Abstract

Oyster shell recycling programs exist in many coastal communities. These recycling programs are exactly what they sound like. After the meat is consumed, the empty shells are recycled and reused in oyster reef restoration projects. These created or restored reefs serve multiple functions: they help protect the shoreline from strong wind and wave action, and they further serve as the foundation for oyster reefs. This publication is intended to serve natural resources or UF/IFAS Florida Sea Grant Extension agents, as well as local partners who are considering establishing a local oyster shell recycling program or local restaurants interested in learning more about oyster shell recycling. The publication shares lessons learned from starting a program in Miami-Dade County.

Oysters and Their Benefits

Oysters are reef-building, suspension-feeding bivalve mollusks found in near-shore marine and estuarine waters in temperate, subtropical, and tropical zones around the world. The eastern oyster, one of four species found in Florida, creates habitat for other marine organisms by forming a three-dimensional reef on the sediment. Oysters and the reefs they form provide ecosystem services, or benefits humans receive from the environment. In addition to supporting fisheries and providing habitat, oysters can improve water quality. Under optimal conditions, it is estimated that a single adult oyster can filter up to 50 gallons of water per day. Oyster reefs can also help stabilize shorelines. The rugosity, or variation in the height of the reef, reduces wave height and energy from storms, boat wakes, and tides, and consequently slows shoreline erosion.

Oyster Decline

Deterioration of water quality, unsustainable harvesting methods, and disease have reduced oyster reef habitats by 85% globally (Beck et al. 2011) and 64% in North America (Zu Ermgassen et al. 2012), with declines in Florida equally as severe. Oyster reef habitat has decreased by 99% in southeast Florida (Zu Ermgassen et al. 2012) and by 66% in the Big Bend region of northwest Florida (Seavey et al. 2011), while the loss of oysters in Apalachicola in the early 2010s was declared a federal fishery disaster (Camp et al. 2015). The loss of reef habitat due to shell removal reduces the availability of clean, firm substrate needed for spat (immature oyster) to settle on, while the lack of oysters consequently affects the supply of spat. Ultimately, without oysters and substrate for oysters, the ability for oyster reefs to persist and provide ecosystem services is limited.

Oyster Habitat Needs

Oyster shells are the main building block for rehabilitating degraded oyster reefs and creating new ones. The majority of oyster reef restoration projects use an alternative substrate. “Alternative substrate” is an umbrella term used to describe any hard structure that is not native oysters, which is placed into a waterbody for oysters to recruit and grow (Goelz et al. 2020). Traditionally, recycled, fossilized, or dredged oyster shell is used, and oyster shell has been recognized as the preferred substrate, but marl, concrete, limestone, and other engineered materials have also been used in restoration projects (Goelz et al. 2020). Without a firm substrate to settle on, the recruitment of spat (immature oyster) and growth of oyster reefs is limited. Oyster reef restoration projects rely on oyster shell and are often limited by the availability of shell material for restoration to occur. Oyster shell recycling programs offer a way to put shell back into waterways and facilitate the establishment of new oyster reefs.

What Is Oyster Shell Recycling?

