Introduction

Florida has recently seen significant increases in the protected agriculture industry for fruits and vegetables. Based on a survey conducted in 2013, the greenhouse hydroponic industry in Florida has seen substantial growth in the past ten years. This growth was in both large (> 3 acres) and small (< 3 acres) growers in Florida, as summarized by Hochmuth and Toro in the publication Characterization of the Florida Fresh Fruit and Vegetable Industry Using Hydroponic Systems or Protected Agriculture Structures (https://edis.ifas.ufl.edu/hs1240). The largest increase in the number of growers has been in the "Very Small Acreage" category (growers with less than one-quarter acre). Technology is available to large growers to manage important decisions regarding heating, cooling, ventilation, shading systems, irrigation, and nutrient delivery. Much of this technology is not affordable to small growers, and therefore, these farmers need to adopt less expensive technology in combination with manual processes to make their systems work on their scale. Perhaps the most challenging aspect of crop management for smaller growers is the proper and efficient control of water and nutrient delivery in a soilless media system. This publication focuses on relatively inexpensive strategies to help small growers know both when to start irrigation events and how long to run a single event when growing in soilless media. As most very small growers tend to use a simple on/off timer, this publication is targeted at those small growers with limited automation.

Knowing the Properties of Your Media

The general plan for managing nutrient solution delivery is to apply the proper amount of solution at a frequency that maintains optimum moisture in the growing media for plant growth, while simultaneously providing for a small amount of leaching during each irrigation event. A small amount of leaching prevents salts from increasing in the media and ensures that all containers receive at least the minimum amount of solution needed to rewet the media. The proper management of the irrigation schedule is important to not waste valuable and expensive nutrient solution by overwatering. In addition, excessive leachate solution can become an environmental concern if it is not collected and reused in some manner. Different media have varying water-holding capacities, and as a result, each grower's production system may require different irrigation schedules. For instance, coconut fiber holds at least twice the amount of water as a similar volume of standard horticultural-grade perlite or composted pine bark. In general, the relative water-holding capacity of standard grades of common media is coconut fiber, pine bark, and perlite, from greatest holding capacity to least. Therefore, every grower should conduct the soilless media water-holding capacity test. To conduct this test, first measure and record the weight of fully dried media in a container or bag. New coconut fiber blocks, rockwool slabs, and loose perlite are considered "dried" as they are shipped, but composted pine bark contains some water and needs to be air-dried in a thin layer spread on a table or floor in a hot greenhouse. Next, fully saturate the media in the container or bag you will use in your growing system (ex. 3-gallon or other size upright bag, 3-gallon or other size plastic nursery pot). Wet the media several times with water allowing any drainage (leachate) to occur; continue draining until the flow of leachate stops. Some coarse media can be difficult to uniformly and fully saturate because the water may channel through the media. If this is the case, it will help to place the media (in the container) in a deep dish and allow the container to sit in water and soak from below over time so that the media is more likely to become uniformly saturated. Mix the media by hand if necessary to assure uniform wetting. The final step is to measure the weight of the saturated media after all drainage has ended. The difference between the wet and dry media is the weight of water in the media each container can hold. Divide the weight of the water by 8.34 (one gallon of water weighs 8.34 pounds). The resulting number provides the volume of water, in gallons, for that container filled with the given media. For reference, a three-gallon upright bag of fine coconut fiber holds approximately one gallon of water. In contrast, horticultural-grade perlite, composted pine bark, and coarse coconut fiber will hold much less water per volume of media, about half of the amount of water held by fine coconut fiber. This test is an important first step for growers, allowing them to know how much nutrient solution each container can hold when filled with a particular media and, thus, how often and how long that media will need to be irrigated. Media with a lower water-holding capacity will need shorter yet more frequent irrigation events because that media will start draining more quickly. Small containers of a low water-holding media are very challenging to keep adequately irrigated.

