Structural Considerations

Greenhouses can be constructed in a variety of styles that range in size from small stand-alone houses with less than 3000 ft2 of total floor area up to large gutter-connected ranges with over an acre of floor area. Small stand-alone houses typically utilize either Quonset or gable style construction and offer the advantages of low overall initial investment and flexibility of operation. However, they are generally more expensive to construct and are more expensive to heat and cool than larger houses on a square foot basis.

Greenhouse ranges are formed by connecting individual units or bays at the eave or gutter. Each bay's roof can be a gable or arched structure or be sloped to form an element in a sawtooth roof. On an area basis, greenhouse ranges require a lower initial cost than do smaller stand-alone houses. Greenhouse ranges are also easier to heat and cool than smaller houses because they have proportionally less wall space exposed to the outside environment.

Gable and arched bays are the most common types of construction used for greenhouse ranges. Gable types are more expensive to construct than arched types but offer the advantage of being compatible with the installation of ridge vents. Sawtooth roofs are more expensive to construct than arched or gable types but offer the advantage of allowing the use of natural ventilation techniques.

Single greenhouses are normally 20 to 35 ft wide and 90 to 120 ft long. This is a good working size and is easily covered by commercially available sizes of polyethylene sheets. Greenhouse ranges are constructed in sizes that are limited only by the initial cost and the type of management scheme used in the greenhouse operation. If greenhouse ranges are to be mechanically ventilated, then they should be laid out so that air does not have to travel much more than 120 feet from inlet to outlet so that temperature gradients within the greenhouse are kept to a minimum. The height of mechanically ventilated greenhouses should be as low as is feasible for worker comfort to reduce the overall volume that is heated or cooled. Naturally ventilated greenhouses require the use of a ridge vent on a gable roof or a sawtooth roof. This type of roof must be sloped between 3:12 to 6:12 for proper natural ventilation. This will normally result in a higher roof than is required for mechanical ventilation.

The greenhouse structure must be designed to withstand the loads that will be imposed on it during normal use. These include environmental loads such as wind, rain, and loads imposed by hanging baskets or by equipment mounted on the structure. For vegetable production, most greenhouse frames are not strong enough to perform double duty as a trellis support for vegetables. Therefore, it is best to erect a separate trellis system within the confines of the house for vegetables.

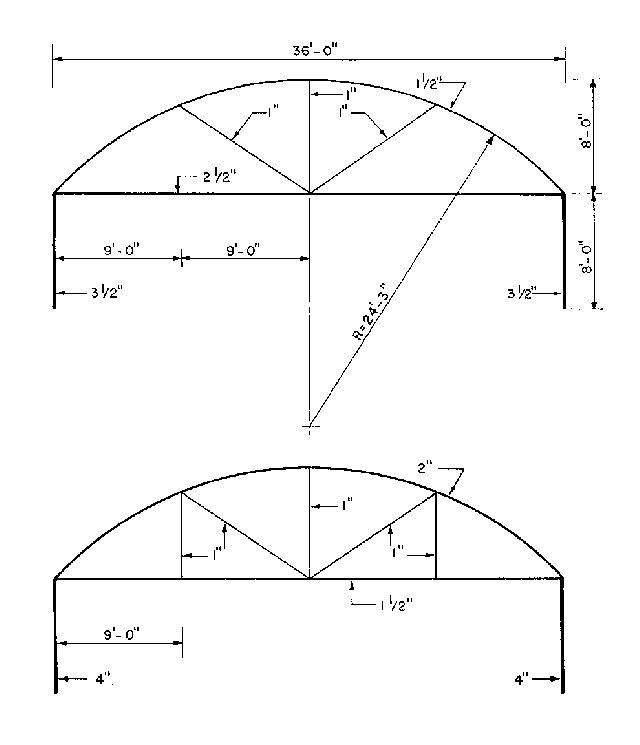

The National Greenhouse Manufacturers Association (NGMA) publishes a standard that gives guidance for the design of greenhouses. It is recommended that every greenhouse be constructed to meet NGMA standards. This factor might be important in obtaining insurance for the greenhouse structure. In Florida, load bearing capacity should be able to handle wind speeds of at least 90 mph. Figure 1 shows two examples of structural tubing truss designs that exceed this minimum load requirement.

Credit: Designs are based on the AISC Manual of Steel Construction, 8th Edition, American Institute of Steel Construction, Chicago, Illinois, 1980.

Greenhouse frames can be constructed of many different materials arranged in different framing systems. Aluminum frames are long lasting, corrosion resistant, lightweight, and can be prefabricated. They can be permanently glazed and have low maintenance requirements. Aluminum frames have a high initial cost and require the services of experienced personnel during construction.

Galvanized steel frames, such as the ones shown in Figure 3, offer high strength and long life at less expense than aluminum frames, although maintenance costs of steel frames may be higher. Metals are good conductors of heat and the heat loss or gain through an aluminum or steel frame can be significant. The high strength of steel makes it possible to use small structural elements, minimizing shading caused by the frame.