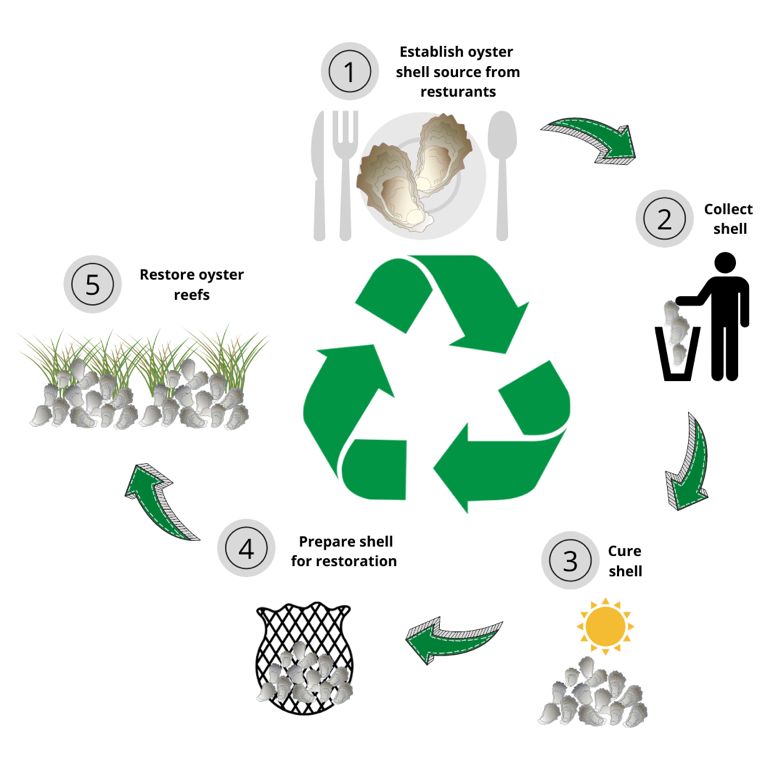

Oyster shell recycling is the process of reclaiming oyster shells after they have reached the final supply chain point (usually the final consumer or customer) so that the shell can be salvaged and repurposed for restoration. Figure 1 illustrates the process of shell recycling. In contrast, the large quantities of shell harvested for consumption are typically thrown away and destined for landfills. Many organizations have created shell recycling programs as a way to collect shells for restoration projects. Shell recycling programs eliminate the wasteful process of throwing shells into the trash by collecting oyster shells and returning them to coastal areas, where they serve as cultch material, or substrate for oysters to settle on and grow.

Oyster shell recycling programs involve partnerships between local restaurants and practitioner groups. Oyster shells are either collected directly from the restaurant or transported to a specific drop-off location. Once collected, recycled shell is set to cure outdoors in a designated area for a certain period of time (dependent upon geographic location; a minimum of three months in Florida but six months in northern locations like Maryland and Virginia) and exposed to the elements and terrestrial scavengers. The curing step is critical because it serves to eliminate harmful bacteria on the shells, while the terrestrial scavengers help to remove any excess meat and tissue. From there, the cured shell is distributed and strategically placed in coastal regions where oysters have been historically found and have the greatest chances for successful reef development. The texture and chemical cues of fresh shell is the preferred restoration material because it is suitable for oyster recruitment and retention, expediting the rate of reef recovery (Tamburri et al. 1992).

Shell recycling programs exist in many coastal communities throughout the state of Florida, and programs in other US states have successfully contributed to oyster restoration projects with measurable results (Bersoza Hernández et al. 2018). The remainder of this document outlines steps for establishing a local oyster shell recycling program and details the partnered UF/IFAS Extension oyster shell recycling program in Miami-Dade County as an example of a successfully implemented program.

The Shell Recycling Process

Credit: UF/IFAS

The steps for collecting oyster shell from a restaurant to an oyster reef restoration project are as follows:

- Establish a centralized oyster shell drop-off location where public participants can take their shell for pickup by the program team at a later date, or establish a partnership with a local restaurant where the program team has scheduled pickup times. The former often requires additional funding to purchase and place collection buckets or bins in the established areas. The latter does not require additional funds if the restaurant can store the collected shell in their existing storage units (i.e., walk-in refrigerator). This step is the largest investment in the process. It requires establishing a rapport and connecting with a local business or seafood market. The largest hurdle is often gaining buy-in: why does this matter, and how will the business benefit from participation? This stage is where education is key. The owner or manager of the business and participating staff need to understand what they are being asked to do (i.e., save the shell when shucking oysters and the other half of the shell that consumers leave on their plate rather than throwing shell into the trash) and why we are asking them to do it. The behavior change that follows will result in increasing amounts of shell recycled. In some states, tax credits are offered to restaurants who participate.

- The next step is the collection of the recycled shell. The shell must be picked up and transported to a drop-off location for curing. Three approaches are commonly identified for collection:

- Have the restaurant collect and store the shell on site until scheduled pickup by the shell recycling group.

- Consumer drop-off: individuals who purchase or consume oysters privately can bring their shell to a location for collection. This usually entails marked collection bins that must be maintained and sorted regularly.

- A dedicated truck picks up shell weekly from restaurants and transports shell to the curing location. There are logistical challenges associated with this method, and it tends to be the most expensive.

In this pilot project, we provided five empty five-gallon buckets with lids to the participating restaurants. Because the buckets were stackable, this required little space in the various businesses’ refrigerator, chosen as the storage location so that there would not be unpleasant odor from the organic material and other food items left on the shell. Depending on the restaurants’ rate of sale of oysters and special events (e.g., “Oyster Happy Hour”), a pickup schedule was set on a weekly or biweekly basis, in which one of the team (UF/IFAS Tropical REC faculty member, Extension agent, student employees and volunteers) would retrieve the full buckets of shell and provide the restaurant with clean, empty buckets to continue collection. The cost of the five-gallon buckets is relatively inexpensive (~$5.00/bucket and lid), so these items were able to be purchased with existing program funds.

