fertilizer, therefore obviating the need for (and costs associated with) nutrient side-dressing or injection into a drip irrigation system.

Mineralization rates in sandy soils. Since manures and litters are organic materials, they will decompose or mineralize in aerated sandy soils such as we have in Florida. Mineralization rates of manure materials in warm, moist, sandy soils are rapid, and this factor must be taken into account when calculating the application rate for crop production. Laboratories typically take into account the mineralization rate in soils when making recommendations for manure application. Most labs assume that 50% of the manure will be mineralized and release nutrients in the first year, the remaining nutrients will be held in the organic matter for later release at about 50% of the remaining amounts each year. These release rates were developed in northern states and no such rates have been developed for Florida. Based on preliminary research conducted at the UF/IFAS North Florida Research and Education Center (NFREC), near Live Oak, the rates of mineralization for Florida appear to be greater than those for northern states, probably nearly complete over a three-year span. The mineralization and release of N from manures is of particular concern where nitrate contamination of water bodies is an issue. If manure were applied at rates that would release more N than a crop could remove, then nitrate could be lost to leaching to the groundwater. This environmental aspect is becoming an important consideration for regular testing of manures and their application at appropriate rates for crop utilization. Development of the nutrient management plan is a sound investment to avoid environmental issues.

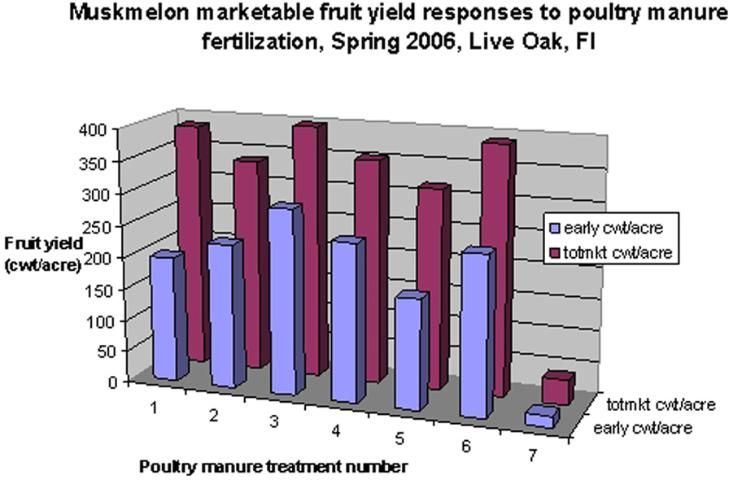

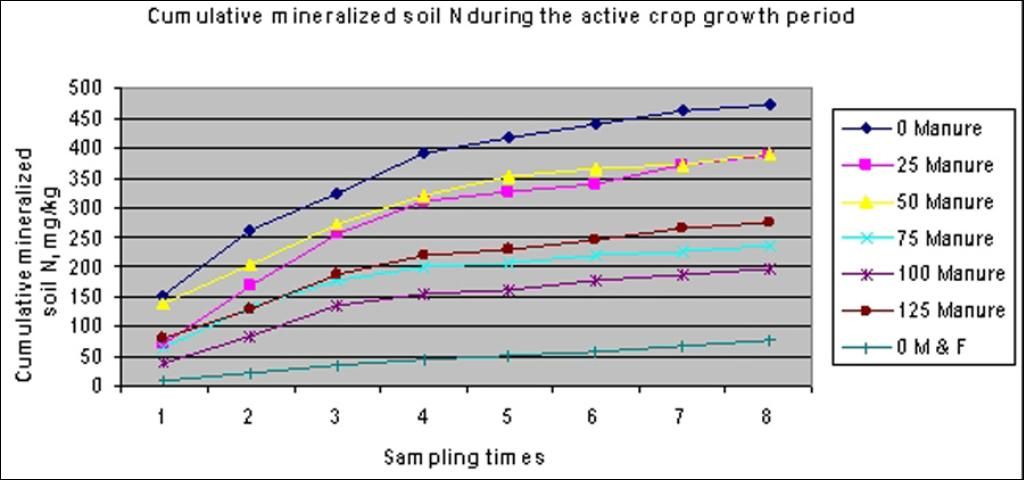

Several seasons of research, funded by the Florida Department of Agriculture and Consumer Services, Office of Agricultural Water Policy, has been completed by the UF/IFAS NFREC–Suwannee Valley near Live Oak, to evaluate the mineralization rate for typical poultry manure with litter (Figure 3). The treatments are presented in Table 2 and the application of manure shown in Figure 4. Crop responses are shown in Figure 5. The results from all three seasons were similar. The results from the final season, 2006, showed that poultry manure can be used successfully for mulched vegetable production. Applying 25% to 100% of the total N needs of the crop from manure resulted in similar crop yields (Figure 6). As the proportion of poultry manure or litter used to supply the total N exceeded 25 to 50%, greater amounts of N remained in the soil to be mineralized late in the season (Figure 7). Greater rates will risk leaching losses of N from unmineralized manure late in the season or after the crop season is completed.

