This work was supported by the Research Capacity Fund (Hatch) projects, project award no. 7004457, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture.

Introduction

Persimmons are classified under the genus Diospyros within the family Ebenaceae (Figure 1). This genus includes different species such as the most popular, D. kaki (Japanese persimmon); D. virginiana (common persimmon); and D. lotus (date-plum, also known as Caucasian or lilac persimmon). Persimmons are temperate deciduous trees or evergreen subtropical or tropical trees. Their fruit exhibit a double sigmoidal growth curve, whether seeded or parthenocarpic. Persimmon fruit are widely appreciated for their unique flavor, high nutritional value, and bioactive compound content, including vitamins A and C, minerals, dietary fiber, carotenoids, polyphenols, and antioxidants. Persimmons can be consumed as fresh, fresh-cut, or dried fruit, including freeze-dried and dehydrated forms.

Persimmons are increasingly popular, and consumption has been on the rise worldwide, with noticeable growth in the United States, owing to increased consumer demand. In the United States, California produces most of the country’s crop, the Japanese persimmon. Persimmons were introduced to Florida in the 1870s, and Florida and southeastern Texas contribute minor persimmon production, focusing on both Japanese and American varieties.

Persimmons are climacteric, meaning fully mature fruit continue to ripen after harvest. The postharvest physiology of persimmon fruit lends to significant postharvest challenges affecting the fruit’s quality, shelf life, storability, and marketability. Postharvest losses are attributed to improper handling, physiological disorders, decay, and changes in physicochemical attributes during storage. Effective postharvest treatments and management are critical to maintaining the quality and extending the shelf life of persimmon fruit.

Physiological processes occurring after harvest include respiration, ethylene production, and biochemical changes. These influence quality attributes such as firmness, flavor, and nutritional composition. Understanding these physiological processes and their relationship with storage practices is critical for enhancing the postharvest life and market potential of persimmons. Optimizing storage conditions and developing innovative handling practices can minimize postharvest deterioration of persimmon fruit.

This publication discusses the postharvest physiology and physiological disorders of persimmon fruit, focusing on how postharvest factors affect fruit quality and shelf life. Furthermore, optimum handling procedures are described to help growers, handlers, shippers, and Extension personnel understand how to reduce postharvest losses and improve the storability of persimmon fruit.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