- Once the shell is collected and transported, it must be laid out with enough space to cure. In compliance with established regulatory requirements, the shell is set outdoors for three to six months. Shell is often turned to ensure that all biological material is removed, but this is not necessary. Shell must be marked or otherwise tracked to make sure that all incoming shell meets its minimum curing time requirement. The curing time is to ensure not only that all organic material is removed, but that no bacteria or parasites are left on the shell, which could negatively influence future restoration efforts.

- Following the monitoring of the curing time and close inspection of the shell to be free of organic material and smell and slightly whiter in color and more brittle than fresh shell, the fully cured shell is distributed. Depending on deployment methods, some shell is transported loosely. Otherwise, the shell is prepared for restoration. Typically, cured oyster shell is placed into plastic mesh bags (Figure 2). The bagging method is the most common used in restoration practices in Florida and the southeastern United States and is a great way to engage the local community.

Credit: Ana Zangroniz

The final step entails the shells’ distribution to organizations or businesses who focus on oyster reef restoration, living shoreline preservation, and sustainable oyster harvest. With the proper permits, these organizations can place the oyster shell back in the water for their respective restoration project. Florida requires permits for any living shoreline work that is done below the mean high water (MHW) line. You may contact your regional Florida Department of Environmental Protection (FDEP) permitting office for more information, as well as the following UF/IFAS publications:

- A Homeowner’s Guide to the Living Shoreline Permit Exemption, Part 1: Florida Department of Environmental Protection

- A Homeowner’s Guide to the Living Shoreline Permit Exemption, Part 2: United States Army Corps of Engineers

Miami-Dade County Oyster Shell Recycling Program

The UF/IFAS Extension and Florida Sea Grant oyster shell recycling program first began as a pilot project at the 2018 Deering Estate Seafood Festival, a local community event. We placed oyster shell recycling stations around the festival and cultivated relationships with some of the vendors in attendance to collect their shucked shell at the conclusion of the festival. From this singular event, 1,845 oyster shells were recycled (1,120 from vendors, 735 from consumers).

We conducted several informal interviews with oyster shell restoration practitioners around the state of Florida. Through those conversations, we learned that because of the high number of projects, the demand for shell is greater than the supply. While southeast Florida does not have the conditions for successful eastern oyster reef development, the eastern oyster is a popular menu item at a great majority of seafood restaurants, as well as available for bulk purchase at seafood markets. Because local conditions are too warm and saline for eastern oysters to occur naturally in this region, oysters sold by restaurants are imported from other parts of the state and country. Because the oysters being sold in restaurants and markets are usually thrown in the trash and shipped to landfills in the county, an untapped market for shell recycling exists in Miami-Dade County. Recycling shell also benefits the restaurant by saving on disposal fees associated with waste removal.

Following the success of the 2018 Deering Estate Seafood Festival, we created a contact list for Miami-Dade County seafood restaurants that served oysters. After consultation with various restaurants, weekly shell pickups were arranged with a restaurant that had the space to hold shell for one week. Five-gallon buckets were distributed to the kitchen staff to collect shucked shell as well as the half-shell served to patrons. Additionally, we provided the staff at the restaurants with educational items, including flyers for the staff and table tents, explaining the oyster shell recycling process and benefits of oyster reef restoration. Upon hearing about the program, additional restaurants joined the effort the following year.

We coordinated the pickup and transportation of shell. Shell weight and bucket volume data were collected to estimate number of shells before shell was evenly spread onto mesh-covered pallets. A minimum curing period of three months was allowed to ensure exposure to natural elements and predation, removing any remnants of the oyster tissue. While the shells cured, we procured bagging equipment used in oyster reef restoration projects. Equipment consisted of PVC mesh tubing bags (approximately 3 ft in length), an 8 in PVC pipe to help the bags hold their shape, and a funnel to transfer the shell to the bag to prepare for the eventual bagging of the shell. Once fully cured, we held several bagging events that served as educational activities in which Miami-Dade County Florida Master Naturalist Program students weighed and bagged the shell (Figure 2). New bagging material technologies, which do not contain plastic, are being developed and may become the preferred methods for restoration in the future.

Collectively, an estimated 19,650 oyster shells were collected from community events and restaurants in Miami-Dade County from 2017 to 2019. If this oyster shell, weighing 4,843 lb, were transferred to a landfill in Miami-Dade County, it would cost partner organizations $220 in landfill fees. Based on weight, this amount of shell would result in about 242 bags for use in restoration projects. The Choctawhatchee Basin Alliance builds their reefs in 20 ft sections, containing 200 bags, so 242 bags would support the building of 24 ft of oyster reef. If fully functioning reefs with live oysters develop, this shell has the potential to provide $550 worth of ecosystem services annually (Grabowski et al. 2012). While we acknowledge that this is a relatively small amount compared to larger oyster shell recycling programs, the benefits to our partner organizations and the environment serve as foundation and motivation to continue the program, while demonstrating the demand for a larger recycling program within Miami-Dade County.