When to Irrigate

Plants growing in most soilless media will need irrigation several times per day. The number of watering events will increase as the plants grow. It may be sufficient at transplanting to irrigate with one or two short duration events daily. The actual length of such a "short" duration event depends on the emitter flow rate, but an event that supplies an ounce or two per event is often sufficient for a young transplant with a limited root system. As the plants grow, events will need to be increased in frequency. Monitoring the moisture in the media and the amount of leachate will help determine the increases in frequency. Understanding the principles of plant water uptake will help growers plan irrigation events that are set to replace the nutrient solution taken up by the plants during the day. Plants take up water in response to the evapotranspiration process. Evapotranspiration is the process of water loss from the plant (by transpiration) plus losses from the media (by evaporation). More than 95% of the water lost from the plant/media system is lost through transpiration when water vapor is lost from the leaves through the stomata. Night-time irrigation events are not typically needed in hydroponic vegetable production because transpiration is low at night. Warm media and active roots going into the night and cool air temperatures overnight can lead to an increased risk of fruit cracking in crops such as tomato and pepper. To reduce the risk of fruit cracking, growers need to maintain adequate night air temperatures of no less than 60-62 degrees F for tomato and pepper. In addition, very early morning irrigation events should be avoided until plant transpiration rates increase. Each grower will need to determine an appropriate start time by considering temperature and water demand early in the morning. Typically, irrigation events should start well after sunrise, once the greenhouse air warms and plant evapotranspiration rates increase. During the late spring, summer, and early fall in Florida, the first irrigation event should begin shortly after sunrise, perhaps in the first 1–2 hours after dawn. The frequency of events will depend upon the type of media and the size and maturity of the plants. It is expected that a mature fruiting tomato or cucumber plant will use 2–2.5 quarts of water per day during peak harvest, so the number of irrigation events needed depends on how much solution can be held in the media at an irrigation event. Plants growing in high moisture-holding media such as fine coconut fiber may need irrigation 6–8 times daily, whereas plants growing in a low moisture-holding media like horticultural-grade perlite may need a dozen or more shorter events daily.

Duration of an Irrigation Event

The duration of an irrigation event needs to be sufficient to fill the media to 100% water-holding capacity. Additional time is needed to produce a small quantity of leachate, about 10%, but not more than 20% of the total irrigation volume (https://edis.ifas.ufl.edu/cv264). A small amount of leaching is needed to assure that 1) soluble salt concentrations in the media do not increase to damaging levels, 2) all plants receive adequate nutrient solution, and 3) all plants receive adequate irrigation because irrigation systems may not have a 100% application efficiency or uniformity. Not every plant requires the same amount of solution; therefore, if the irrigation time is based on a representative, yet lower-demanding plant, then the higher-demanding plants will be under-irrigated. Excessive amounts of fertilizer in the media can lead to soluble salt burn, especially on young plants or seedlings. Soluble salt burn consists of damage to the roots caused by dehydration and typically appears as marginal leaf necrosis and sometimes slight wilting of the plant. High soluble salt concentrations in the media reduce the capability of the roots to take up water. Tomatoes generally tolerate higher salt conditions than cucumbers, peppers, or lettuce.

It should be noted that the recommended nutrient solutions for crops grown in southern climates are much lower in nutrient concentration than those suggested in cooler, northern climates such as Canada. Florida growers should not follow northern nutrient solution recipes or use the leachate guidelines from those cooler, northern areas. The nutrient solutions used in Florida are typically much lower in concentration, irrigated more frequently, and therefore do not need as high of a leachate percentage because nutrients are replenished more frequently. An unnecessarily high concentration of nutrient solution is not only potentially harmful to the plants, but is also expensive and wasteful. The recommended irrigation practices for greenhouse vegetables in Florida developed by Dr. George Hochmuth are reported in Irrigation of Greenhouse Vegetables—Florida Greenhouse Vegetable Production Handbook, Vol 3, and can be found at https://edis.ifas.ufl.edu/cv264.