The Anatomy of Persimmon Fruit

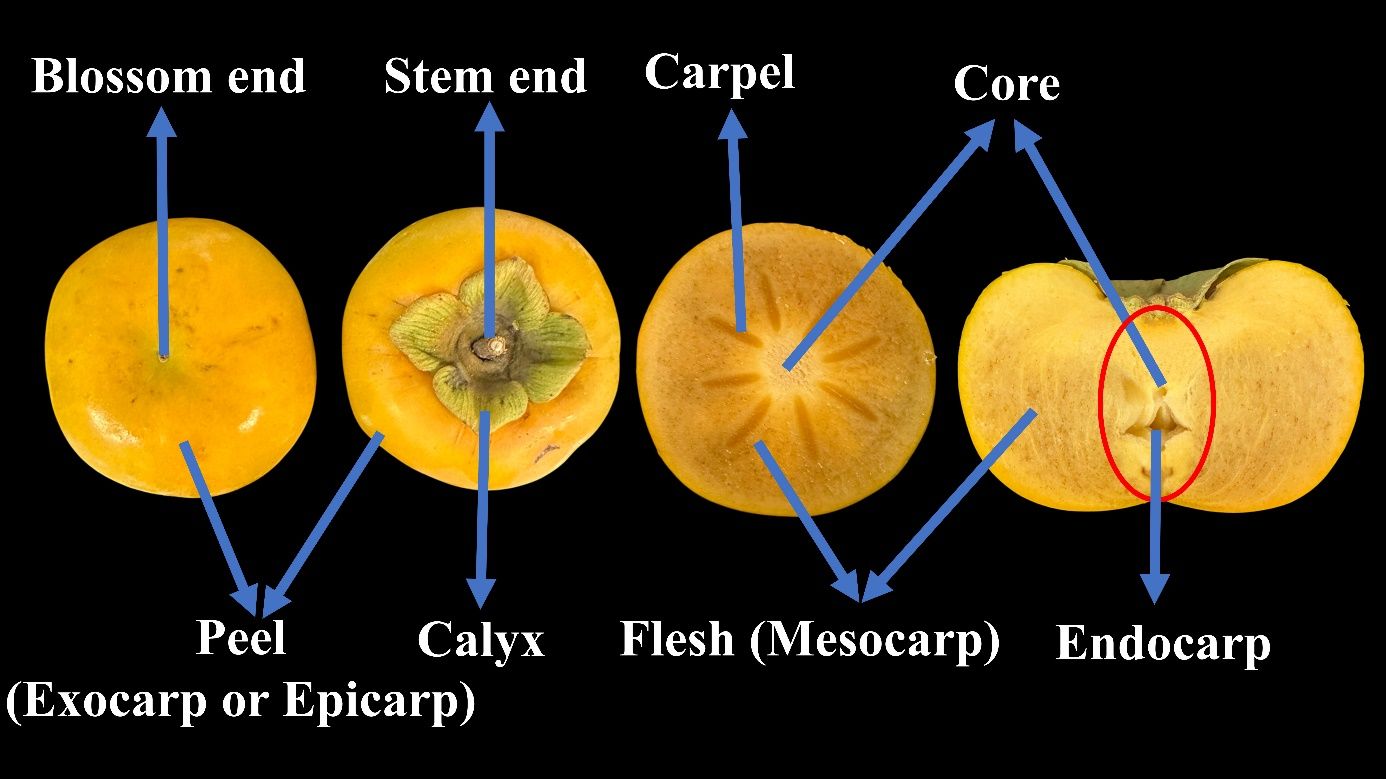

Understanding the anatomy of a persimmon fruit can provide insights into its structural characteristics. Persimmons are botanically classified as berries (fleshy fruit derived from a single ovary). They can be either flat and round (e.g., ‘Fuyu’ and ‘Jiro’) or elongated (e.g., ‘Hachiya’ and ‘Tanenashi’) (Figure 2). The fruit can develop without fertilization (parthenocarpic); these seedless fruit are most preferred commercially, although they tend to be somewhat smaller. A persimmon fruit consists of several distinct parts (Figure 3). The exocarp (epicarp), or outermost layer, forms the peel (skin) of the fruit, which varies in color depending on the variety and ripeness. The peel of persimmons is typically smooth and thin, and its color can range from red to orange or yellow. The peel lacks stomata and lenticels but is covered with a protective waxy cuticle. The mesocarp, or flesh, is the thick, juicy pulp of the fruit. It usually has a sweet, slightly tangy flavor, and its color ranges from pale yellow to deep orange, depending on the variety. The flesh may contain large almond-shaped seeds located in the inner section of each of the approximately eight carpels in fertilized (non-parthenocarpic) fruit (Figure 4). The endocarp, or inner layer that surrounds the seeds (if present), contains tannins that contribute to the fruit’s astringency. The core is the central part of the fruit. The calyx is a green, four-lobed leafy structure at the top of the fruit, surrounding the stem end. The calyx contains chlorophyll. Unlike the fruit peel, it has many stomata and plays a role in gas exchange within the fruit. The stem, also located at the top, marks where the persimmon attaches to the tree.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Maturity

Persimmons are classified as climacteric fruit, experiencing significant color changes and softening as they mature and ripen. The most obvious indicator of persimmon maturation is the external color transformation. The fruit transition from green to pale-yellow orange, finally developing an intense orange-red hue (Figure 5). These color changes result from chlorophyll degradation and carotenoid biosynthesis and accumulation. For best eating quality, the fruit must be fully developed (physiologically mature) by exhibiting the characteristic peel color of the cultivar before being harvested. Most cultivars are considered ready for harvest when they exhibit a full orange to orange-red color without any green background (Figure 6). Color maturity charts, which correlate external color with internal maturity, are valuable tools for making accurate harvesting decisions.

Persimmons are categorized into astringent and non-astringent types, which differ significantly in their eating quality at harvest. Before becoming sweet and edible, astringent persimmons must fully ripen and soften to eliminate their astringency caused by high tannin levels. In contrast, non-astringent types are edible while still firm as they naturally lose their astringency before full ripeness. This distinction is crucial for determining appropriate harvest timing and postharvest handling practices.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Harvesting and Handling

Persimmon fruit are usually harvested between October and November in Florida. It is recommended to clip the fruit from trees using fruit picking scissors (also called harvest clippers or shears), leaving the calyx and a short stem attached to each fruit (Figure 7). Harvesting with a long stem can damage the fruit’s peel and scratch or puncture other fruit during harvest, transport, and storage (Figure 8), increasing the risk of microbial infections and reducing overall fruit quality (Figure 9). Harvesting by pulling or plucking can result in the detachment of the stem in a way that leaves it uneven or torn (Figure 10), which may increase susceptibility to postharvest decays and accelerate quality deterioration (Figure 11). While snapping fruit off the tree is an option, only skilled pickers should attempt this method to avoid fruit injury. Depending on the cultivar and seasonal conditions, the harvest may require one to three pickings before complete. Harvest persimmon fruit in the cool morning hours and handle them gently, as they are easily bruised; picking into a field crate of one or two layers will minimize damage (Figure 12). After harvest, keep the fruit under shade to minimize field heat before transporting them to the packing area.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Persimmon Fruit Types