The shell recycled in Miami-Dade County can be transported to other locations in the state where conditions are more favorable and reefs are able to thrive. UF/IFAS Extension and Florida Sea Grant have researchers and agents involved with or actively participating in oyster restoration projects around the entire state, making the process of finding a restoration practitioner quite feasible. In fact, recycled shells from the Miami-Dade County have been used in living shoreline projects in the Cedar Key area. Over the summer of 2020, partners at the UF/IFAS Nature Coast Biological Station (NCBS) obtained the shell collected in Miami-Dade County and deployed it in a project that intends to test a new restoration material—the oyster reef prism (as opposed to oyster bags or mats). This shell was deployed and is now being monitored by NCBS staff and volunteers. The estimate of oyster volume contributed is 69 cubic feet/2.55 cubic yards/2,898 lb/1.45 tons collected and cured in Miami-Dade County since March 2018. Because all of the aspects of this effort were performed by volunteers, this pilot project has successfully demonstrated that a small-scale oyster shell recycling effort can be employed in-house with minimal external funding. For the program to grow and be successful, additional funding is needed to support staff, travel, and supplies.

Recommendations

1. Designating a coordinator

A “Recycling Program Coordinator” is helpful because of the time commitment of coordinating and following up with restaurant partners, the collection, moving, and maintenance of shell, and maintaining outreach materials and social media accounts. Additional coordinator duties would include managing operations, ensuring consistent and reliable pickups, establishing stakeholder partnerships, and applying for and managing grant funds. Volunteer support is still encouraged, and the recycling coordinator can delegate program tasks to reliable volunteers.

2. Joining an established program vs. creating an independent program

Several established oyster shell recycling programs exist in the state of Florida (Figure 3). Joining an established program has several benefits because messaging, outreach materials, and connections with distribution networks are likely already available. Operating an independent program is necessary when partners do not exist within your area. Creating an independent program requires the additional work of identifying restoration projects in need of shell and creating and maintaining separate outreach materials and a website.

Credit: UF/IFAS

3. Choosing a collection unit

The consensus from other recycling programs is that five-gallon buckets with gamma lids are the most efficient and effective method to collect and transport the shell. Although the gamma lids are more expensive, they reportedly are less frequently lost, and the stronger seal is better at reducing flies and unpleasant smells. Five-gallon buckets are also easy to swap out between pickup and the next collection date. Alternatively, the buckets can be emptied into larger transportation containers (e.g., trash cans in the back of the collection truck), and the collection buckets can be returned to the restaurant to fill before the next collection date.

4. Creating reminders for separating shell

As a result of the high turnover in the restaurant industry, it can be difficult to maintain recycling procedures, even in restaurants that have long participated in the recycling program. Suggestions for mitigating this issue include (1) supplying stickers or laminated flyers to put onto the kitchen wall or shucking counter to remind employees to recycle oyster shells appropriately; (2) supplying collection units of a noticeable difference in color to draw the employees’ attention at the beginning of or during a shift; and (3) asking the restaurant managers to send reminders to the restaurant staff to ensure shell collection remains common operating procedure.

5. Creating outreach materials

Outreach resources should be offered to partners (especially restaurants) to allow them to market and promote their involvement in the recycling program. Organizations recommend having a variety of options available: flyers, trifold brochures, palm cards and business cards, etc., as well as pens, coasters, and banners to promote the program and educate about shell recycling and oyster restoration (Figure 4). A recycling program website or social media pages can serve as an additional asset to the restaurant partners. In addition to providing more educational materials about recycling, these platforms can provide advertising opportunities for partners and act as an incentive for program participation.

Credit: UF/IFAS Advancement

6. Identifying a curing location

The designated curing location requires a large amount of land and needs to be away from residential areas because of the potentially unpleasant smell. A suitable location for curing the shell might not be conveniently located next to restaurants. For example, in Miami-Dade County, shells were cured at the UF/IFAS Tropical Research and Education Center, about 30 miles south of partnering restaurants.

7. Evaluating the program’s success

Several evaluation methods exist for capturing the success of the recycling program. First method: the total weight of oyster shell recycled. Weight can be obtained using a luggage scale to weigh full and empty buckets. The weight of the shell is obtained by the difference. To convert weight to individual shell, we recommend counting individual oysters in at least 10 buckets and using the average to convert from pounds to number of shell. We recommend recording this information upon collection. Second method: the approximate quantity of shell returned to the water in a restoration project. This can be achieved by knowing the weight of bagged shells and number of bags used in the restoration project. Third method: the geographic area of oyster reef recovered (e.g., 50 meters of reef). This success should be tracked based on the recycling program’s goals. Results should be made open-source and freely shared with other interested parties and program partners.