Credit: G. Hochmuth

Credit: G. Hochmuth

Other Examples of Research with Poultry Manure in Vegetable Production in Florida

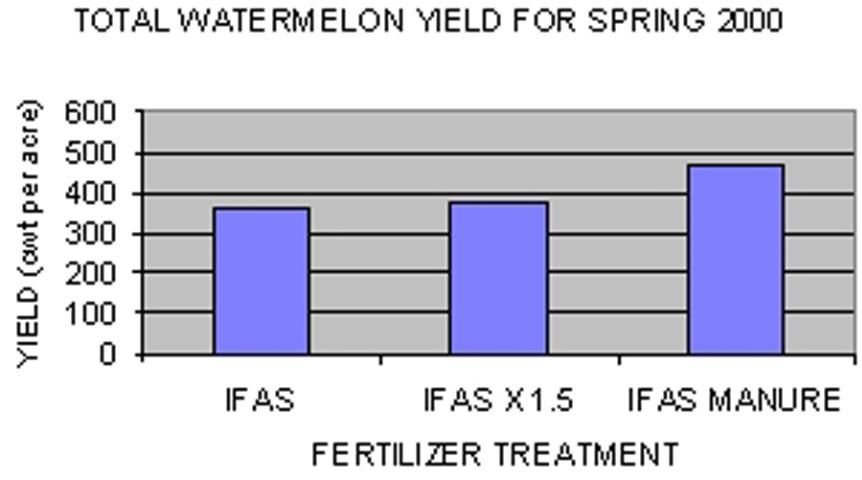

Poultry manure applied at rates recommended from a manure analysis can be used successfully to grow vegetables. The following graph presents the results of a study conducted at the UF/IFAS NFREC–SV near Live Oak, FL in 2000 (Figure 8). The project compared watermelon production with three fertilizer treatments: (1) the UF/IFAS recommended rate (150 lb/acre N), (2)1.5 x the UF/IFAS recommended rate, and (3) the UF/IFAS recommended rate with 50% of the N from manure. The third treatment resulted in the highest fruit yield.

Other studies conducted in the 1990s with eggplant, cabbage, and squash (Hochmuth et al. 1993, 1997) showed poultry manure can be successfully used as a source of nutrients for mulched vegetables. Mineralization rate is rapid so that little nutrient value remains for a second crop, if the recommended rate of manure was used for the first crop.

Steps for Using Manure in a Mulched-Bed System for Vegetable Production

Step 1. Determine a source for manure and confirm the economic benefit. Ideally, the grower will want a dependable source that can supply the needed manure amounts in a timely maner.

Step 2. Determine the fertilizer recommendations for the crop by submitting a representative soil sample to the UF/IFAS Extension Soil Testing Lab at http://soilslab.ifas.ufl.edu which provides a standard soil test for lime and nutrient requirements and standard UF/IFAS nutrient recommendations. Guidelines for sampling poultry manure can be found at https://edis.ifas.ufl.edu/ss495.

As part of step 2, determine the nutrient content of the manure and the rates of application for specific crops. The UF/IFAS Livestock Waste Testing Lab (LWTL) follows the Standardized Nutrient Recommendations and provides the recommended rates calculated on a broadcast-acre basis, i.e., uniformly spread over the surface of the acre. For mulched crops, we recommend applying this amount of manure to the bedded area only, so that all the nutrients in the manure are in the soil under the mulch and available to the crop.

Step 3. Calibrate the manure spreader to apply the recommended rates of manure. A carefully calibrated manure spreader should be used for the manure application that can drop the manure in a wide band in the area where the planting bed will be made. This application technique will place all of the manure in the planting area, resulting in all of the manure ending up in the root zone under the mulch. Information on calibrating manure spreaders can be found at http://www.caes.uga.edu/publications/pubDetail.cfm?pk_id=6428.

Step 4. Apply the manure in timely manner. Manure for mulched vegetable production should be applied as close to planting as possible. It is possible to lose a significant portion of the nitrogen in the manure from volatilization if it is left on the soil surface for several days prior to incorporation (Figure 9).

Credit: J. Jones

Step 5. Following spreading of the manure, the manure should be thoroughly incorporated by rototilling. The drip-irrigation tubing and the plastic mulch can be applied after bedding (Figure 10).