Persimmon cultivars are typically divided into two groups: astringent and non-astringent (Figure 13). Unripe astringent varieties are known for their mouth-puckering taste, which can numb the tongue and tighten the throat due to the presence of tannins. Therefore, these varieties need to ripen to the fully soft stage to become palatable (Figure 14); they can also undergo artificial treatment to eliminate their astringency as described in the Treatments section. On the other hand, non-astringent types naturally lose their astringency while still firm (at harvest maturity) and can be consumed either firm or soft.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Ripening Persimmons

Ripening of persimmon fruit involves promoting several biochemical and physiological changes that ensure the fruit reach optimal sweetness and texture to increase marketability and consumer acceptance. When harvested at the firm, mature stage, both astringent and non-astringent persimmons continue to ripen when stored at room temperature (Figure 15).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Persimmon fruit soften significantly during normal ripening, a critical factor affecting their marketability and consumer acceptance (Figure 16). Softening is primarily caused by the degradation of cell wall components, such as pectin and hemicellulose, mediated by enzymes including polygalacturonase and pectin methylesterase. During normal ripening, the fruit flesh softens, but the peel stays moist and does not dry out. This is the key difference between softening and shriveling. Shriveling develops during storage under low relative humidity conditions where the peel of a firm fruit loses a significant amount of moisture, resulting in a wrinkled, dry appearance.

In astringent persimmon varieties, ripening is accompanied by a reduction in astringency as soluble tannins polymerize into insoluble forms. Ethylene exposure plays a key role in regulating ripening; however, extended exposure to ethylene can accelerate softening and lead to spoilage. The rate of softening is also significantly affected by storage conditions, including temperature and humidity, as well as preharvest factors, such as cultivar selection and harvest maturity.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

In summary, ripening astringent persimmons naturally at room temperature is a simple, eco-friendly method that allows them to ripen slowly and evenly (Figure 17). This method is energy-efficient and low-effort, making it a sustainable choice. Natural ripening makes the fruit sweeter and less astringent over time, creating a delicious and enjoyable treat. At home, accelerate the ripening by placing the fruit in a paper bag with ethylene-producing fruits like apples or bananas.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Storage and Temperature Management

Postharvest storage of persimmon fruit is crucial for maintaining fruit quality, extending shelf life, and minimizing losses. Persimmons are climacteric fruit and, as such, are sensitive to temperature, relative humidity (RH), and handling conditions. Non-astringent types have a unique sensitivity to chilling injury when stored at 39°F to 59°F (4°C to 15°C). Chilling injury symptoms are flesh browning and premature softening. See the Physiological Disorders section for more information on chilling injury. For maximum shelf life, store both astringent and non-astringent types at 32°F (0°C); this reduces the respiration rate, ethylene production, and water loss, thereby preserving firmness and preventing chilling injury. The key factor is that chilling injury is often most severe at intermediate low temperatures rather than at near-freezing temperatures. Storing at 32°F (0°C) slows down the cellular metabolism and, thus, minimizes chilling-related damage. The highest freezing point is 28.1°F (-2.2°C). Maintaining a 90%–95% RH during storage is important to minimize moisture loss. Cooling as soon as possible after harvest using a forced-air system (high-velocity, cold air) is the fastest means to reach the desired storage temperature and increase shelf life up to three months. Hydrocooling, which involves rapidly cooling produce using chilled water, is generally not ideal for persimmons since they are sensitive to moisture. Excess water can promote decay and fungal diseases, while the force of water may damage the delicate peel, leading to quality issues. For these reasons, storing at intermediate low temperatures and forced-air cooling are often preferred for cooling persimmons without introducing excess moisture. Persimmons are highly sensitive to ethylene (a natural plant hormone that promotes ripening), so store them away from ethylene-producing fruits like apples and bananas for maximum shelf life, unless accelerated ripening is desired.

Establishing and adhering to accepted food safety protocols is critical to minimize the risk of microbial cross-contamination from the field through handling and shipping. Such protocols include sanitizing picking containers, packing surfaces, and equipment, as well as washing/rinsing water and storage areas. Worker personal hygiene is also a key component of a rigorous food safety program.