Conclusion

The historical populations of oysters in Florida have been substantially reduced due to a number of factors. Although most oysters sold by retailers or in restaurants are produced via oyster aquaculture, the need for naturally occurring reefs throughout the state remains strong. Oyster shell recycling promotes shell accumulation with the end goal of restoration. Additionally, since the shell is being put back into the environment, it frees up landfill space. Restoration practices utilizing recycled shell create new habitat for oysters to settle on and grow, as well as provide habitat for other commercially and recreationally valuable species such as fishes and crabs, along with other ecosystem services. Investing in shell recycling programs and oyster reef restoration can support Florida fisheries and local economies and can help protect shorelines and improve water quality.

References

Beck, Michael W., Robert D. Brumbaugh, Laura Airoldi, Alvar Carranza, Loren D. Coen, Christine Crawford, Omar Defeo, et al. 2011. “Oyster Reefs at Risk and Recommendations for Conservation, Restoration, and Management.” BioScience 61 (2): 107–116. https://doi.org/10.1525/bio.2011.61.2.5

Bersoza Hernández, Ada, Robert D. Brumbaugh, Peter Frederick, Raymond Grizzle, Mark W. Luckenbach, Charles H. Peterson, and Christine Angelini. 2018. “Restoring the Eastern Oyster: How Much Progress Has Been Made in 53 Years?” Frontiers in Ecology and the Environment 16 (8): 463–471. https://doi.org/10.1002/fee.1935

Camp, Edward V., William E. Pine III, Karl Havens, Andrew S. Kane, Carl J. Walters, Tracy Irani, Angela B. Lindsey, and J. Glenn Morris Jr. 2015. “Collapse of a Historic Oyster Fishery: Diagnosing Causes and Identifying Paths toward Increased Resilience.” Ecology and Society 20 (3): 45. https://doi.org/10.5751/ES-07821-200345

Goelz, T., B. Vogt, and T. Hartley. 2020. “Alternative Substrates Used for Oyster Reef Restoration: A Review.” Journal of Shellfish Research 39 (1): 1–12. https://doi.org/10.2983/035.039.0101

Grabowski, J. H., R. D. Brumbaugh, R. F. Conrad, Andrew G. Keeler, James J. Opaluch, Charles H. Peterson, Michael F. Piehler, Sean P. Powers, and Ashley R. Smyth. 2012. “Economic Valuation of Ecosystem Services Provided by Oyster Reefs.” BioScience 62 (10): 900–909. https://doi.org/10.1525/bio.2012.62.10.10

Lenihan, Hunter S., and Charles H. Peterson. 1998. “How Habitat Degradation through Fishery Disturbance Enhances Impacts of Hypoxia on Oyster Reefs.” Ecological Applications 8 (1): 128–140. https://doi.org/10.2307/2641316

Seavey, J. R., W. E. Pine III, P. Frederick, L. Sturmer, and M. Berrigan. 2011. “Decadal Changes in Oyster Reefs in the Big Bend of Florida's Gulf Coast.” Ecosphere 2 (10): 114. https://doi.org/10.1890/ES11-00205.1

Tamburri, M. N., R. K. Zimmer-Faust, and M. L. Tamplin. 1992. “Natural Sources and Properties of Chemical Inducers Mediating Settlement of Oyster Larvae: A Re-examination.” The Biological Bulletin 183 (2): 327–338. https://doi.org/10.2307/1542218

Walters, L. J., P. E. Sacks, M. Y. Bobo, D. L. Richardson, and Loren D. Coen. 2007. “Impact of Hurricanes and Boat Wakes on Intertidal Oyster Reefs in the Indian River Lagoon: Reef Profiles and Disease Prevalence.” Florida Scientist 70: 506–521.

Zu Ermgassen, P. S. E., M. D. Spalding, B. Blake, L. D. Coen, B. Dumbauld, S. Geiger, J. H. Grabowski, R. Grizzle, M. Luckenbach, K. McGraw, W. Rodney, J. L. Ruesink, S. P. Powers, and R. Brumbaugh. 2012. “Historical Ecology with Real Numbers: Past and Present Extent and Biomass of an Imperiled Estuarine Habitat.” Proceedings of the British Ecological Society 279 (1742): 3393–3400. https://doi.org/10.1098/rspb.2012.0313