Vegetables produced in greenhouses require ample amounts of water for optimum growth, yield, and fruit quality. Water is the "universal solvent" in plant cells and is involved in many biochemical processes. Growth processes will slow, and lower yield and quality will result if the plant is without water even for a very short period.

Water is taken into the plant through the root system and exits as water vapor through the leaves by a process called transpiration. Along the way, water is involved in the many processes contributing to growth and yield. As water leaves the plant, the evaporation process cools the plant. Only about 2% of the water that enters the plant is consumed in biochemical reactions. The majority is transpired.

Optimum management of other cultural factors such as disease control is critical to providing for adequate water uptake. Diseased roots, or flooded roots lead to reduced water uptake and wilting.

Relation of Water to Fruit Quality

In addition to affecting overall growth and yield, water management affects fruit quality. Fruit size is reduced in situations where water is inadequate. Water-stressed plants do not develop the dense foliage needed to protect fruit from sunscalding.

A good example of the relationship of fruit quality and water is blossom-end rot (BER). BER is a Ca deficiency disorder that causes fruit cells to collapse and deteriorate. BER is related to water status because Ca moves in the water stream within the plant and is not retranslocated greatly by the phloem system. Therefore, when water supply to the plants is low, an associated deficiency of Ca could occur. Water moves rapidly to the leaves of the plant because transpiration is higher at those locations than in the fruits. Therefore, under water stress, proportionately less water (and Ca) is transported to the fruits. The objective is to maintain healthy plant roots and uniform levels of water and calcium availability to the plants.

Controlling Irrigation

Water stress not only occurs due to inadequate water, but also can result from too much water (flooding). Flooding deprives roots of oxygen that is required for proper root function.

Some type of water-status measuring system is needed to monitor water level in the growing medium. Based on research with various cultural systems, devices and rules-of-thumb have been developed.

In the nutrient film technique (NFT) tube systems, water flow rate is critical since very little "reserve" of water remains in the trough or tube when the pump is off. This is especially true early in the growing cycle when the root mass begins to fill the bottom of the trough or tube and restricts flow rate and drainage. At this time, roots are very subject to flooding damage if the roots are submerged for even short periods.

Flow rates and "pump on/off" cycles, therefore, should be adjusted during the growing season to account for these different situations. Usually the flow rate in the PVC tube system is about 1 to 1½ quarts of water per minute to each tube during the ON cycle. Growers should check to see that all tubes in the house are receiving the same flow. If not, this indicates nonuniform pressure or plugging of the distribution tubing. Early in the season, the clock should be set for 9 to 10 minutes ON and 5 to 6 minutes OFF. As root systems develop, this setting might need to be changed to 8 minutes ON and 7 minutes OFF to provide for additional drainage. Even 5 minutes ON: 10 minutes OFF might be needed if root masses in the tube are very large. The objective is to avoid water buildup at the ends of the tubes. Water flow should be only a trickle from the discharge end of the PVC pipe when the pump comes on for the next cycle. In most situations, settings of 5 or 6 minutes ON and 9 or 10 minutes OFF are required to achieve proper drainage. Pooling of water often leads to problems toward the drainage ends of the tubes resulting in poor growth. This problem arises because the submerged roots lack sufficient oxygen. Hence flooding damage is actually oxygen starvation to the roots. Low oxygen in the root zone reduces the ability of roots to absorb water and nutrients. Eventually, the roots die and can be invaded by disease-causing organisms.

Methods to alleviate flooding problems focus on increasing the OFF cycle. If this is not enough, then the grower can reduce the flow rate at the inlet valve to about 1 quart per minute. Final action might involve increasing the angle of slope on the tube so water flows through the tube more completely. Growers might well consider installing the tubes in such a way as to be able to change the angle through the season. In addition, the tubes should be no longer than 25 to 30 feet.

In the rockwool or perlite systems, water and fertilizer delivery can be controlled by the starter tray described in the fertilizer section of this handbook. Nutrient solution should flow into each rockwool slab or perlite bag at about the rate of 150 ml (one-third pint) per irrigation event. Flow rate of the system and time interval of the ON cycle can be adjusted to achieve this. Another technique which can be used to check on the flow rate is to compare the electrical conductivity (EC) of the incoming nutrient solution with that of the solution leaching from the slab. Usually the leachate volume is about 10% to 20% of the applied volume. The EC of the leachate should not vary more than 1.0 mmhos on either side of the EC of the applied nutrient solution. If the slab solution EC is higher, then this indicates inadequate irrigation since the plants are rapidly using water and salts are accumulating. In other solid-media based cultural systems (e.g., bag culture), water and/or nutrient solution are applied to the run-off or leachate point. In general, recommendations are to set ON cycles to apply nutrient solution up to the point of leaching from the bag or trough.

Water and Nutrient Solution Filtering

Depending upon the source and quality of well water, the grower may need a water filter system on the water supply. Most wells in Florida provide large amounts of sand, clay, and/or limestone particles. Screen or disc filters should be used to filter out the particulate matter, especially if injectors or proportioners are used in the fertigation system. Size of filter screen should be at least 150 mesh to be effective against injector-damaging particles. Removing particulate matter will extend the life of pumps, valves, pressure regulators, and injectors, and is important in reducing emitter clogging.