Shriveling in firm persimmon fruit occurs during extended refrigerated storage under low RH conditions. The primary cause is water loss, which leads to a premature wrinkled appearance, a dry peel, and reduced marketability (Figure 18). Shriveling is exacerbated in firm fruit by physical damage to the fruit's peel, delays to cooling, low relative humidity (RH) during storage, and improper temperature management, all of which increase transpiration rates. Overripe fruit are particularly prone to shriveling due to weaker cell walls and higher water loss. To minimize shriveling, it is crucial to reduce water loss by maintaining high RH (90%–95%) during ripening or during storage at low temperatures 32°F (0°C).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Postharvest Treatments

Removing Astringency in Unripe Fruit

Astringency in persimmons is due to the accumulation of concentrated tannins within the fruit’s flesh. These “condensed tannins” or “proanthocyanidins” are stored in the vacuoles of tannin cells. We taste astringency when the tannins bind to saliva proteins in the mouth. Therefore, reducing astringency is essential for improving the fruit’s palatability for both producer marketability and consumer acceptance. Postharvest methods to reduce astringency involve converting these soluble tannins into insoluble forms. For detailed descriptions on postharvest treatments for removing persimmon astringency, refer to the EDIS publication #HS1483, “Alleviating Astringency in Persimmon Fruit for Enhanced Palatability and Consumer Acceptability.”

Modified Atmosphere Packaging and Controlled Atmosphere Storage

Atmosphere modification has become a common commercial practice to extend the storage time while preserving the quality of many crops, notably apples and pears. It is also beneficial for persimmons. This technology involves placing the crop in a reduced oxygen (O2) and/or elevated carbon dioxide (CO2) environment via modified atmosphere packaging (MAP) or controlled atmosphere (CA) storage. The O2 and CO2 concentrations vary by crop; for persimmons, these are 3% to 5% O2 and 5% to 8% CO2 for best results. Storage under low O2 levels delays ripening, while elevated CO2 concentrations slow softening. The upper tolerable concentration of CO2 appears to range between 10% and 20%, although there are clear cultivar differences. Excessive exposure outside these ranges can cause peel browning and/or flesh browning, starting from the fruit center.

MAP is a passive means for maintaining the desired O2 and CO2 atmosphere within a specially designed package. Selectively permeable membranes modulate gas exchange. This system is commonly used for lettuces and other greens in bulk handling packages and consumer “ready-to-eat” salads. Maintaining the correct gas exchange rates requires a steady temperature, which is sometimes a challenge during commercial handling and marketing.

CA storage is employed in specially designed cold rooms, refrigerated trailers, and marine containers. This system actively removes or adds O2 and CO2 to maintain the desired atmospheric composition around the commodity, extending shelf life up to five months. Using MAP or CA is supplementary to, not a substitute for, storage at proper temperatures. The benefits of this technology depend on cultivar, maturity stage, atmospheric composition, and storage temperature and duration.

Other Postharvest Treatments

As climacteric fruit, persimmons produce ethylene in moderate amounts during ripening. Exposure of mature-harvested, preclimacteric fruit to ethylene reduces shelf life and diminishes marketability by accelerating ripening and fruit softening. Ethylene inhibitors, such as 1-methylcyclopropene (1-MCP), can delay ripening and extend shelf life by inhibiting the action of ethylene. 1-MCP is typically applied in gas form in an enclosed chamber, storage room, or sealed container. Applying 1-MCP to persimmon fruit before cold storage can slow softening and gelation, which are the primary symptoms that limit shelf life. Conduct treatment as soon as possible after harvest to maximize its effectiveness. The recommended dosage is 0.5 to 2 μL L-1 for 12–24 hours at 59°F–68°F (15°C–20°C) in a sealed chamber or storage room. Other postharvest methods include pre-storage treatments like hot water dips, treatment with calcium solutions, and UV-C radiation that can enhance firmness and reduce microbial load. Hot water dips for persimmons typically involve immersing the fruit in water heated to around 113°F–122°F (45°C–50°C) for two to five minutes. Recommended concentrations and doses for these treatments, as well as their effectiveness, depend on the cultivar, fruit maturity, and proper treatment application. When using these methods, small-scale trials are recommended before large-scale implementation to ensure fruit tolerance and optimal results.