Concentration of Nutrient Solution

The control of soluble salt damage begins with the correct formulation of the nutrient solution. The grower should monitor the electrical conductivity (EC) of the nutrient mixture as it is delivered to the plant. This will serve as an indicator that the solution was formulated correctly. Most Florida irrigation water has an EC of 0.5 or less (dS m1) and after the nutrient solutions are made and delivered to the crop, the final EC is usually in the range of 1.5 to 3.5 (dS m1). In most cases, the EC of a young crop starts in the lower range and is increased gradually as the crop matures. Also, the EC of the nutrient solution in growing media should be checked by measuring the EC of the leachate to ensure that the concentrations of nutrients in the media are not building to damaging levels. In a soilless media system, the EC of the leachate from the slabs or bags should not vary more than 1.0 EC units (dS m1) above or below the EC of the applied nutrient solution. If the EC of the leachate is more than 1.0 unit lower than the nutrient solution applied to the crops, then not enough nutrients are being added to the final solution at any one fertigation event. This can be due to improperly adjusted fertilizer proportions or too little fertilizer in the solution in the stock tanks. If the EC is 1.0 unit higher in the media or leachate than the incoming nutrient solution, then the incoming nutrient solution concentration is too high. If the EC of the leachate solution is higher than recommended, then this indicates inadequate irrigation because the plant is rapidly using water and salts are accumulating. Therefore, if the leachate EC is slightly too high (1 unit higher), then the grower can adjust to a new nutrient solution with the correct concentration by adjusting the fertilizer proportioners or diluting the concentration in the stock tank. If the leachate EC is excessive (3–4 units higher) then flushing the media should be done with water. However, after flushing in this manner, the farmer should resume the properly adjusted (likely lower EC) nutrient solution concentration, and not keep giving only water for an extended period of time.

Leachate Collection Systems and Management

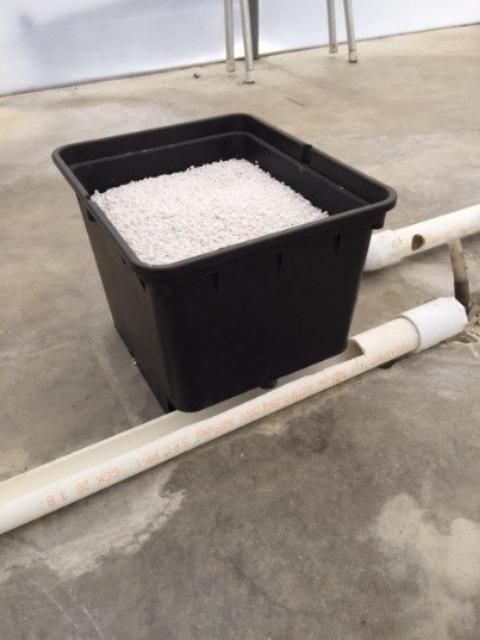

Designing a simple leachate collection system for testing purposes can be as easy as finding materials around the farm or at a local hardware store (Figures 1, 2, and 3). Long, lay-flat slabs can be combined with a metal trough or a piece of large-diameter PVC cut in half. Upright, open bags or plastic pots can use an oil pan drain or a house plant drain dish for catching the leachate.

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

There are plastic or stainless steel leachate collection trays made for rockwool slab systems that may be modified for other lay-flat, soilless media-filled bag designs as well (Figures 4, 5, 6, and 7). The leachate collection systems should be placed in one, or preferably more, normal plant growing locations in the production area. Plants in outside rows are often not representative of normal plant growing areas of interior rows. In fact, it may be helpful to have leachate collection stations for plants on outside rows so you can monitor the variability of plants in outside rows versus the more normal plants on inside rows. The more collection system locations used, the more accurate the collected data will be. But, one well-placed leachate collection site is sufficient as a starting point. One leachate station that is actually monitored properly is better than multiple stations that require so much time that the job is infrequently done properly. The leachate should only be collected from containers with healthy plants. The leachate collection system design should be such that the container of media with the plant never sits in a pool of leachate solution as this will saturate the growing media causing poor growth or even plant death. The process of determining the number and duration of irrigation events will result in frequent changes dictated by weather and crop conditions. Constant attention to this aspect of production will help the grower refine the nutrient program and avoid wasteful and expensive schedules of over-irrigation and over-fertilization.