In general, a high degree of filtering of hydroponic NFT solutions is not required where there is frequent (weekly) flushes of the sump tank. Some particulate matter (algae, sloughed-off root tissue, etc.) will form, but this is usually removed by the flushing sequence. A screen should be installed on the pump intake line to prevent particulate matter (leaves, etc.) from entering the pump.

Water Temperature

Most well water in Florida arrives at the greenhouse at about 68°F–70°F year-round. There is no need to increase the temperature above this except perhaps for seedling germination. In this case, heating water to 80°F for NFT germination of seedlings is beneficial.

The most common problem regarding water temperature is excessively high temperatures of the NFT solution in summer. The flowing solution is gradually warmed as it is circulated within a greenhouse with air temperatures above 90°F. Water temperature above 80°F–85°F may cause reductions in plant growth. Warm water cannot carry as much oxygen as cooler water and higher root media temperatures lead to problems in root function and growth. Root rot problems are more severe where water temperature is too high.

The high-temperature problem is not as severe in rockwool, perlite or bag culture since the applied water always comes directly from the well and is usually not recirculated.

To control excessive water-temperatures, the growth media containers, bags, troughs, and tubes should be either white or reflective on the outer surface. This will help reduce the buildup of warm air in the media.

NFT nutrient solutions will need to be replaced more frequently or will need to be cooled. Cooling of the solution can be achieved by a refrigeration coil system placed in the sump tank. Finally, good control of the ambient greenhouse temperature with exhaust fans, shading, and evaporative pads will assist in controlling nutrient solution temperatures.

Nutrient Solution Oxygen Content

Oxygen is essential for normally functioning root systems. Therefore, the nutrient solution must be able to supply oxygen to the roots or the ON-OFF cycles should be adjusted so that the roots are amply oxygenated. In NFT systems, at least one-third to one-half of the root system should not be allowed to be submerged during the irrigation ON cycle. The roots should be inspected regularly to determine if there is proper aeration. One of the problems with NFT is that the root mat is normally rather shallow, ½ to 1 inch thick, which means that it is difficult to adhere to the 33% to 50% aerated portion rule-of-thumb.

To assist in better aeration of the root system, the sump tank solution should be well aerated. When the return solution enters the tank, it should run over a baffle plate that spreads the solution out into a wide sheet that will gather oxygen, as it drops into the sump. Another technique for aeration of the solution is to install an aerator pipe in the bottom of the tank. This can consist of a one-half inch diameter PVC pipe, with small holes punched every inch. Air is then pumped through the pipe from a small blower or air pump. Several of these pipes might be needed in the tank. Clean, filtered air should be used for injection.

Irrigation Emitter Selection

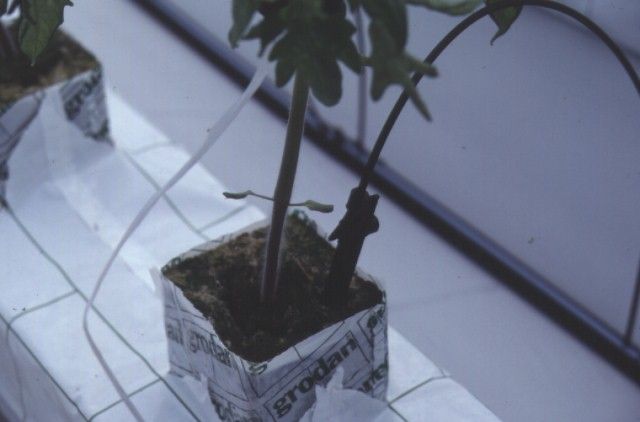

Emitters are the devices that supply the nutrient solution to the individual plants in a rockwool, perlite, or bag system or to the channels in an NFT system (Fig. 1). It is extremely important to choose an emitter that will not easily clog and one that will deliver adequate solution to the crop in a short period of time.

Due to the high potential for clogging in Florida, it is recommended that the emitters and tubing have at least a 0.05 inch inner diameter, especially for rockwool, bag, or trough culture (Fig. 2). Applicators that position the emitter or tube end on a stake above the media surface are desired because they can be easily inspected for flow rate or clogging problems.

Emitter flow rate is a critical aspect of the design of the irrigation system. Growers must be sure that the pump capacity, pipe sizing, pressure regulators, and proportioner pump flow rates are all taken into consideration, so that an adequate and uniform flow rate is realized over the entire house. Systems might need to be reduced into smaller zones to achieve these goals. It is extremely important to design the irrigation system correctly before placing the first plant into the house.

More Information

For more information on greenhouse crop production, please visit our website at http://smallfarms.ifas.ufl.edu.

For the other chapters in the Greenhouse Vegetable Production Handbook, see the documents listed below:

Volume 1: Introduction • Financial Considerations • Pre-Construction Considerations • Crop Production • Considerations for Managing Greenhouse Pests • Summary

Volume 2: Physical Greenhouse Design Considerations • Production Systems • Other Design Information Resources

Volume 3: Preface • General Aspects of Plant Growth • Production Systems • Irrigation of Greenhouse Vegetables • Fertilizer Management for Greenhouse Vegetables • Production of Greenhouse Tomatoes • Greenhouse Cucumber Production • Greenhouse Nematode Management • Alternative Greenhouse Crops • Vegetable Insect Identification and Management