Credit: G. Hochmuth

Collecting Poultry Manure Samples

Vegetable growers should have a plan with the supplier of the manure to be used for crop production so that adequate sampling and analyses can be completed before the fertilizer program is determined. A sample about 1 month ahead of application provides enough time to have the sample analyzed and time to calculate the amount of manure needed. Sampling methods are described in detail in the publication SL 282 Collecting a Poultry Litter Sample for Analysis available at https://edis.ifas.ufl.edu/ss495. Manure should be stored under cover, such as in a concrete-floor stack barn (Figure 11) in the time before field application. A second sample at the time of field application will allow accurate calculation of the nutrients applied from the manure. All samples should be as representative as possible of the bulk manure and carefully packaged for delivery to the laboratory (Figure 12). To see a copy of the manure sample submission form, please go to http://arl.ifas.ufl.edu/ARL_files/formsubmit/webfiles/login.asp.

Credit: J. Jones

Credit: J. Jones

Choose a Laboratory

Growers should consult with the lab that will do the analyses to be sure the recommendations are supported by research. Research documentation should reflect manure use under warm, humid, sandy soil growing conditions. The UF/IFAS LWTL, located at the UF/IFAS Analytical Services Laboratories in Gainesville is an accepted analytical lab for livestock waste analyses in Florida for BMP planning.

Who should use the manure-testing service?

-

Livestock producers who would like to use livestock waste as a nutrient source, soil amendment, or animal feed.

-

Crop producers who plan to use livestock waste for application to cropland.

-

Homeowners who plan to use livestock waste as a fertilizer or soil amendment.

How do I use their service?

Simply contact your local UF/IFAS Extension office personnel. They will make an appointment to discuss your manure management system and provide advice in the collection of waste samples to be analyzed. The laboratory results and specific manure management recommendations will be provided within two weeks via your Extension agent.

What will the laboratory provide?

The UF/IFAS LWTL, located at the UF/IFAS Analytical Services Laboratories in Gainesville, will provide N, P, and K contents, % solids, and pH analyses of livestock waste samples. The following specific analyses will be provided:

-

Total Solids—Is the dried weight of the submitted sample divided by its original weight or volume. Useful in determining the residues from land application.

-

Ash—Is the weight of the dried solids after ignition at 555°C divided by its original weight. The difference between the total solids and ash content is the organic matter in the sample which is useful in determining soil amendment properties and mineralization rates after application.

-

Total Kjeldahl Nitrogen—Is determined by the Kjeldahl procedure which measures the organic and ammonia nitrogen in the submitted sample. This value includes all nitrogen except nitrate and nitrite, which are in low concentrations in manure samples.

-

Ammonium Nitrogen—Is the common inorganic form in which nitrogen exists in waste and waste water samples. Ammonium can be rapidly converted to ammonia gas under basic (high pH) soil conditions. Ammonia is highly volatile and is useful in estimating potential losses of nitrogen before it becomes available for plant use.

-

Total Phosphorus (P)—Is the total phosphorus in the submitted sample as determined by the persulfate digestion, stannous chloride method at the LWTL. NOTE: Results are given as elemental P and therefore must be multiplied by 2.3 to be converted to P2O5.

-

Total Potassium (K)—Is the total potassium in the submitted sample as determined by the ion specific electrode method. NOTE: Results are given as elemental K and therefore must be multiplied by 1.2 to be converted to K2O.

-

pH—Is a measure of the acidity/alkalinity of the submitted sample. A pH of 7 is neutral, a pH less than 7 is acidic, and a pH greater than 7 is alkaline. High pH can increase the volatilization of ammonia from the sample.

For more information about BMPs and implementation on your farm, please see the Water Quality/Quantity Best Management Practices for Florida Vegetable and Agronomic Crops at: http://www.freshfromflorida.com/content/download/63017/1444054/VACBMP_FINAL_2015.pdf.

Also contact your local UF/IFAS Extension office: https://sfyl.ifas.ufl.edu/find-your-local-office/, or visit the EDIS website: https://edis.ifas.ufl.edu.

References

Hochmuth, G. and J. Jones. 2009. Collecting a Poultry Litter Sample for Analysis. SS495. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/SS495

Hochmuth, R. C., G. J. Hochmuth, and M. E. Donley. 1993. "Responses of cabbage yields, head quality, and leaf nutrient status, and of second-crop squash, to poultry manure fertilization." Soil Crop Sci. Florida Proc. 52:126–130.

Hochmuth, R. C., G. J. Hochmuth, J. L. Hornsby, and C. H. Hodge. 1997. "Comparison of different commercial fertilizer and poultry manure rates and combinations in the production of eggplant." Suwannee Valley REC Extension Report 97–20.

Klausner, S. D., V. R. Kanneganti, and D. R. Bouldin. 1994. "An approach for estimating a decay series for organic nitrogen in animal manure." Agron. J. 86:897–903.

Rasnake, M., B. Thom, and F. Sikora. 2000. Using Animal Manures as Nutrient Sources. Cooperative Extension Service, University of Kentucky. http://www2.ca.uky.edu/agcomm/pubs/agr/agr146/agr146.htm