Wood frames have a low initial cost but have high maintenance costs. They are also flammable. Painting wooden frames white will improve lighting conditions within the greenhouse. Wood should be pressure treated with preservatives to resist decay. Creosote and penta give off fumes toxic to plants and should not be used. Water preservatives such as chromated copper arsenate (CCA) or ammonium copper arsenate (ACA) are the best preservatives to use in greenhouses.

Glazing Materials

Any of a variety of materials can be used to cover greenhouses. Historically, glass was the first material used to glaze greenhouses. Glass is an excellent material when its high initial cost can be tolerated. Glass has a lifetime of 25 years or longer, has low maintenance requirements, and transmits light well. It requires skilled labor for construction and has a low impact strength. High strength grades of glass should be used for glazing. Glass is heavy and requires the use of strong framing with large structural elements that can block light.

In recent years, synthetic sheets and films have replaced glass as the glazing material used in most greenhouses. The most widely used material is polyethylene film. This material is low in cost, lightweight, is available in easy-to-apply wide sections and has a high light transmittance. Unfortunately, it also has a very short life. Regular grades have a lifetime of only nine months in Florida. Ultraviolet stabilized grades, which last from eighteen months to four years, still require more frequent replacement than most other glazing materials. Common grades of polyethylene are transparent to infrared radiation. New grades are becoming available that block infrared radiation and reduce greenhouse heat losses and those that shed condensation.

Other plastic materials have been used to glaze greenhouses with some success, but their advantages are usually outweighed by their higher initial costs compared to polyethylene. Some of those that have been used are polyvinyl chloride (PVC) films and sheets, polyvinyl fluoride films (Tedlar), acrylic sheets (Plexiglass), polyester films (Mylar), and polycarbonate sheets (Lexan).

Fiberglass reinforced plastic (FRP) sheets are widely used for glazing material. Fiberglass is composed of glass fibers embedded in a polyester resin. Fiberglass sheets are less expensive than glass but more expensive than polyethylene. They are lightweight and impact resistant compared to glass. They have a fairly high light transmittance that is slightly less than that of glass and polyethylene, and fiberglass covered greenhouses are easy to fabricate. FRP sheets degrade when exposed to ultraviolet light Their ultraviolet resistance is improved by the use of polyvinyl floride coatings and acrylic additions to the polyester resin.

Glazing materials must transmit the maximum amount of sunlight to the crop while also holding heat gain or loss to a minimum. The use of double layers of film can add insulating value to the glazing system with only a small reduction in light transmittance. When polyethylene film is used, this system is called double poly. Double poly construction utilizes a small fan to inflate the area between the two layers. This dead air space greatly improves the insulating properties of the greenhouse. When compared to a single layer of polyethylene film, the double poly system reduces heat loss or gain by 35%–40% with a 10% reduction in light transmission. A tightly inflated double poly greenhouse is more resistant to wind damage than a single poly house and most fiberglass greenhouses; however, a double poly greenhouse requires more maintenance to keep the double poly system properly inflated and a good polylock system is required to seal the layers of polyethylene together at their seams.

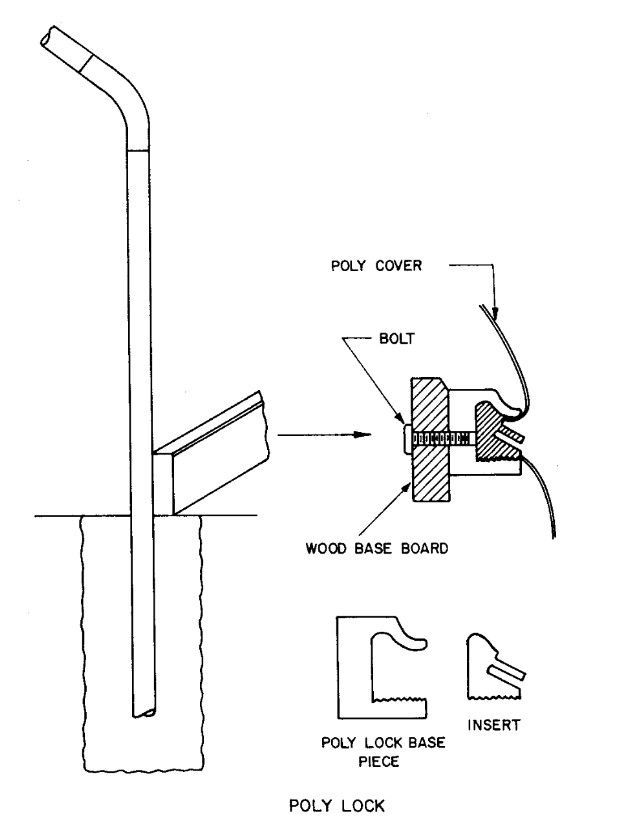

Polylock Extrusion Systems

The polylock extrusion system is the set of aluminum extrusions that will hold the poly cover on the greenhouse frame. Typically, the system consists of, at least, baseboard and end wall (arch) aluminum extrusions and the accompanying inserts. The extrusions are mounted to the steel side columns and the endarches. Mounting procedures differ slightly depending on the greenhouse manufacturer. Houses with tall, straight sidewalls will have a third extrusion that mounts to the top of the column called an eave extrusion. The top of the eave extrusion holds an edge of the poly roof cover, and the bottom of the extrusion holds the top edge of the sidewall poly. The method by which the poly cover is fastened in the extrusion varies with greenhouse manufacturer. Some kits will use an insert that wedges the poly into a groove in the extrusion. The insert simply pops in place with the use of a special wedge tool. The extrusion/insert system is designed so that the normal "pull" of the poly tends to naturally tighten the hold of the insert; an example is shown in Figure 2.