Postharvest Physiological Disorders

Chilling Injury

As mentioned above, chilling injury in persimmons is a significant physiological disorder that occurs when the fruit are stored at temperatures between 39°F and 59°F (3°C and 15°C). Development of chilling injury symptoms is time/temperature related; the lower the storage temperature in this range and/or the longer the storage period, the greater the manifestation of chilling injury symptoms. There are also differences in susceptibility due to cultivar. For example, astringent ‘Hachiya’ fruit are not chilling sensitive, whereas non-astringent ‘Fuyu’ fruit are sensitive. Chilling injury symptoms include flesh softening and browning, flesh gelling, off-flavor development, a water-soaked appearance, and increased decay, all of which limit marketability by adversely impacting the fruit’s visual and sensory qualities (Figures 19 and 20). In cases of severe chilling injury, a dark “star” shape can develop around the distal end of the fruit during storage. The full expression of chilling injury is not evident until one to three days after transfer from cold storage to warmer temperatures. In summary, store persimmons at 32°F (0°C) or above 59°F (15°C) to mitigate chilling injury and maximize shelf life. Avoid exposure to ethylene, which can exacerbate chilling injury and hasten ripening.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Peel Browning

The primary external postharvest disorder is peel browning, typically characterized by large, diffuse areas of browning or blackening on the peel. This condition poses a significant challenge to long-term storage, particularly over a 14-week period. Peel browning appears to be associated with high preharvest nitrogen levels. Avoiding nitrogen application within four to six weeks of harvest is generally recommended to minimize this risk.

Peel Spotting

Peel spotting is a disorder that affects long-stored fruit, manifesting as black “pinpricks” on the peel that do not enlarge over time. This issue is likely linked to peel integrity problems and can be mitigated using hot water drenches (131°F [55°C] for 60 s) before storage. While conducting specific tests on Florida persimmons might reduce peel spotting during extended storage periods, further research is needed to confirm their effectiveness.

Summary

Understanding the postharvest physiology of persimmon fruit is essential for maximizing market potential and shelf life, whether for short-term or long-term storage. Key factors affecting postharvest quality include the extent of the respiration rate, ethylene production, and associated biochemical changes. Harvesting at proper maturity, minimizing bruising during handling and packing, and storing under appropriate conditions reduce losses from premature softening. Strategies such as storage at recommended temperatures and RH minimize shriveling and the development of physiological disorders like chilling injury. Using MAP, CA storage, and ethylene inhibitors can further extend shelf life. Furthermore, methods to remove astringency using sustainable ripening techniques provide opportunities to enhance marketability and consumer acceptance of persimmons. By combining these strategies, producers can effectively mitigate losses and deliver high-quality persimmons to the market.

Further Reading

Besada, C., and A. Salvador. 2018. “Postharvest Biology and Technology of Persimmon.” In Postharvest Biology and Technology of Temperate Fruits, edited by S. Mir, M. Shah, and M. Mir. Springer, Cham. https://doi.org/10.1007/978-3-319-76843-4_16

Crisosto, C. H. (2016). “Persimmon.” In The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks, edited by K. Gross, C. Y. Wang, and M. Saltveit. Agriculture Handbook 66. U.S. Department of Agriculture, Agricultural Research Service. https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf

Sargent, S. A., T. E. Crocker, and J. J. Zoellner. 1993. “Storage Characteristics of ‘Fuyu’ Persimmons.” Proceedings of the Florida State Horticultural Society 106: 131–134. https://journals.flvc.org/fshs/article/view/92568

Sarkhosh, A., P. C. Andersen, and D. M. Huff. 2020. “Japanese Persimmon Cultivars in Florida: SP101/MG242, rev. 2/2020.” EDIS 2020 (1). https://doi.org/10.32473/edis-mg242-2020

Sarkhosh, A., F. Habibi, and J. K. Brecht. 2024. “Alleviating Astringency in Persimmon Fruit for Enhanced Palatability and Consumer Acceptability: HS1483, 5/2024.” EDIS 2024 (3). https://doi.org/10.32473/edis-hs1483-2024

Sarkhosh, A., F. Habibi, M. A. Shahid, S. A. Sargent, and J. K. Brecht. 2024. “Dried Persimmon Fruit: A Year-Round Available Product: HS1479, 4/2024.” EDIS 2024 (2). https://doi.org/10.32473/edis-HS1479-2024

Woolf, A. B., and R. Ben-Arie. 2011. “Persimmon (Diospyros kaki L.)." In Postharvest Biology and Technology of Tropical and Subtropical Fruits, edited by E. M. Yahia. Vol. 4. Woodhead Publishing. https://doi.org/10.1533/9780857092618.166