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

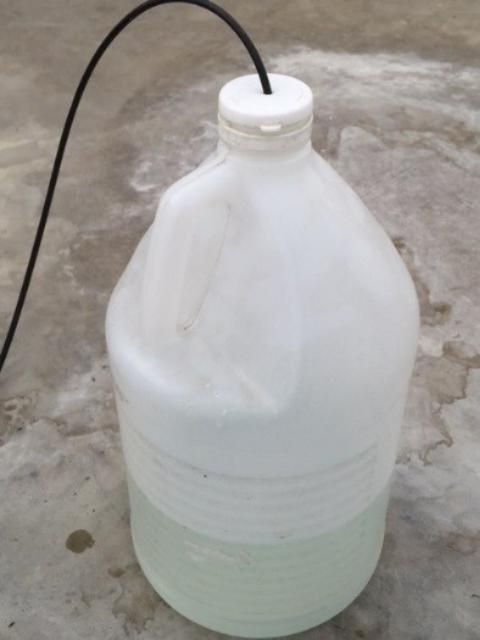

Every grower should have two basic monitoring devices: one to measure the irrigation volume delivered to the crop and one to measure the volume of the leachate leaving the media. Without the data provided by these two measurements, growers are not able to develop an irrigation plan based on actual water use. The volume delivered can be collected and measured using something as simple as an empty plastic gallon container with one extra emitter placed in the top of the container (Figures 8 and 9). When placing the emitter in the container, be certain that the end of the emitter tubing is placed higher in elevation than the irrigation supply line which is next to the rows of media and where the emitters are connected; otherwise, the emitter tubing will continue to drain or syphon solution from the line after the irrigation cycle ends. This will give a false reading of the amount of solution being delivered. The volume collected should be measured and recorded daily. This data should be used to monitor changes in the plant's needs and should be saved from year to year to know when to expect changes and how to refine the overall water and nutrient plans.

Credit: UF/IFAS

Credit: UF/IFAS

The leachate collection is time consuming, but very important. The collection system does not have to be fancy or expensive. It can simply be a plant elevated over a basin to collect leachate. It just has to supply the grower with a means to collect the leachate in order to 1) measure the volume of leachate from each irrigation event, 2) inform the grower of the time required for the irrigation cycle, and 3) gauge the daily adjustments in EC once an initial baseline is determined. The optimum volume of leachate collected should be 10-20% of the total daily volume applied.

In addition to a simple leachate collection system for testing purposes, a good management practice of any farm would be to collect and reuse any volume of leachate coming out of a soilless media system. Most small operations do not typically collect and recirculate the leachate solution because of the expense of sanitizing the solution for diseases and replenishing the nutrients in the solution before it is reused. However, small growers should at least collect the solution and use it for other environmentally sound purposes, such as fertilizing other crops on the farm or ornamental beds and lawn areas for homeowners.

Automated Irrigation Controllers

Soilless media farmers can automate irrigation schedules to varying degrees. The simplest system is one consisting of a time clock that turns on and off an electric valve on preset intervals. More sophisticated irrigation controllers are available, including various digital controllers or computers that control fertigation time, frequency, and other data input parameters (e.g., accumulated sunlight, temperature, scales measuring weight changes of media, etc.). For example, rockwool production systems have a "starter tray" that helps determine when an irrigation event starts by using an electrical circuit and a probe set in a reservoir of nutrient solution. As the solution in the media is used by the plant, the water level in the reservoir becomes lower and the contact with the probe and the solution in the reservoir is broken, resulting in a signal being sent to the timer to start an irrigation event.

Increases in automation can expand the capabilities of nutrient solution mixing and delivery systems, but all automation increases costs. Larger acreage growers should consider higher levels of automation, as they can justify the added costs, which are offset by reduced labor costs and more efficient use of inputs. However, small growers may not be able to afford a very sophisticated automated system. When purchasing a simple irrigation timer, the grower should consider selecting one with the following features: a battery backup to store the irrigation program temporarily, the ability to run for minutes and seconds, the capacity to control an adequate number of irrigation zones for present and future needs, a master valve connection for a solenoid before the injectors, and the ability to enter multiple programs for various run times. Consideration of options to protect the system from lightning and electrical surge is also suggested.

Future Research: Media Moisture Sensors

Recent research has been initiated at the UF/IFAS Suwannee Valley Agricultural Extension Center near Live Oak on the potential use of inexpensive, soilless media moisture sensors. These sensors measure the volumetric water content of the soilless media. The devices are capacitance-type sensors that are responsive immediately to changes in soil moisture content, helping provide information to improve irrigation scheduling decisions. While further testing should be performed for various soilless media, initial research suggests that these sensors are compatible with a fine coconut fiber media, but not coarse media materials such as perlite or composted pine bark. These economical moisture sensors would be another tool, along with leachate collection systems, to provide the smaller grower with valuable information—saving the costly resources of crop nutrients, water, time, and human endeavors.