Credit: UF/IFAS

Other manufacturers use systems that rely on bolts and clamps. The main point is to purchase a system that will perform well by holding the double poly cover in place against any weather situation. Some hydroponic growers who install concrete floors might look for an extrusion system that uses a wide baseboard poly extrusion. The baseboard extrusion can also function as a concrete pouring form.

It is important not to compromise quality for price in the poly extrusion system. The extrusion system is one of the most expensive parts of any good greenhouse and a fail-safe system will keep the poly on the house until it is removed. The buyer may have to mix and match in order to get the right extrusion on the house, particularly if the person is providing his own pipe work.

Ground Cover

For soil or bag production systems, there must be a permanent barrier between the crop and the native soil beneath the house. Native soils have populations of nematodes and pathogens that are easily introduced into greenhouse operations and very difficult to control. Any of several root nematodes and other vegetable nematodes are commonly found in most native soils. They can get into a greenhouse whenever the barrier between the crop and the native soil beneath the house is broken. A single root penetrating through the plastic, concrete, or other flooring material can provide a route of entry. For ground style production of vegetables, house design should minimize vertical support posts to allow effective understerilization of the production floor area.

Concrete walkways between rows in the greenhouse and between buildings not only facilitate moving materials but can improve sanitation. Walkways "control" the movement of traffic into and around the production area and can minimize tracking contaminated soil or plant material into the greenhouse. This is an important consideration because prevention of nematode infestation is a much surer management strategy than any curative treatment.

Sealing the Greenhouse

Greenhouses should be built with an "airlock" entrance design (Figure 3). This entrance porch prevents direct ingress of wind, insects, soil, and spores into the greenhouse. Such an entrance has the additional advantage of making doors easier to open and close when the fans are operating. The double entrance also prevents short-circuit air flow patterns when ventilation fans are in operation.

Credit: UF/IFAS

Horticultural Considerations

Single greenhouses to be used for tomatoes and cucumbers should be sized to provide enough space for 5 to 6 double rows of plants. Sidewalls should be high enough to permit close placement of outside crop row to sidewall with enough room on the outside to allow access to the crop. Therefore, sidewalls should be at least 5 to 6 feet tall.

Tomatoes and cucumbers require trellising to maximize utilization of space and to facilitate crop management. Heavy galvanized steel pipes or "I" beams are used at the ends of the trellis to anchor the wire. Secondary supports or props will be needed down the row to prevent sagging of the wire under heavy fruit load. More detail on specific trellises can be found in Volume 3 of this handbook.

The same type of greenhouses can be constructed for lettuce, pepper, and herb production. Lettuce and herbs are usually produced hydroponically in small troughs on benches. Bench production helps facilitate crop management and provides for a cleaner product.

When designing the physical layout inside the greenhouse, flexibility should be kept in mind. Even though tomatoes, for instance, may be the intended first crop, factors may change that will force one to either grow another crop or more than one crop. Row spacing requirements, trellis design, and irrigation design should be researched before the final layout is chosen. One should try to incorporate as much flexibility as possible into the layout design so that changes can be quickly made if necessary.

Adjacent Facilities

Adjacent facilities for properly storing and handling growing media should be provided. Any component of the growing media that was never sterilized or has been exposed to contamination during storage and handling can introduce nematodes. Concrete bins that are cracked, allowing weed roots to grow through from native soil, can carry infestation into the soil mix. Run-off from heavy rains, contaminated with field soil, that flows across the storage or mixing area can also do the job. Using machinery that has been used for field operations to mix or move growing media can contaminate it. If transplants will be produced on site, a totally sterile facility should be built for that purpose.

More Information

For more information on greenhouse crop production, please visit our website at https://nfrec.ifas.ufl.edu/ [September 2011].

For the other chapters in the Florida Greenhouse Vegetable Production Handbook, see the documents listed below:

Volume 1: Introduction • Financial Considerations • Crop Production • Summary

Volume 2: Physical Greenhouse Design Considerations • Production Systems • Other Design Information Resources

Volume 3: Preface • General Aspects of Plant Growth • Production Systems • Irrigation of Greenhouse Vegetables • Fertilizer Management for Greenhouse Vegetables • Production of Greenhouse Tomatoes • Greenhouse Cucumber Production • Alternative Greenhouse Crops • Vegetable Insect Identification and Management